A mechanical coiling device for helical slices of helical ground piles

A technology of helical ground piles and helical sheets, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult quality assurance, high production costs, and difficulty in ensuring tight fit between the helical sheets and ground piles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

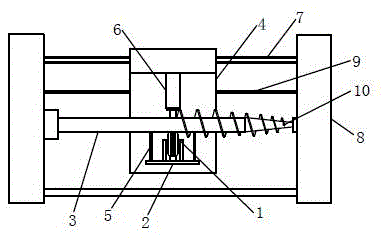

[0010] Depend on figure 1 It can be known from the illustrated embodiment that the screw ground pile clamping and rotating mechanism is included, and the spiral ground pile clamping and rotating mechanism is provided with a power driving device, and the spiral ground pile clamped by the spiral ground pile clamping and rotating mechanism is mounted on the side There is a helical piece clamping runner 1, and a helical piece positioning and clamping groove is arranged in the middle of the helical piece clamping runner 1. The helical piece clamping runner 1 is rotatably connected with the clamping runner bracket 2, and the clamping runner bracket 2. It is connected with the piston type actuator 6 used to make the helical plate clamping runner 1 closely contact with the spiral ground pile rod 3. The piston type actuator 6 is fixed on the horizontal translation sliding mechanism, and the sliding track of the horizontal translation sliding mechanism Parallel to the axis of the spiral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com