High-gloss low-filling halogen-free hybrid flame-retardant PC (polycarbonate) material as well as preparation and application thereof

A low-filling, high-gloss technology, applied in the low-filling, halogen-free hybrid flame-retardant PC material and its preparation and application, high-gloss field, can solve the problem of smoke density and heat release not meeting the requirements, adding more fillers, etc. problem, to achieve the effect of reducing smoke density and heat release, improving compatibility and high surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of PC material comprises:

[0054] According to the proportioning of Table 1 and Table 2, mix other components except methyl methacrylate-styrene grafted nano-titanium dioxide (or nano-titanium dioxide) and zinc borate, and feed them into the main feed of the twin-screw extruder. Feed methyl methacrylate-styrene grafted nano-titanium dioxide (or nano-titanium dioxide) and zinc borate into the twin-screw extruder from the side feed port, and melt extrude to obtain PC material, wherein the extrusion temperature is 260°C-280°C ℃.

[0055] Performance Testing:

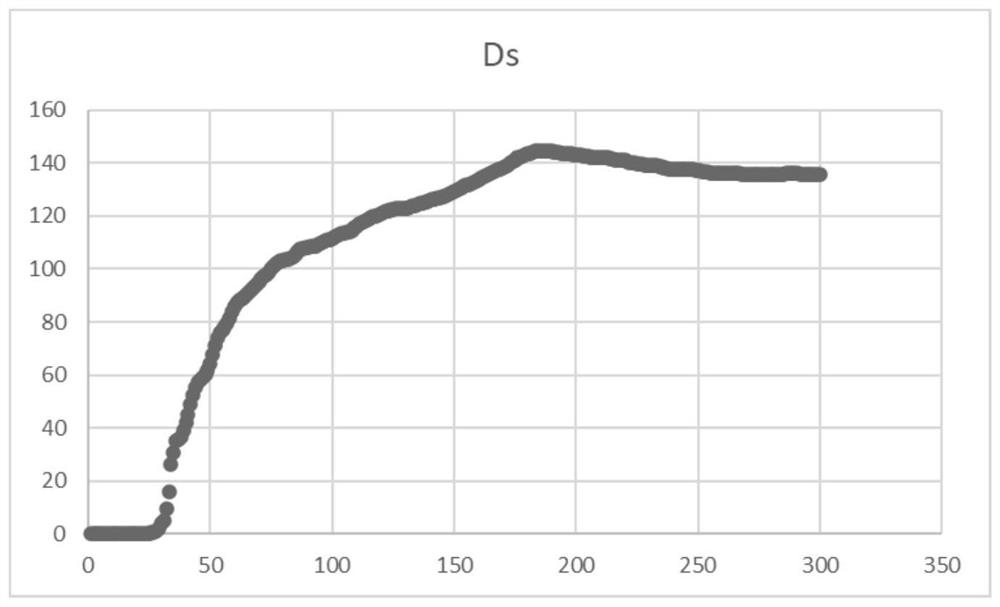

[0056] (1) Smoke density (Ds4min): according to ISO5659-2 standard, 50kW / m 2 Flameless, hazard level: HL1≤600, HL2≤300, HL3≤150;

[0057] (2) Smoke density (VOF (4min)): according to ISO5659-2 standard, 50kW / m 2 Flameless, hazard level: HL1≤1200, HL2≤600, HL3≤300;

