Two-way active rolling type stainless-steel spiral air pipe machine

A rolling type, stainless steel technology, applied in the field of mechanical sheet metal, can solve the problems of the occlusal edge not embedded in the bottom, the occlusal seam, and the shape of the air duct, etc. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

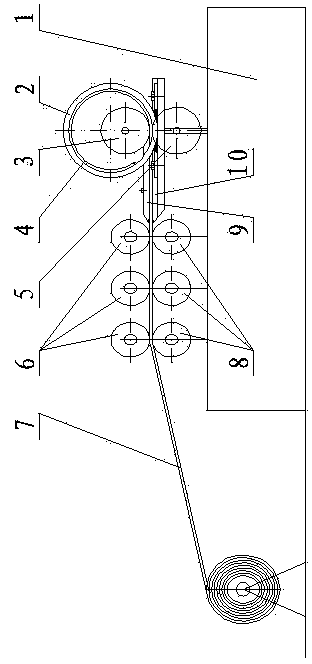

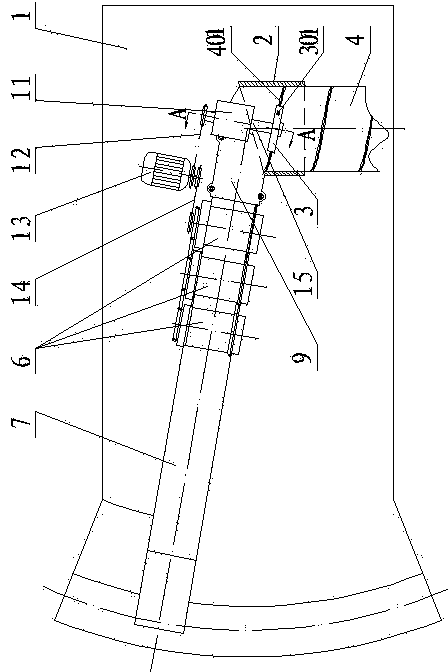

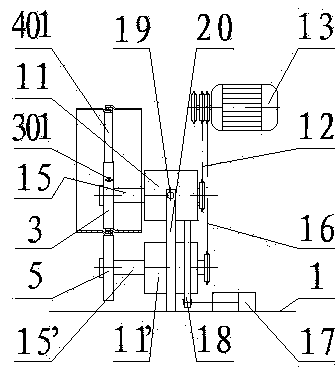

[0014] as attached figure 1 , 2 , 3, shown in 4, the present invention comprises frame 1, pulling jaw, upper pressing plate 9, lower pressing plate 10, fixed band mold 2 and rolling device, pulling jaw is by three pairs of upper and lower pressure rollers 6 and Composed of 8, the distances are arranged on the working table of the frame 1; the stainless steel belt 7 is clamped and pulled by three pairs of upper and lower pressure rollers 6 and 8, and the two sides are bent into occlusal edges at the same time; the upper and lower pressure plates 9 and 10 Set at the rear of the upper and lower pressure rollers 6 and 8, the stainless steel belt 7 passes between the upper and lower pressure plates 9 and 10; the fixed belt mold 2 is in the shape of a sleeve, one end of the sleeve is a plane, and the other end is a helical surface, It is arranged at the outlets of the upper and lower platens 9 and 10, and the axis line has a set angle with the direction of travel of the stainless s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com