Glass droop testing platform

A testing platform and glass technology, applied in the direction of material inspection products, etc., can solve the problems of unable to truly reflect the physical and chemical properties of glass, unable to reasonably counteract the physical and chemical properties of glass, misleading the adjustment of glass frit parameters, etc., to achieve stable product quality. Controllable, ensure long-term accuracy, and avoid the effect of test errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

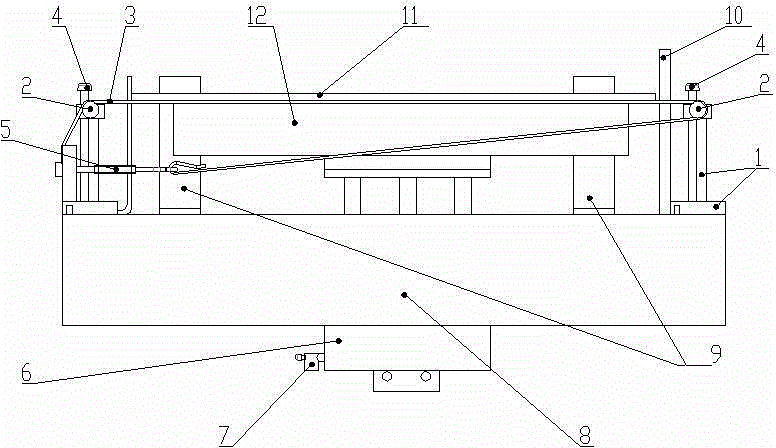

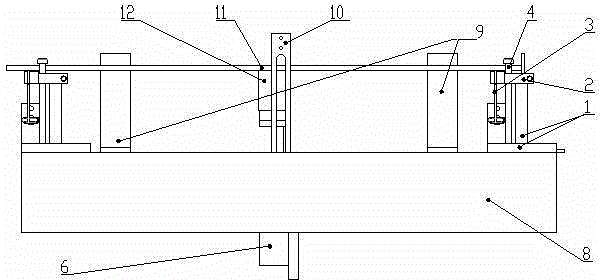

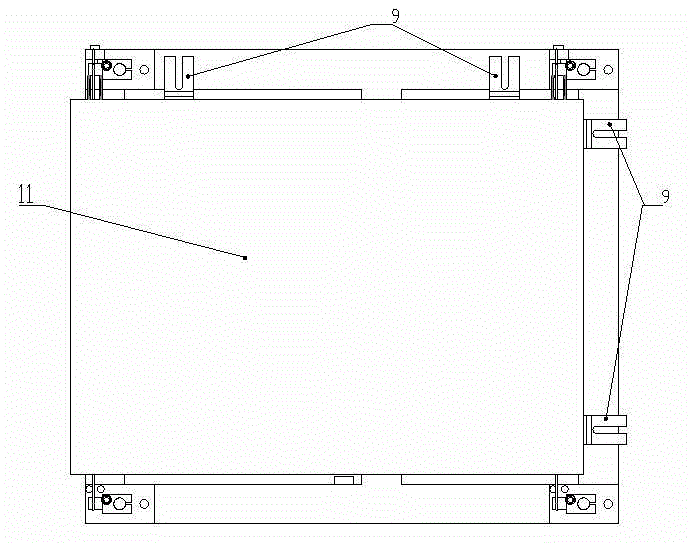

[0016] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0017] It is equipped with a bracket 8, a support plane, a driving mechanism 6, a positioning piece 9, a measuring ruler 10, and an adjustment mechanism composed of a base 1, a height adjustment block 2 and an adjustment screw 4, and the adjustment screw 4 in the adjustment mechanism passes through the height adjustment block 2 is set on the base 1; the support plane is set on the top of the adjustment mechanism, which is integrated with the adjustment mechanism, and is used to support the glass 11; The position of the test glass 11 is positioned on the support 8 , and the measuring ruler 10 is arranged on the support 8 and is located at the center of the test glass 11 .

[0018] The support plane is the support plane formed by the flexible rope 3 or the cross bar and the support rod 12 .

[0019] The support plane is also provided with a sling 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com