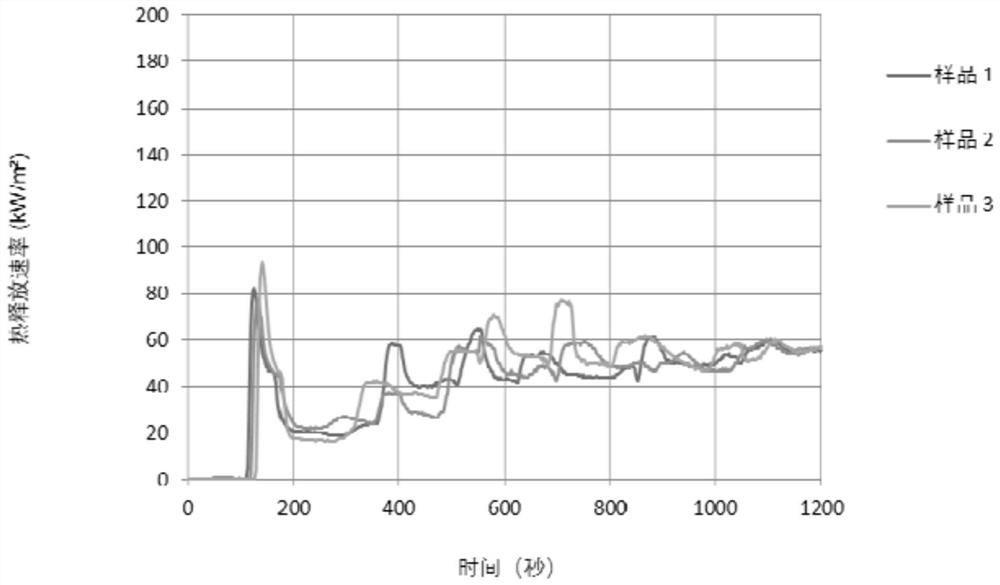

[0058] (3) Heat release (MARHE): According to ISO5660-1 standard, 50kW / m 2 , hazard level: HL2≤90kW / m 2 , HL3≤60kW / m 2 ; ...

Embodiment 3

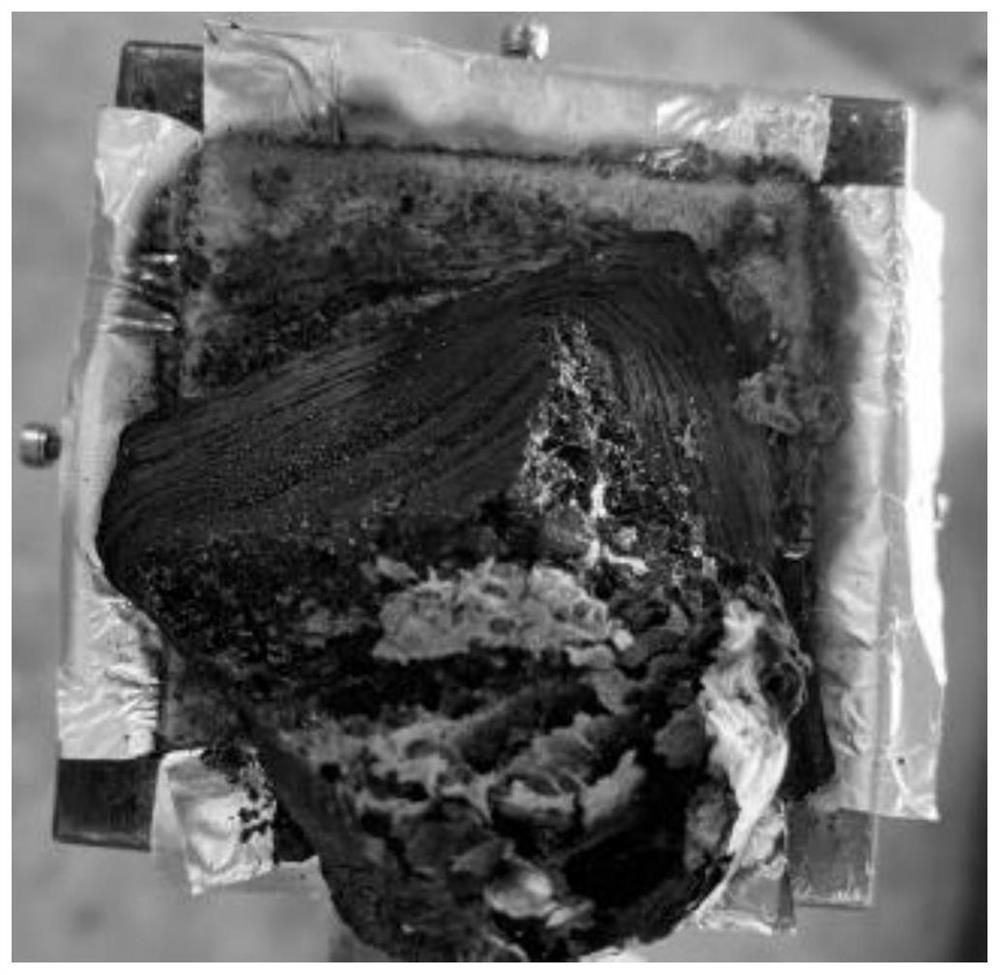

[0067] In Example 3, the flame retardant 3 content is higher than that in Example 2, and the heat release in Example 3 is reduced, and the smoke density is increased. The carbon layer expands to reduce the heat release, reducing the heat release to below 60, reaching 2 heat release.

Embodiment 6

[0068] In Example 6 and Example 5, the content of flame retardant 2 is higher than that of Example 4, and the heat release of Example 5 and Example 6 decreases gradually, and the smoke density still rises slowly. This is because flame retardant 2 has the effect of isomerized PC. Therefore, its smoke density and heat release are high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com