Opposite punching type cutting knife base

A cutter seat and hedging technology, which is applied in the field of stamping devices, can solve the problems of large structure, cumbersome operation, and single function, and achieve the effects of broad market space, simple implementation, and simple manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

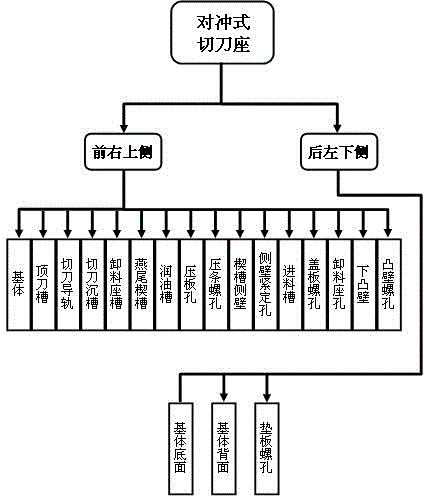

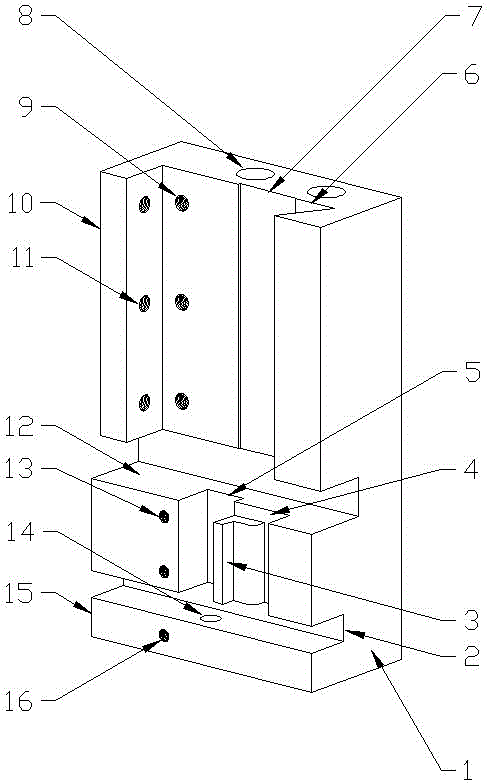

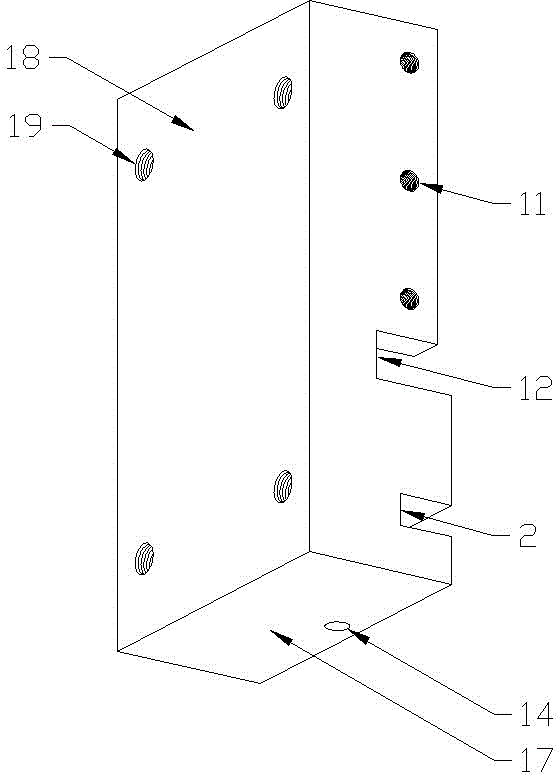

[0030] As a technical proposal for product manufacturing, the present invention can make the proposal concretely implemented through the organic combination of corresponding organizational structures. The product organization structure of an embodiment of the present invention is as follows: figure 1 shown.

[0031] figure 1 Among them, the product is composed of two modules on the front right upper side and the rear left lower side. Among them, the front upper right module includes the base body, the top knife groove, the cutter guide rail, the cutter sinker groove, the discharge seat groove, the dovetail wedge groove, the lubricating groove, Pressure plate hole, bead screw hole, wedge groove side wall, side wall fastening hole, feeding trough, cover plate screw hole, discharge seat hole, lower convex wall, convex wall screw hole sixteen components, the rear left lower side module It includes three components: the bottom surface of the base body, the back side of the base b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com