Machining process for square plate shell

A processing technology, square shell technology, applied in the field of square shell processing technology, can solve the problem that the overall shape of the square shell does not meet the requirements, the hole precision of the square shell is not enough, the strength of the square shell is not enough, etc. problems, to achieve the effect of reducing material consumption, small margin, and convenient steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

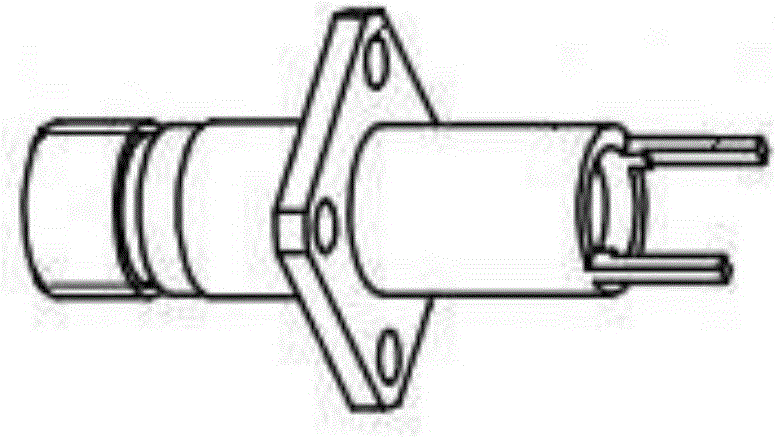

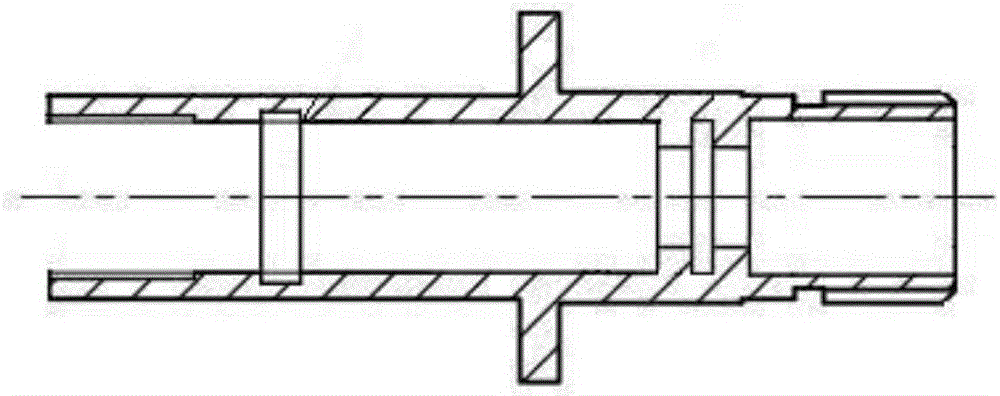

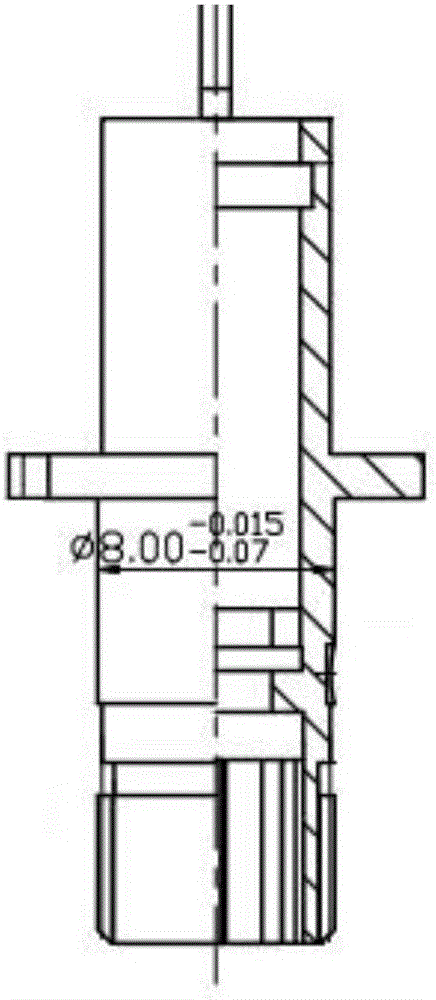

[0023] According to attached Figures 1 to 4 As shown, the embodiment of the present invention includes: a processing technology of a square plate shell, and the steps of the deployment method include:

[0024] First, the outer diameter of the front end of the rough car: clamp the blank on the machine tool according to the size requirements of the part, and perform outer diameter turning on one end. The outer diameter is 8mm, and the length of the rough car is 15mm;

[0025] Second, drill the central axis hole: drill a 3.8mm through hole on the central axis of the blank;

[0026] Third, the inner diameter of the front end of the rough car: according to the position of the center shaft hole, rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com