Chain hoisting mechanism of coarse spinner

A roving frame and chain technology, applied in textiles and papermaking, etc., can solve the problems of inability to open or close, the top of the hanging spindle is broken, and the hanging spindle cannot be lifted in place, etc., so that the installation and disassembly process is convenient and simple, and the efficiency is improved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

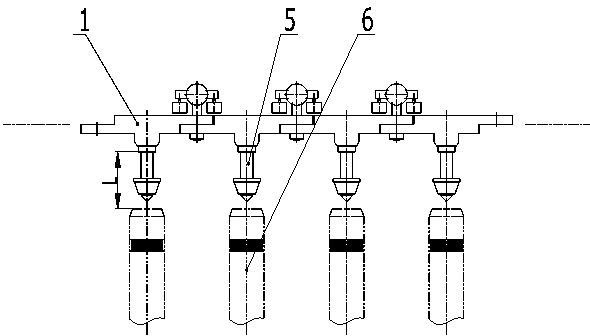

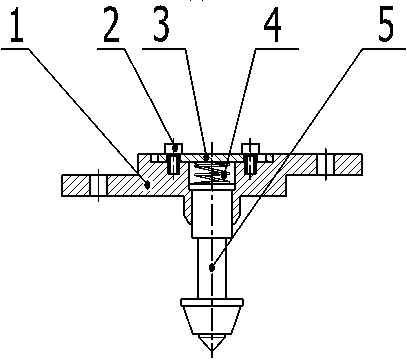

[0014] Example 1: Such as figure 1 , 2 As shown, a chain hoisting mechanism for a roving frame includes a chain piece 1, a cover plate 3, a spring 4 and a hanging spindle 5. The upper part of the hanging spindle 5 passes through the center hole of the chain piece 1, and the boss on the inner wall of the center hole Support, to ensure that the hanging spindle 5 will not slip out of the center hole, the top of the center hole is closed by the cover plate 3, the cover plate 3 is firmly fixed on the chain piece 1 through the fastener 2, the spring 4 is a pressure spring, and the two ends Respectively connect the top of the hanging spindle 5 and the cover plate 3, because both ends are compressed, so the spring 4 itself has a certain pre-tension force, which is greater than the force required to trigger the action of the hanging spindle 5 itself, so the bobbin 6 is in the During the continuous jacking up of the bottom, until the suspension spindle 5 is triggered to move, the sus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com