System and method for production process self-adaption monitoring using OCSVM

A production process and process monitoring technology, applied in manufacturing computing systems, data processing applications, electrical program control, etc., can solve the problems of low update speed of monitoring models, failure of monitoring models, slow speed of effectively updating samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

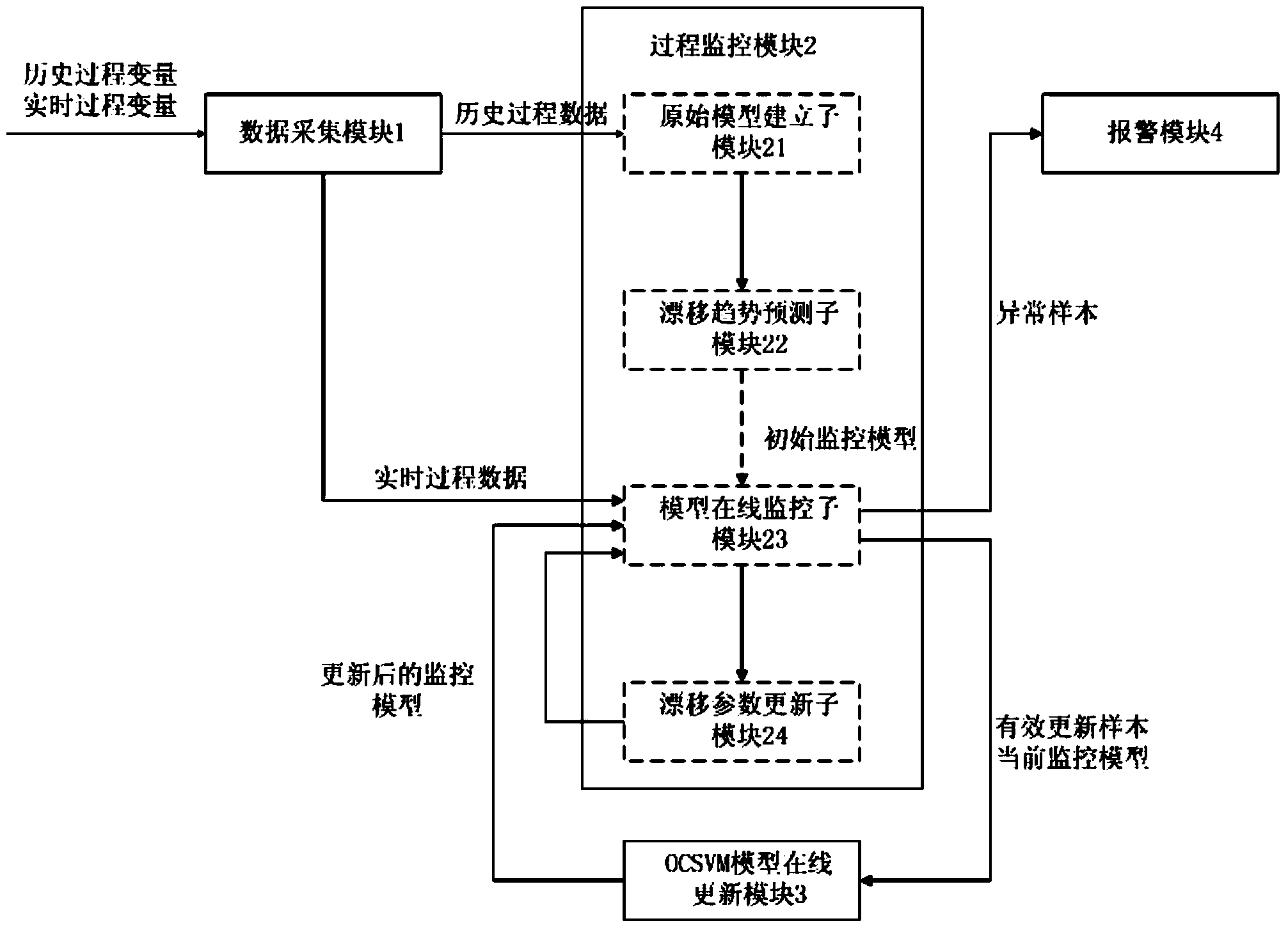

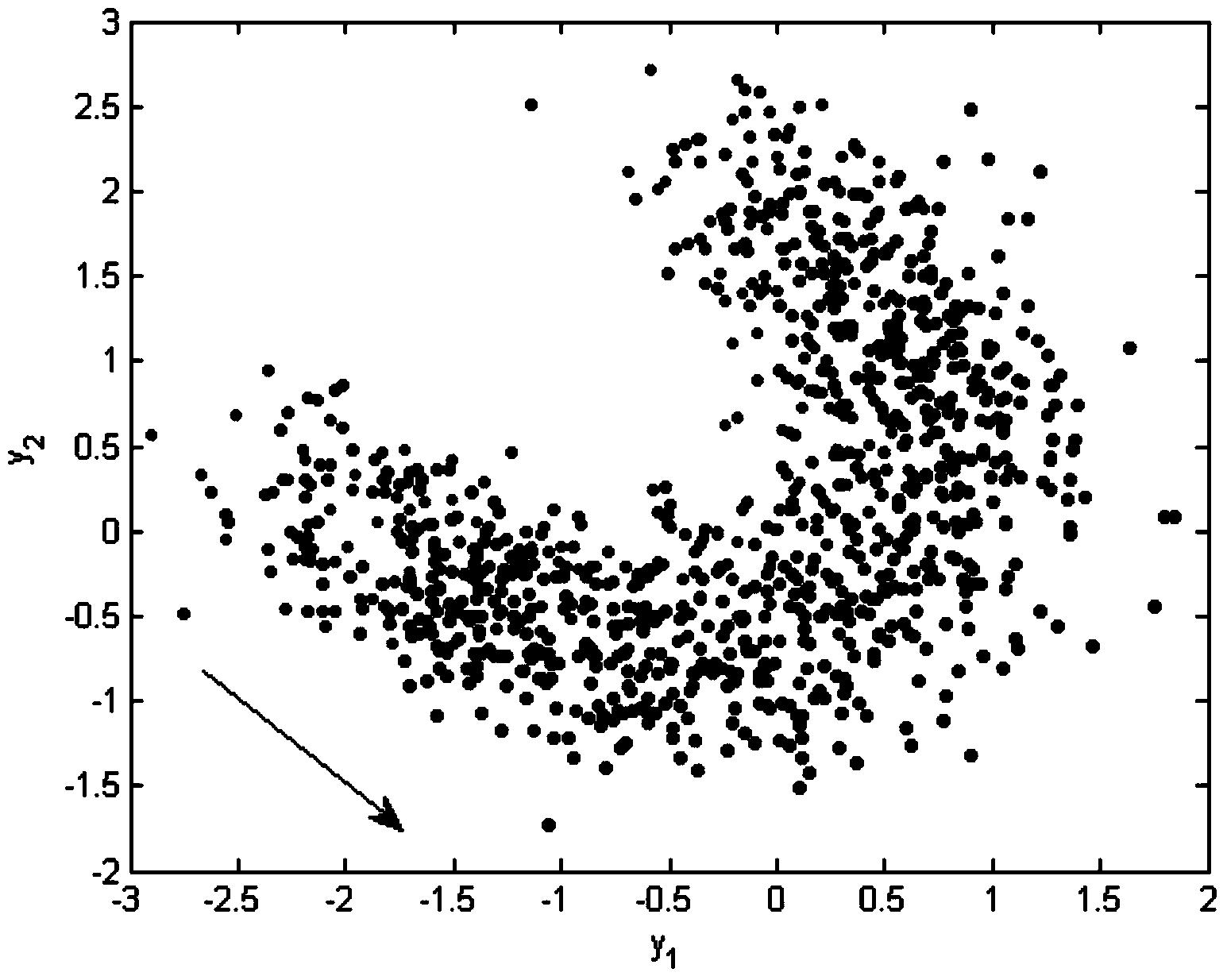

