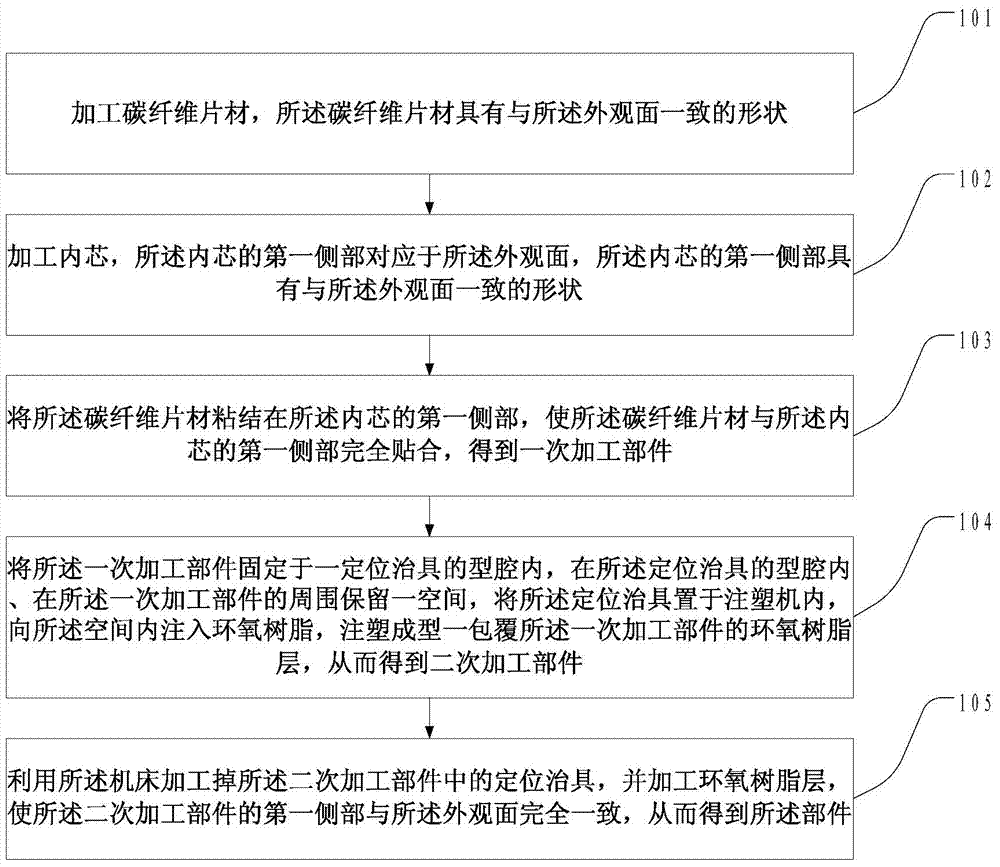

Machining method for mobile phone model product part having carbon-fiber effect

A mobile phone model and processing method technology, applied in the field of component processing, can solve the problems of curved surface folds, poor appearance of model products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

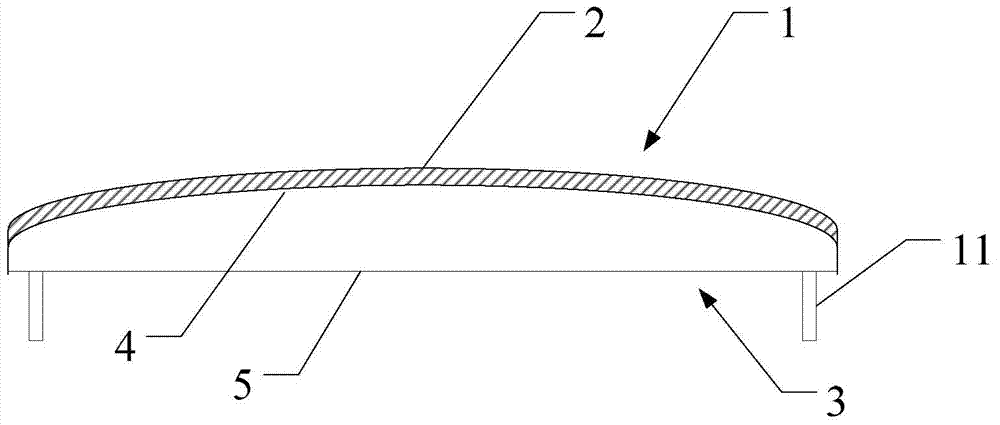

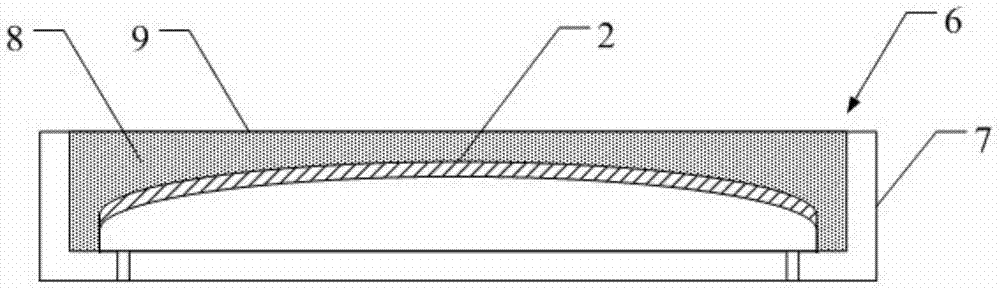

[0058] Embodiment 6 and Embodiment 10 process the cell phone battery cover with carbon fiber effect, wherein, except for the conditions given below, the processing process of Embodiment 6 to Embodiment 10 is consistent with Embodiment 1. Embodiment six to embodiment ten comprise following processing procedure:

[0059] According to the 3D drawing of the customer's mobile phone battery cover, a transparent acrylic mold for carbon fiber sheet thermoforming is designed. The mold cavity has the same shape as the appearance of the mobile phone battery cover; according to the 3D drawing of the customer's mobile phone battery cover File, design and process the inner core with a thickness less than 1mm than the design size in the drawing file.

[0060] The carbon fiber effects of the mobile phone battery covers from the sixth to the tenth embodiments are all good, and the average production cycle is 17 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com