A large-format printer with a winding frame of a hot air blowing device

A printer, large format technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

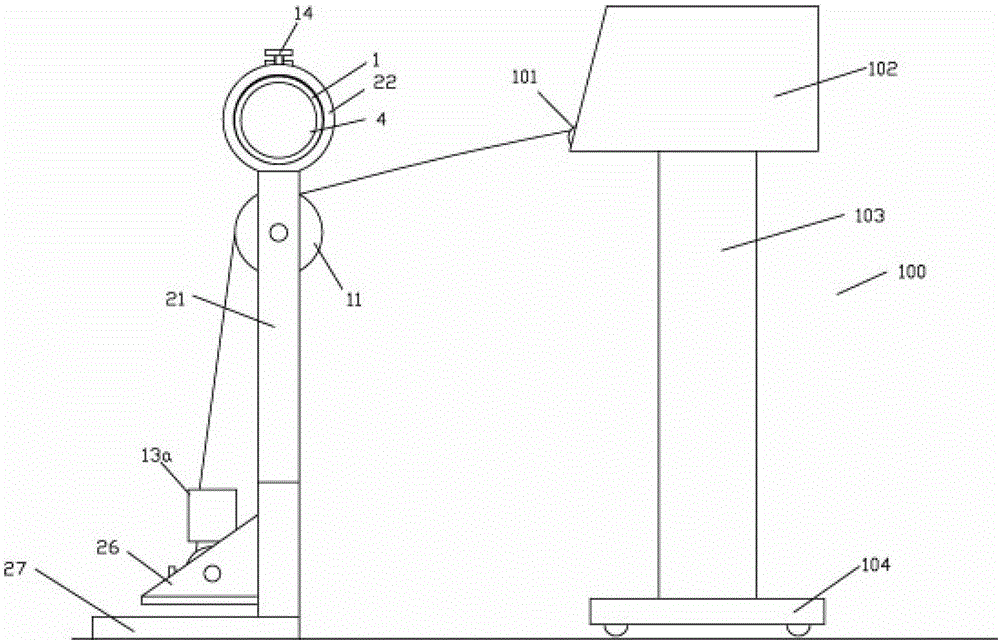

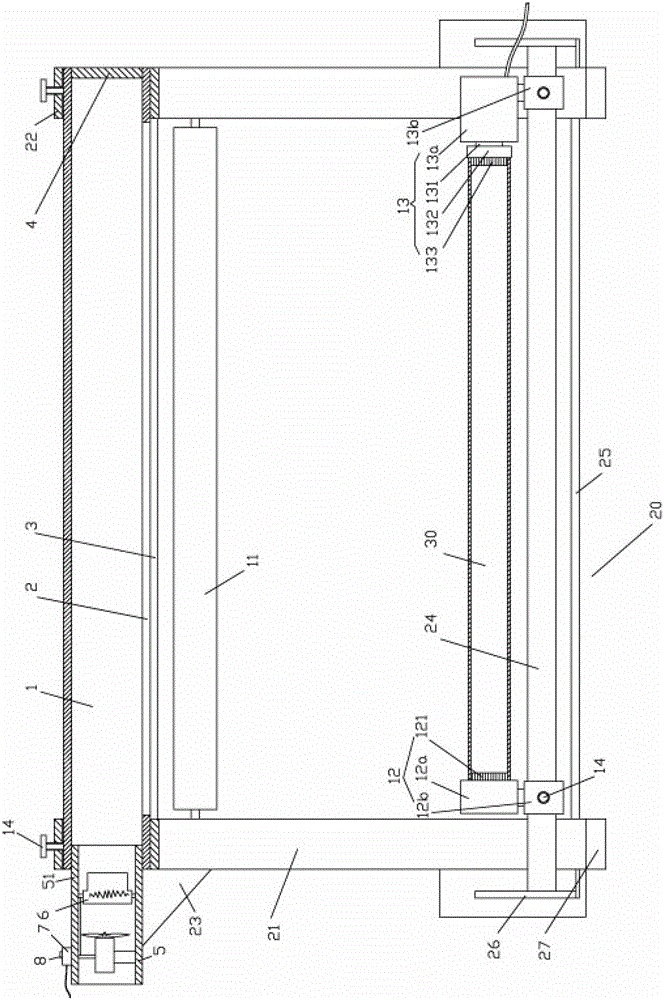

[0023] Examples, see e.g. Figures 1 to 5 As shown, a large-format printer with a winding frame of a hot blowing device includes a large-format printer 100, the large-format printer 100 is behind the frame body 20, and the lead-out roller 101 of the large-format printer 100 faces the guide on the frame body 20. Roller 11, the large-format printer 100 is composed of a main body 102, two support plates 103 fixed on the