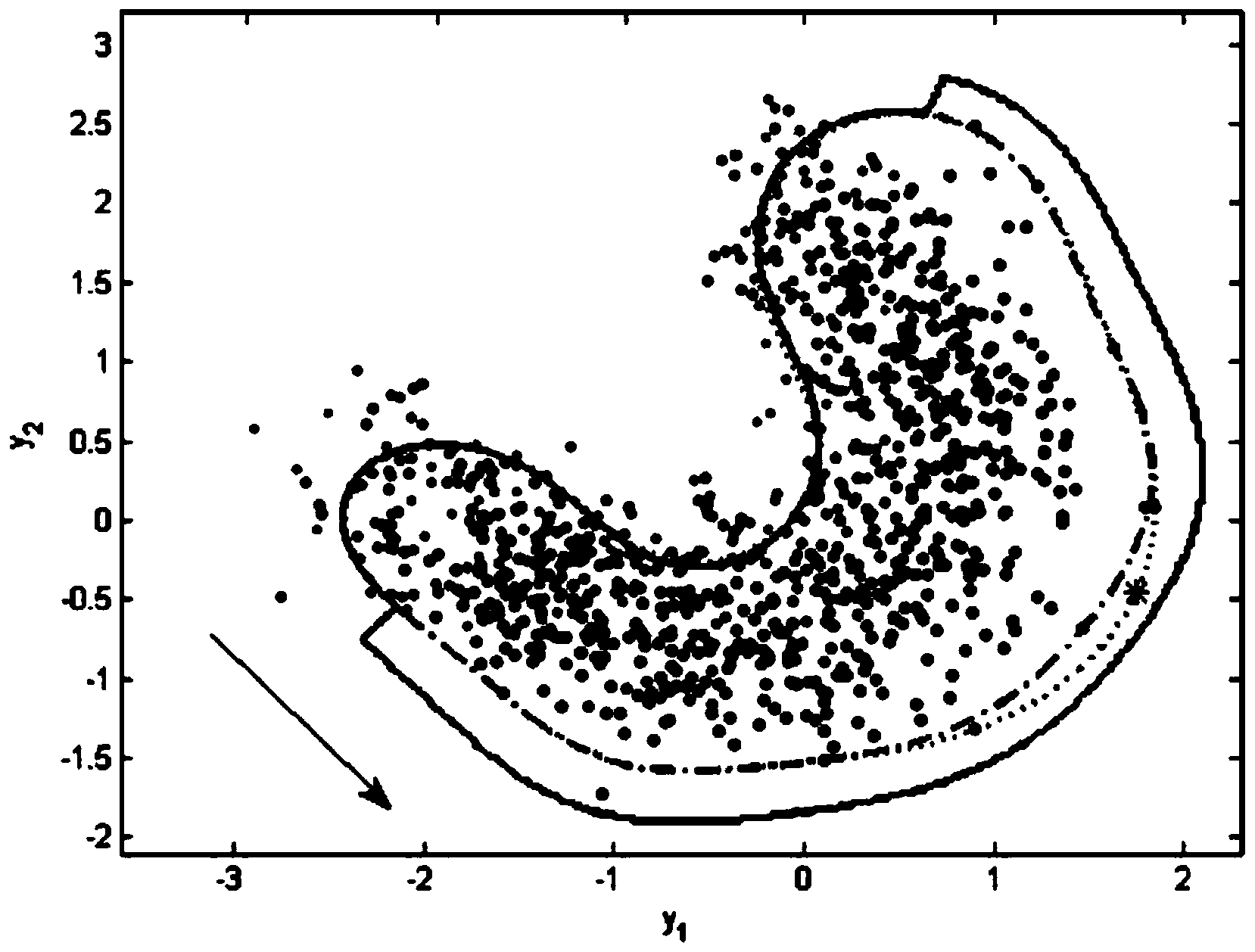

[0063] Example: such as figure 2 As shown, the data acquisition module 1 collects 1001 process variables representing the characteristics of the normal production process, and digitizes them into historical process data and real-time process data. These 1001 data are represented by 1001 solid circles in the Cartesian coordinate system, each A solid circle represents a two-dimensional data x i =(y 1 (i),y 2 (i)) T (where, i=1,2,…,1001), from the distribution of solid circles, it can be seen that the generation process is along the figure 2 The direction of the middle arrow has a slow drift trend. According to the time sequence of data collection, the first 1000 data are regarded as historical process data, and the 1001st data are regarded as real-time process data. The process of monitoring the above-mentioned certain production process by adopting the self-adaptive monitoring method of the production process of the present invention specifically includes the following s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com