Full-automatic battery label sticking machine

A label sticking and fully automatic technology, applied in the direction of labeling, labeling, labeling machines, etc., can solve the problems of complex action process and overall structure, complex mechanical structure, and complex operation process, so as to shorten the action cycle, simplify the mechanical structure, The effect of accurate pasting position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

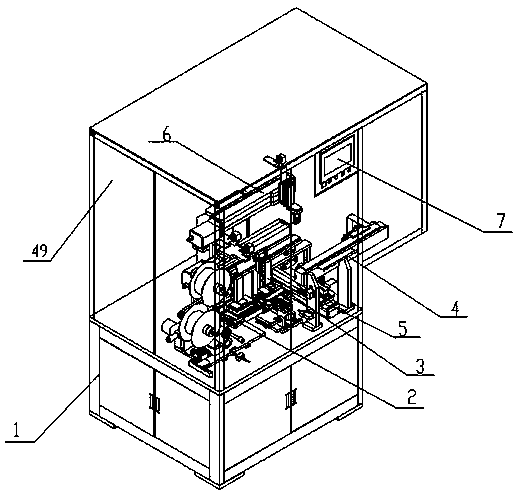

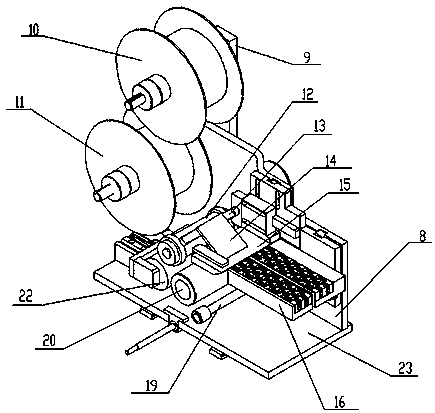

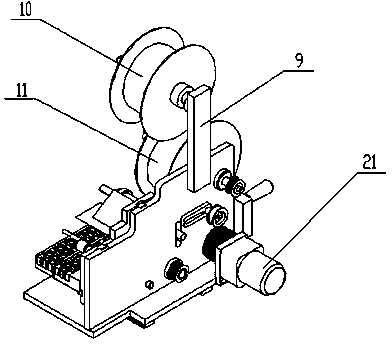

[0030] Such as Figure 1-9 as shown,

[0031] The invention provides a fully automatic battery label sticking machine, comprising a frame 1, a label and backing paper separation device 2 located on the frame 1, a label finishing device 3, a battery picking device 4, a battery longitudinal moving device 5 and a battery return Device 6, the label pasting machine is also connected with a numerical control display device 7, wherein:

[0032] The label and back paper separation device 2 includes a vertical plate 8, the upper left of the vertical plate 8 is connected to the label paper tray 10 through the first connecting rod 9, and the label paper tray 10 is connected to the first connecting rod The upper end shaft of 9 is connected, the lower left side of the label paper tray 10 is provided with a backing paper tray 11, the backing paper tray 11 is connected with the vertical plate 8 shafts, and the lower right side of the backing paper tray 11 is provided with an adjusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com