Active inhibition device and method for band-saw blade vibration on the basis of master vibration modal prediction

A technology of active suppression and band saw blades, which is applied to the accessories of sawing machines, manufacturing tools, metal sawing equipment, etc., can solve the problems of complex structure and high precision requirements of devices, and achieve the effect of high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings.

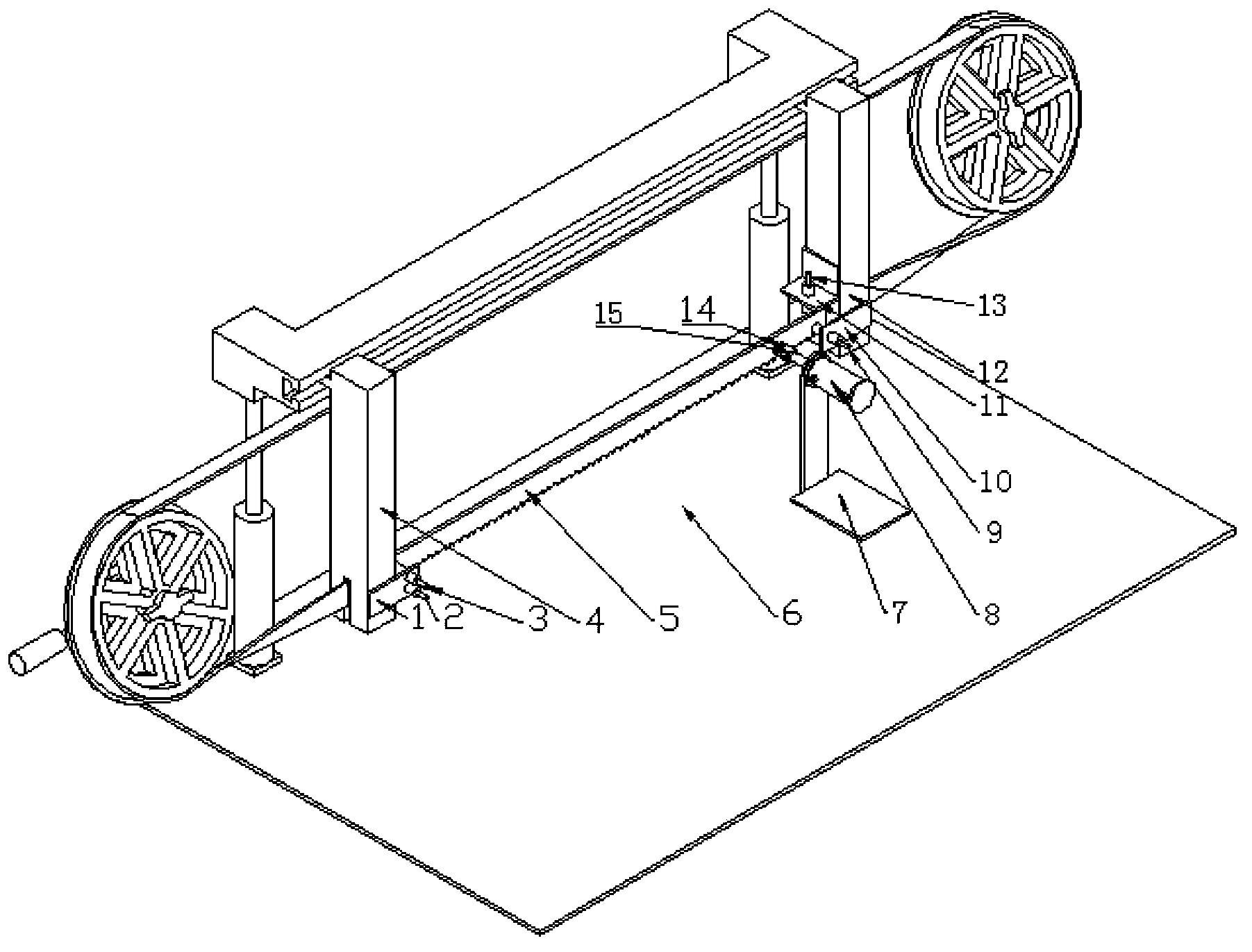