bottom surface of the main body 102, and a bottom rolling frame 104 fixed to the lower ends of the two support plates 103;

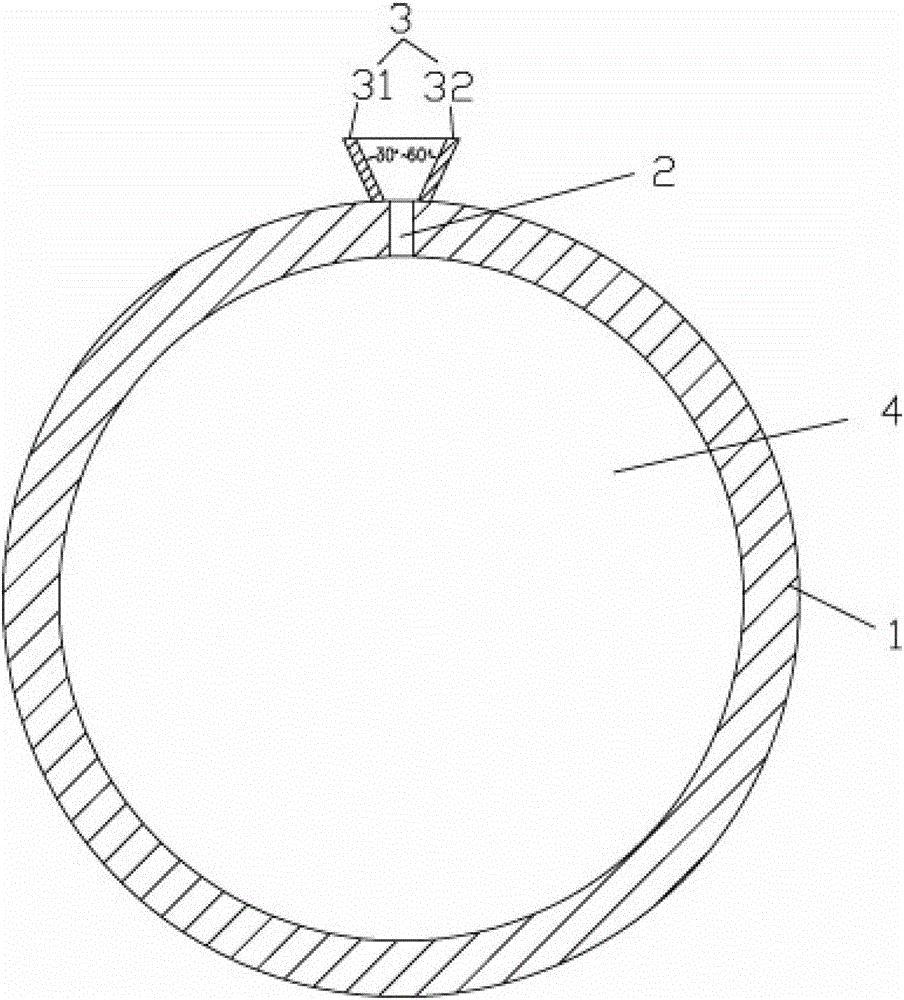

[0024] Guide rollers 11 are hinged between the two support rods 21 of the frame body 20, and a support sleeve 22 is fixed on the top of the two support rods 21. The hot blowing device is arranged on the support sleeve 22, and the air outlet of the hot blowing device The air outlet of 3 faces the guide roller 11;

[0025] The bottom of the frame body 20 is fixed with a slide bar 24, the roller support frame 12 and the drive frame 13 are all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com