A filter group for fluids

A fluid filter and filter group technology, which is applied in the fields of dispersed particle filtration, gas treatment, chemical instruments and methods, etc., can solve problems such as the ineffective utilization of tubular filter membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

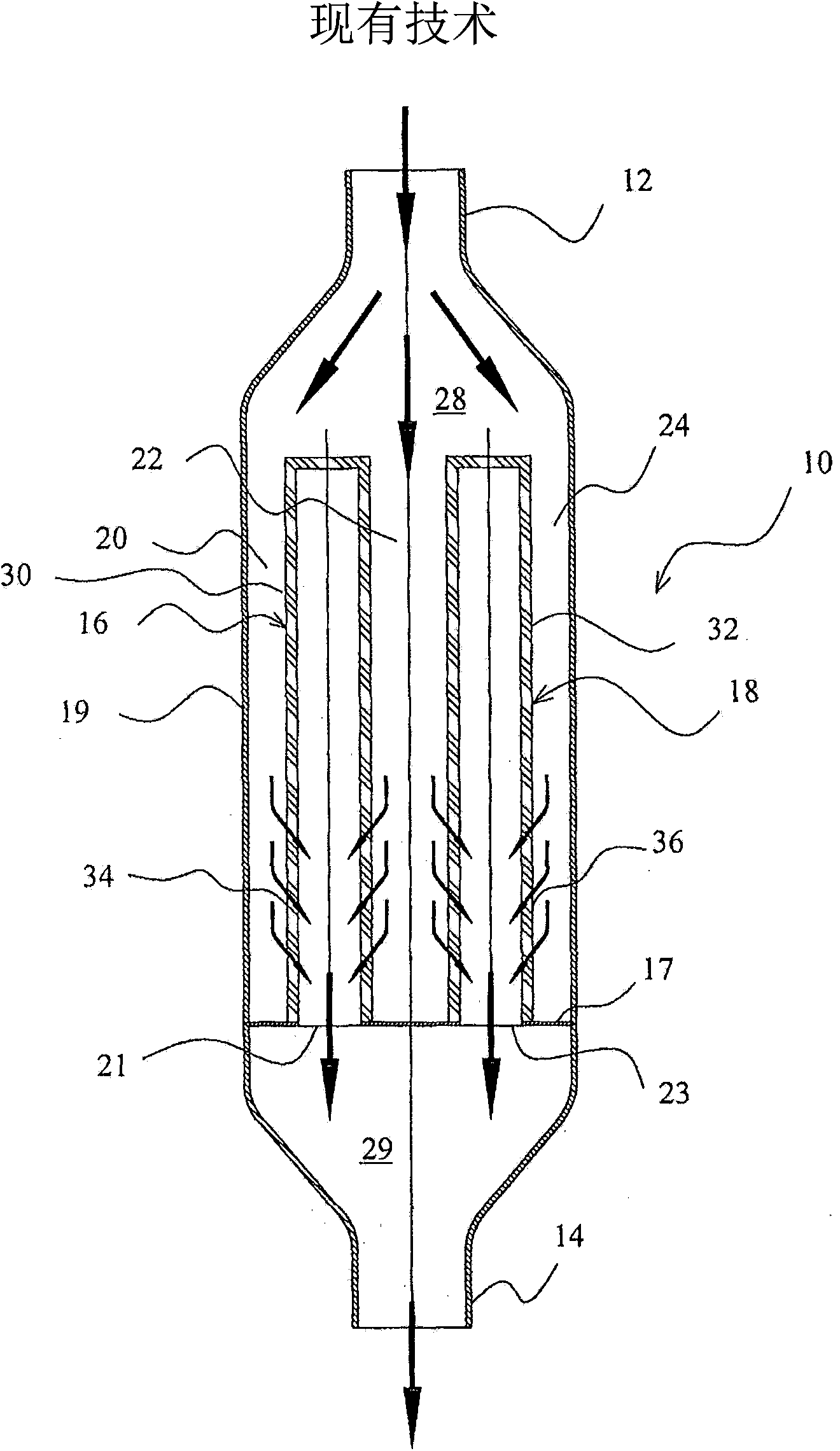

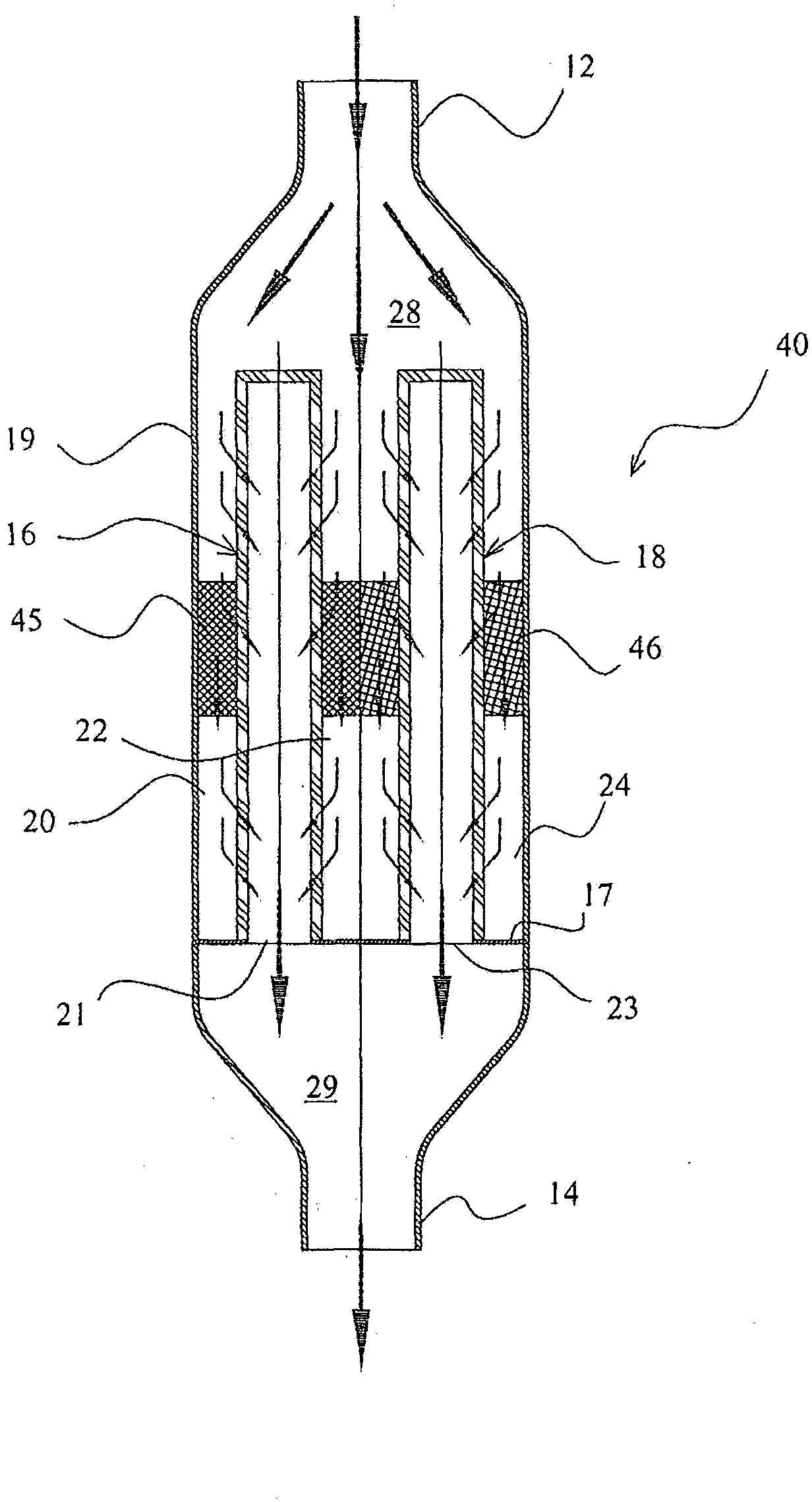

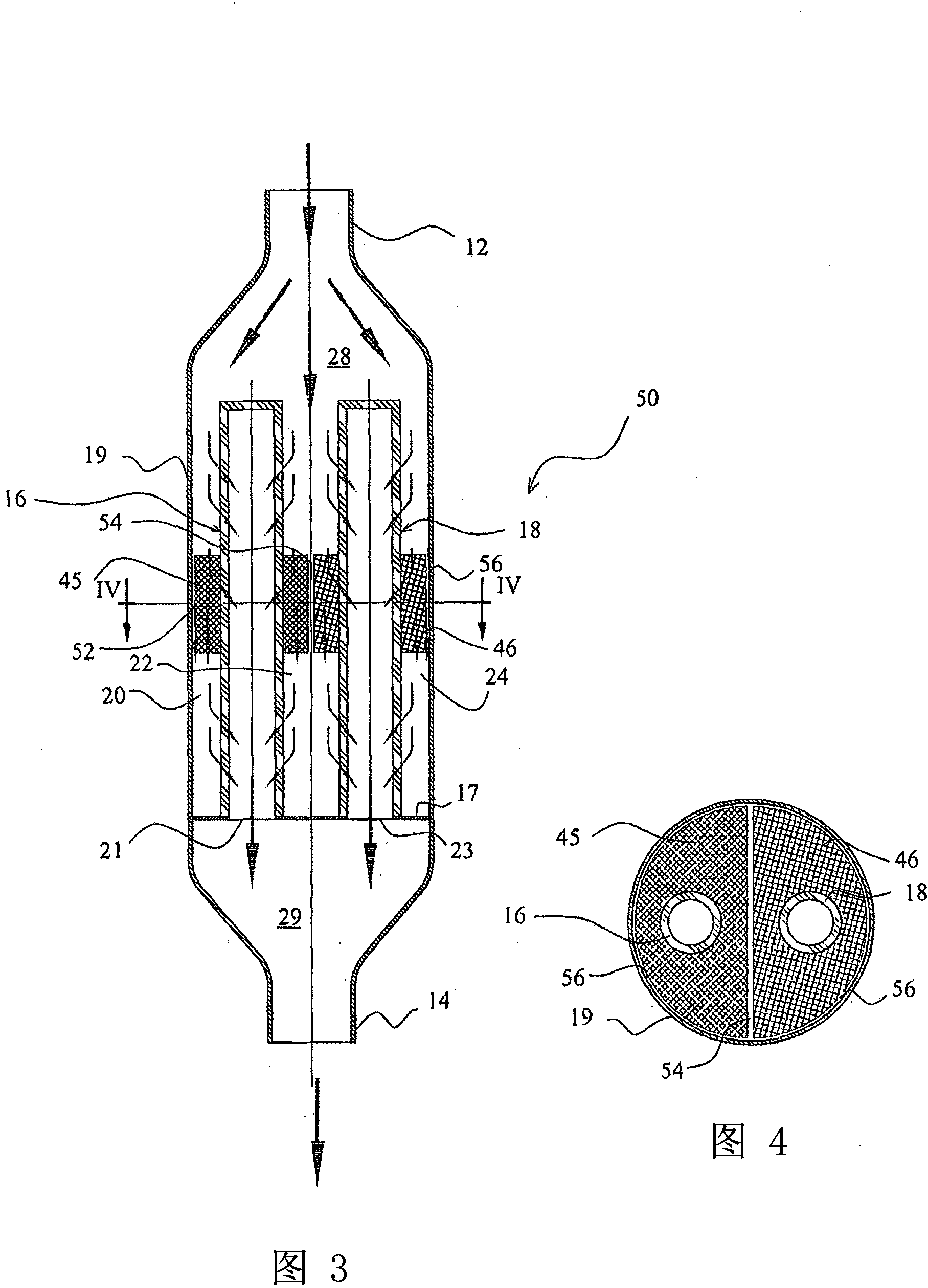

[0031] figure 2 An axial flow fluid filter 40 is shown comprising a generally tubular housing 19 providing an inlet conduit 12 for fluid to be filtered and an outlet conduit 14 for filtered fluid.

[0032] A perforated plate (perforated at 21 and 23) is arranged inside the housing 19, on which there are tubular filter membranes 16, 18 which extend parallel to the axis of the housing 19 and which The internal volume of the body is divided into two chambers 28, 29, of which the first chamber 28 communicates with the inlet conduit 12 for the fluid to be filtered and the second chamber 29 communicates with the outlet conduit 14 for the filtered fluid.

[0033] The fluid to be filtered thus enters the volumes 20, 22, 24 of the first chamber 28 which pass the fluid through the filter membrane. In one embodiment of the invention, the axial flow filter 40 includes pressure distributors 45 , 46 inside the chamber 28 .

[0034] In more detail, a pressure distributor 45, 46 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com