Manufacturing and installation method of foamed aluminum floor for passenger cars

A technology of foamed aluminum plate and production method, which is applied in the field of passenger car body, can solve the problems of difficult fixation and poor installation process, and achieve the effects of good heat resistance, light weight of the car body, and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

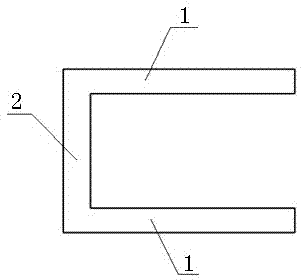

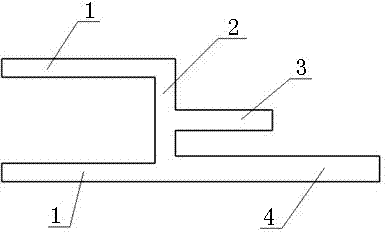

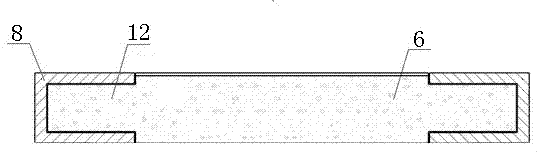

[0033] see Figure 1-Figure 4, a foamed aluminum floor for a passenger car, comprising a foamed aluminum plate 6, each side of the foamed aluminum plate 6 is divided into an installation edge near the edge of the compartment, and an overlapping edge adjacent to two foamed aluminum plates 6 on the plane of the compartment floor, the foam When the aluminum plate 6 is connected to the steps in the compartment, the side is the installation side, and the installation side is inlaid with a head profile 8 with a groove-shaped cross section, and the overlapping edge is inlaid with a groove-shaped cross-section. , and on the other side of a profile clamping edge 1, there is an overlapping profile 10 with a profile fixed edge 4, the head profile 8 and the overlapping profile 10 are both made of aluminum alloy, magnesium alloy or iron metal. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com