Monitoring method and monitoring system for progressive damage of corrugated composite wing cover

A composite material and progressive damage technology, which is applied in the fields of biology, industrial production, and aerospace, can solve problems such as errors and recognition errors, and achieve the effect of simple structure and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

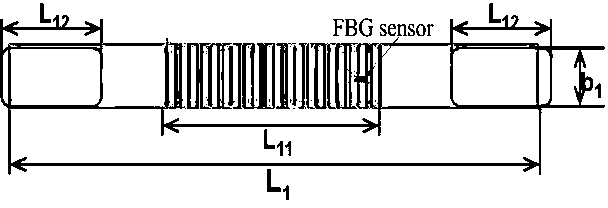

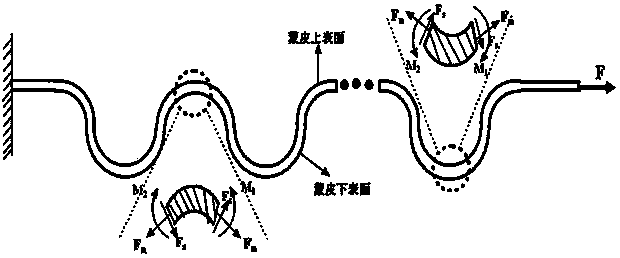

[0027] A progressive damage monitoring method for corrugated composite wing skin disclosed by the present invention includes skin finite element analysis, ply failure prediction and reflection spectrum reconstruction, and experimental monitoring. After obtaining and verifying the accuracy of the predicted failure spectrum , the skin specimens of the same batch and style can monitor the progressive damage of the skin only by observing the changes in spectral characteristics and the number of spectral splitting recorded by the spectrometer.

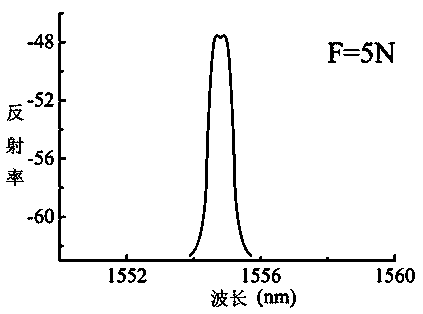

[0028] The core key of the present invention lies in the change of spectral characteristics in the progressive damage monitoring method of the corrugated composite skin, that is, the change of the central wavelength, spectral width and spectral shape of the FBG non-uniform reflection spectrum, specifically the drift of the central wavelength, The spectral width becomes wider, initial splitting appears on the left side of the initial peak, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap