Pressure machine

A technology of presses and glands, applied in the field of presses, which can solve the problems of increased cost, instability, and difficulty in disassembly, etc., and achieve the effects of preventing axial series movement, firm connection, and increasing lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below through specific embodiments. It should be pointed out that for those of ordinary skill in the art, without departing from the principle of the present invention, some modifications and improvements can also be made, and these should also be regarded as belonging to the present invention. protection scope of the invention.

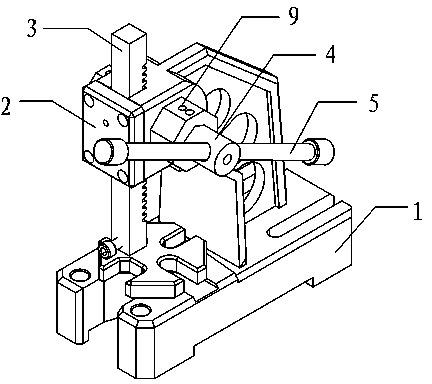

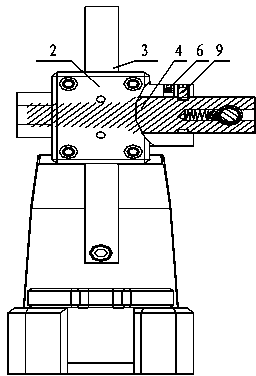

[0014] Press machine of the present invention such as figure 1 , figure 2 As shown, it includes base 1, gland 2, rack 3, pinion 4, handle rod 5 and marble oil cup 6; gland 2 is arranged on base 1; rack 3 passes through the gland arranged on base 1 2. One end of the rack 3 coincides with the groove on the base 1; the pinion 4 is arranged on the base 1; the pinion 4 is connected with a handle rod 5; the base 1 is provided with a marble oil cup 6. The pinion oil cup 6 is used for adding lubricating oil between the gear shaft 4 and the base 1, which can effectively prevent impurities such as dust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com