A method for forming a square plate shell blank and its supporting forming die

A square plate shell and forming die technology, applied in metal extrusion die and other directions, can solve the problems of waste material processing, reduce mechanical properties, difficulties, etc., to reduce material consumption, improve formability, and increase work hardening strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

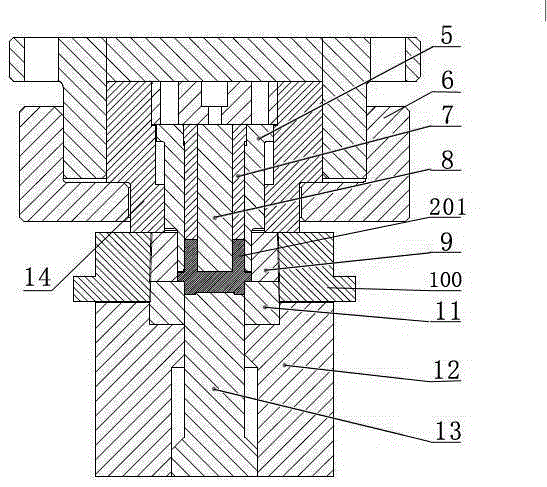

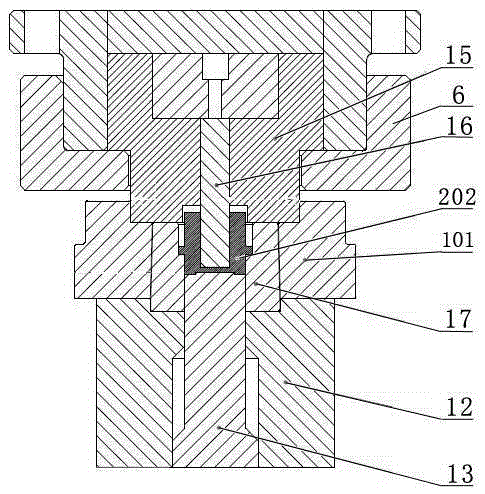

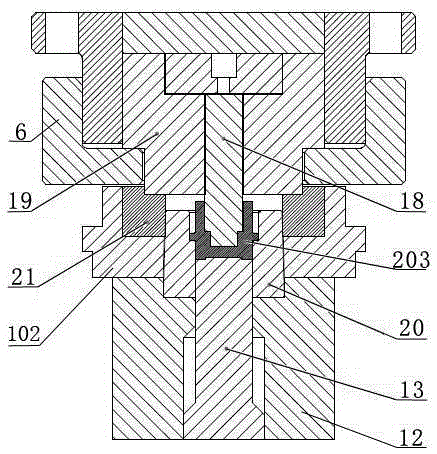

Image

Examples

Embodiment Construction

[0026] The square shell blank forming method includes the following steps: 1 high-speed band saw blanking and deburring; 2 blank annealing and softening treatment: electric heating furnace, 400-430 ℃ heat preservation for 1-2 hours, cooling with the furnace; 3 blank surface treatment : Coated with lubricating oil or zinc stearate powder; 4. The outer square plate and shallow inner hole are formed by the first-order occlusion extrusion; 5. The second-order reverse extrusion is formed into a square inner hole; 7 Extrusion rough solution aging treatment, subsequent numerical control processing. Specific steps are as follows:

[0027] Step 1. Select an aluminum alloy bar material with a slightly smaller outer diameter according to the target size of the square shell blank, and after cutting the material with a high-speed band saw, manually remove the end surface burrs of the sawed material to obtain a sawed blank;

[0028] Step 2. Soften the sawn blank in step 1, that is, place t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com