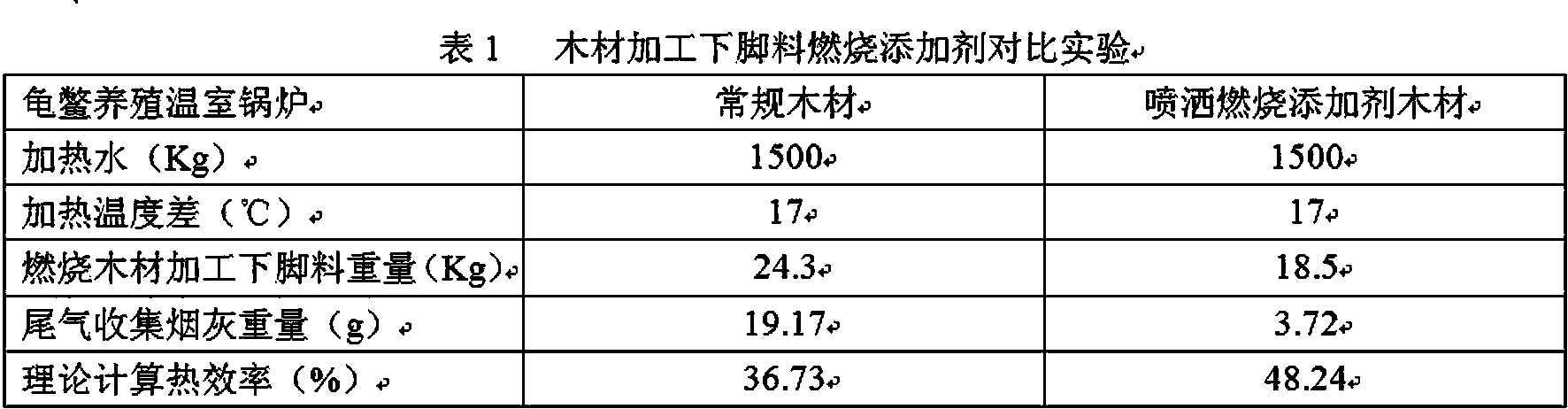

Wood processing offal additive for testudinate greenhouse cultivation combustion and using method thereof

An additive and wood technology, applied in wood processing equipment, impregnated wood, wood impregnation, etc., can solve the problems of inability to improve wood combustion efficiency, reduce black smoke, reduce emission concentration and blackness, and prolong boiler life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A wood processing scrap additive for burning turtles in greenhouses, consisting of the following components: Fe 2 o 3, MgO, KCl , NaCl and KMnO 4 , the parts by weight of each component are as follows: Fe 2 o 3 9~10, MgO 55~60, KCl 8~10, NaCl 16~18, KMnO 4 9~12.

[0034] The use method of above-mentioned additive, comprises the following steps:

[0035] ①Adopt the above-mentioned additives as claimed in the claims, place in water and stir, so that soluble components are dissolved in water, and insoluble components are suspended in water to form a water dispersant. allow;

[0036] 2. Spray the water dispersant evenly on the surface of the wood processing scrap, so that the soluble components in the water dispersant are completely or partially absorbed into the internal tissue of the wood processing scrap, so that the water in the water dispersant evaporate in whole or in part, and finally reach

[0037] The soluble component is contained in the tissue of the tr...

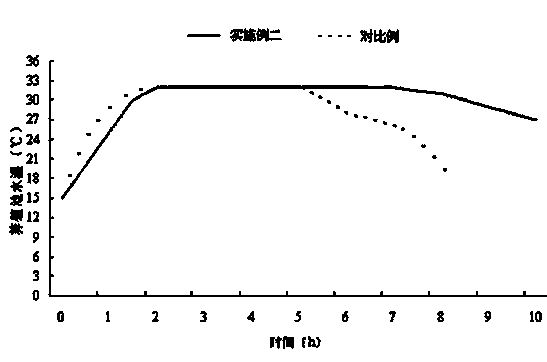

Embodiment 2

[0045] A wood processing scrap additive for burning turtles in greenhouses, consisting of the following components: Fe 2 o 3 , MgO, KCl , NaCl and KMnO 4 , the parts by weight of each component are as follows: Fe 2 o 3 9. MgO 56, KCl 9, NaCl 17, KMnO 4 10.

[0046] The use method of above-mentioned additive, comprises the following steps:

[0047] ①Adopt the above-mentioned additives as claimed in the claims, place in water and stir, so that soluble components are dissolved in water, and insoluble components are suspended in water to form a water dispersant. allow;

[0048] 2. Spray the water dispersant evenly on the surface of the wood processing scrap, so that the soluble components in the water dispersant are completely or partially absorbed into the internal tissue of the wood processing scrap, so that the water in the water dispersant evaporate in whole or in part, and finally reach

[0049] The soluble component is contained in the tissue of the trimmings from ...

Embodiment 3

[0057] A wood processing scrap additive for burning turtles in greenhouses, characterized in that it consists of the following components: Fe 2 o 3 , MgO, KCl , NaCl and KMnO 4 , the parts by weight of each component are as follows: Fe 2 o 3 10. MgO 58, KCl 8, NaCl 17, KMnO 4 10.

[0058] The use method of above-mentioned additive, comprises the following steps:

[0059] ①Adopt the above-mentioned additives as claimed in the claims, place in water and stir, so that soluble components are dissolved in water, and insoluble components are suspended in water to form a water dispersant. allow;

[0060] 2. Spray the water dispersant evenly on the surface of the wood processing scrap, so that the soluble components in the water dispersant are completely or partially absorbed into the internal tissue of the wood processing scrap, so that the water in the water dispersant evaporate in whole or in part, and finally reach

[0061] The soluble component is contained in the tissu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com