Combustor capable of laterally feeding biological particles, and working method thereof

A technology of biological particles and burners, which is applied in the direction of combustion equipment, solid fuel combustion, lighting and heating equipment, etc., can solve the problems of incomplete combustion of fuel, waste of fuel, and non-environmental protection, so as to improve combustion quality and reduce fuel waste , the effect of adequate oxygen supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

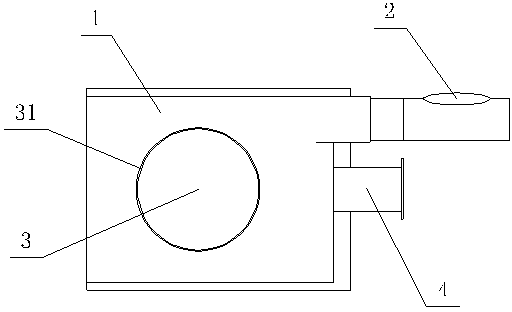

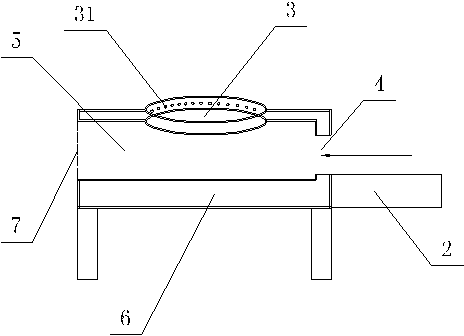

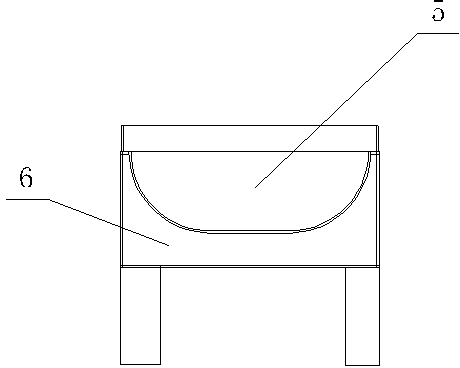

[0018] refer to Figure 1 to Figure 3 As shown, a side-feeding biological particle burner and its working method include a burner body 1, a blower 2 arranged on the burner body 1, and a gasification chamber 5 penetrating through the side wall of the burner body 1, and setting The feed port 4 at one end of the gasification chamber 5, and the slag outlet 7 arranged at the other end of the gasification chamber 5 opposite to the feed port 4, and the ventilation chamber 6 arranged below the gasification chamber 5, and through A small hole (not shown) on the bottom surface of the gasification chamber 5 communicating with the ventilation cavity 6, and a combustion hole 3 arranged on the top of the gasification chamber 5; the inner wall of the combustion hole 3 is provided with a sufficient oxygen hole 31; The air outlet of the blower 2 communicates with the sufficient oxygen hole 31 and the ventilation cavity 6, and supplies air to the sufficient oxygen hole and the ventilation cavit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap