A deformation compensation device used on the frame of injection molding machine or die-casting machine

A deformation compensation and die casting machine technology, applied in the field of deformation compensation devices, can solve the problems of increasing movement, relative deformation of fixed molds, affecting the shape of injection molded products, etc., and achieves the effect of saving power source, improving production efficiency, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

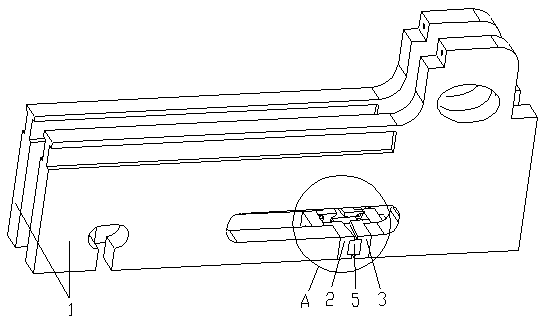

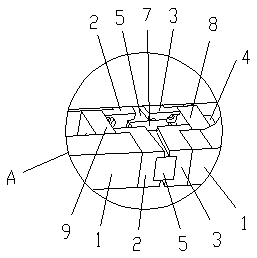

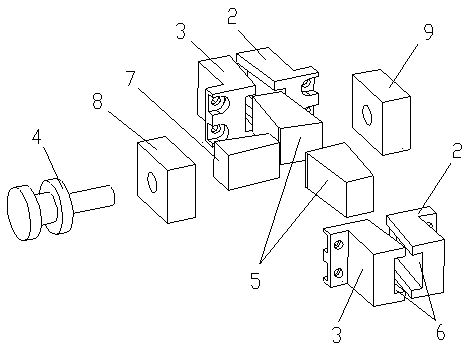

[0025] see Figure 1-2 , part A in the accompanying drawings is the deformation compensation device for injection molding machine or die-casting machine frame of the present invention, which includes a pair of guide blocks 2 and 3 embedded in the side plate 1 under the frame, The two guide blocks 2 and 3 are arranged at intervals along the compression direction of the side plate 1; an expansion device, the expansion device is arranged between the two guide blocks 2 and 3, and Under the action of the driving device 4, the guide block 2 and the guide block 3 are driven to move in the direction opposite to the side plate 1 being pressed. When the movable template and the fixed template on the frame are clamped, the frame at the movable template and the fixed template is respectively subjected to a reverse force, which is transmitted to the side plate 1 below the frame. At this time, under the action of the driving device 4, the expansion device drives the guide block 2 and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com