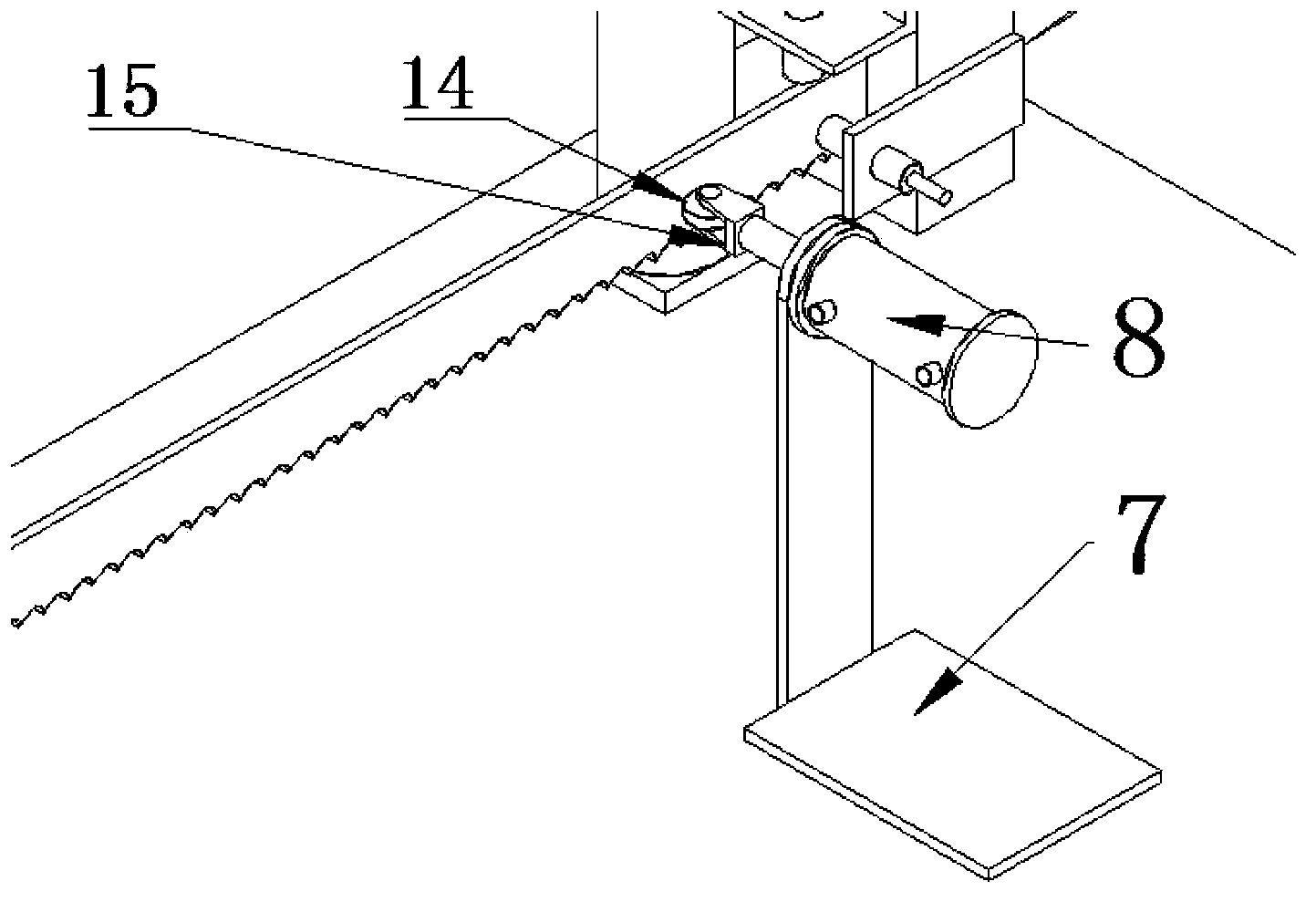

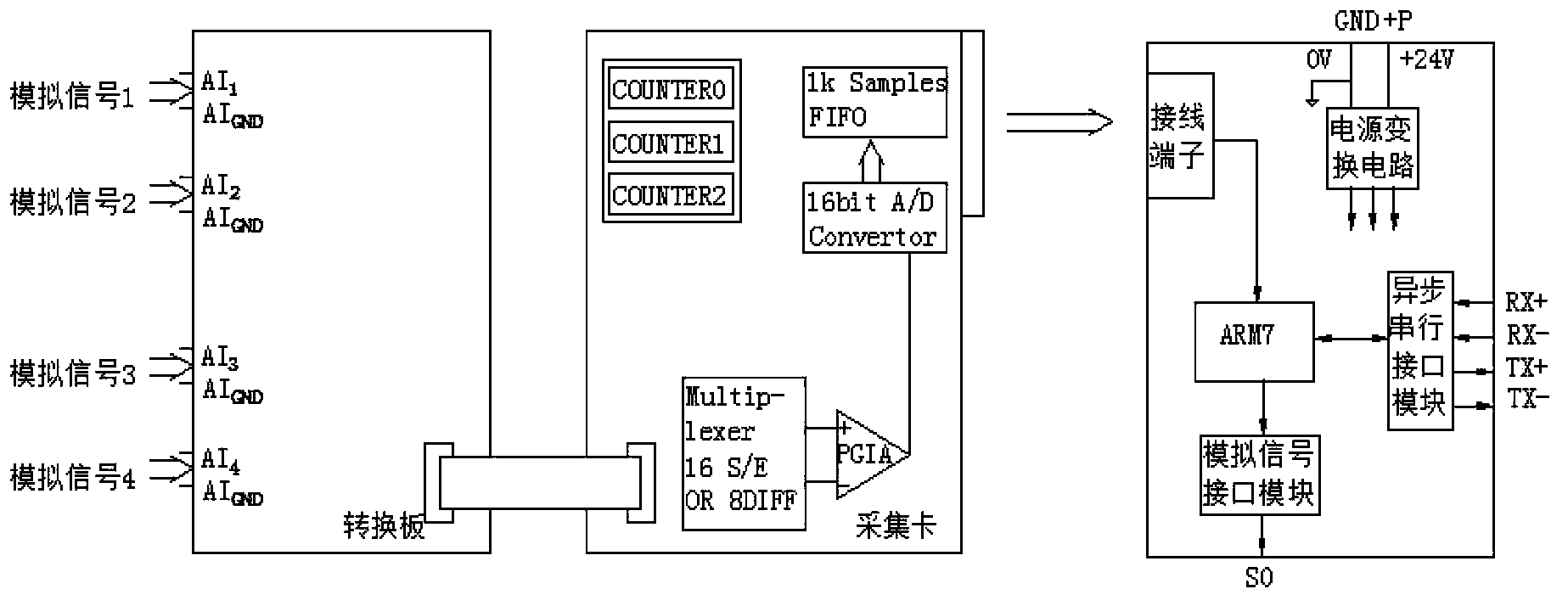

[0055] like figure 1 , figure 2 As shown, a band saw blade vibration active suppression device based on main vibration mode prediction includes a first eddy current sensor 2, a second eddy current sensor 3, a third eddy current sensor 9, a fourth eddy current sensor 13, a first sensor Bracket 1, second mounting bracket 10, third mounting bracket 11, a thin-walled hydraulic cylinder 8, a piston rod earring 15, a roller 14 and a hydraulic cylinder mounting frame 7.

[0056] The first eddy current sensor 2 and the second eddy current sensor 3 are installed on the first guide post 4 of the metal band sawing machine through the first sensor bracket 1, and the first eddy current sensor 2 and the second eddy current sensor 3 are in the In the same vertical plane and facing the side of the band saw blade 5, the third eddy current sensor 9 and the fourth eddy current sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com