Conveyor with adjustable height

A conveyor and height technology, applied in the field of conveyors, can solve problems such as the inability to adjust the height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] This specific embodiment is only an explanation of the present invention, but not a limitation of the present invention. Any modification made by those skilled in the art after reading the description of the present invention will be protected by the patent law as long as it falls within the protection scope of the claims.

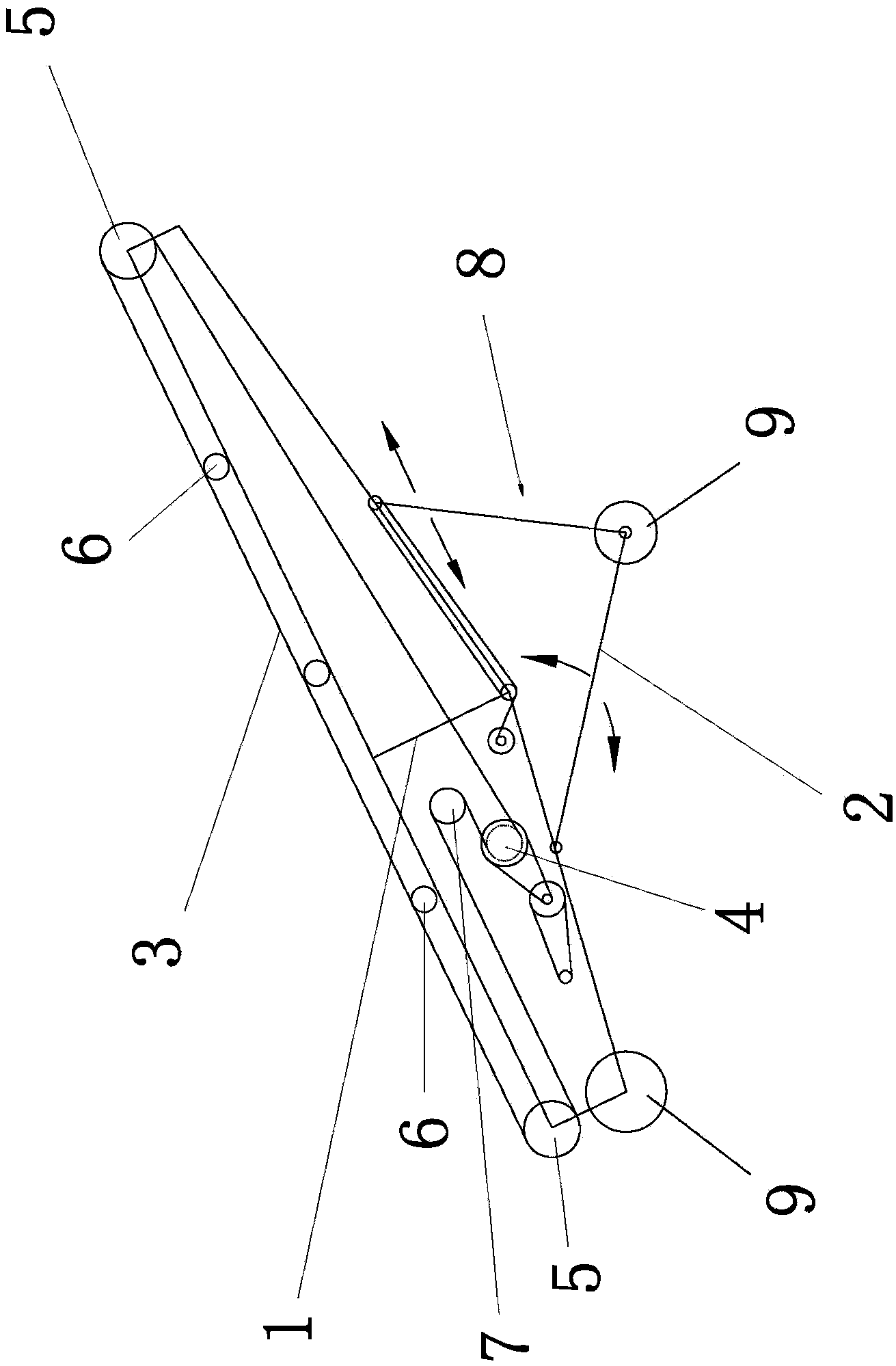

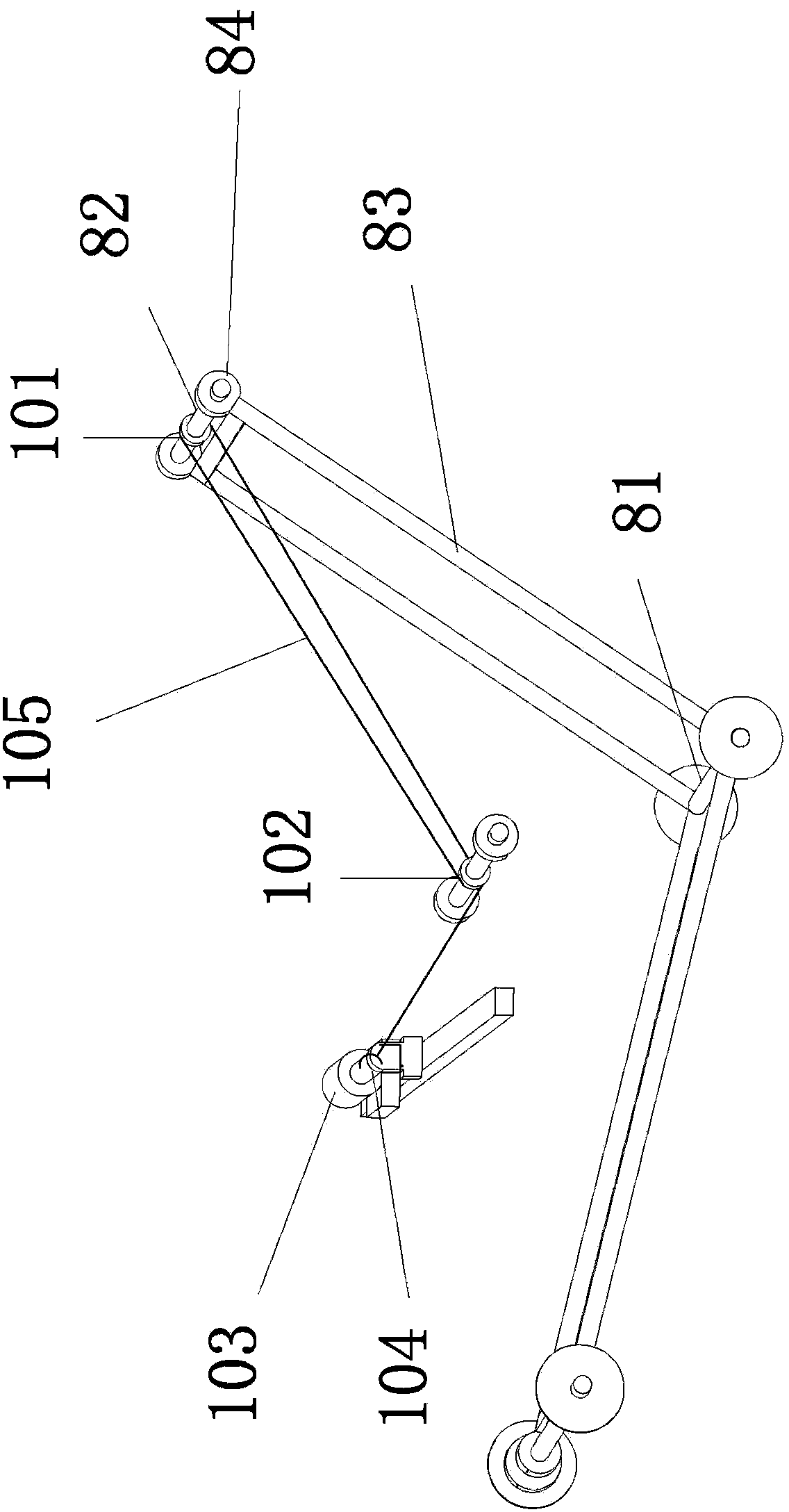

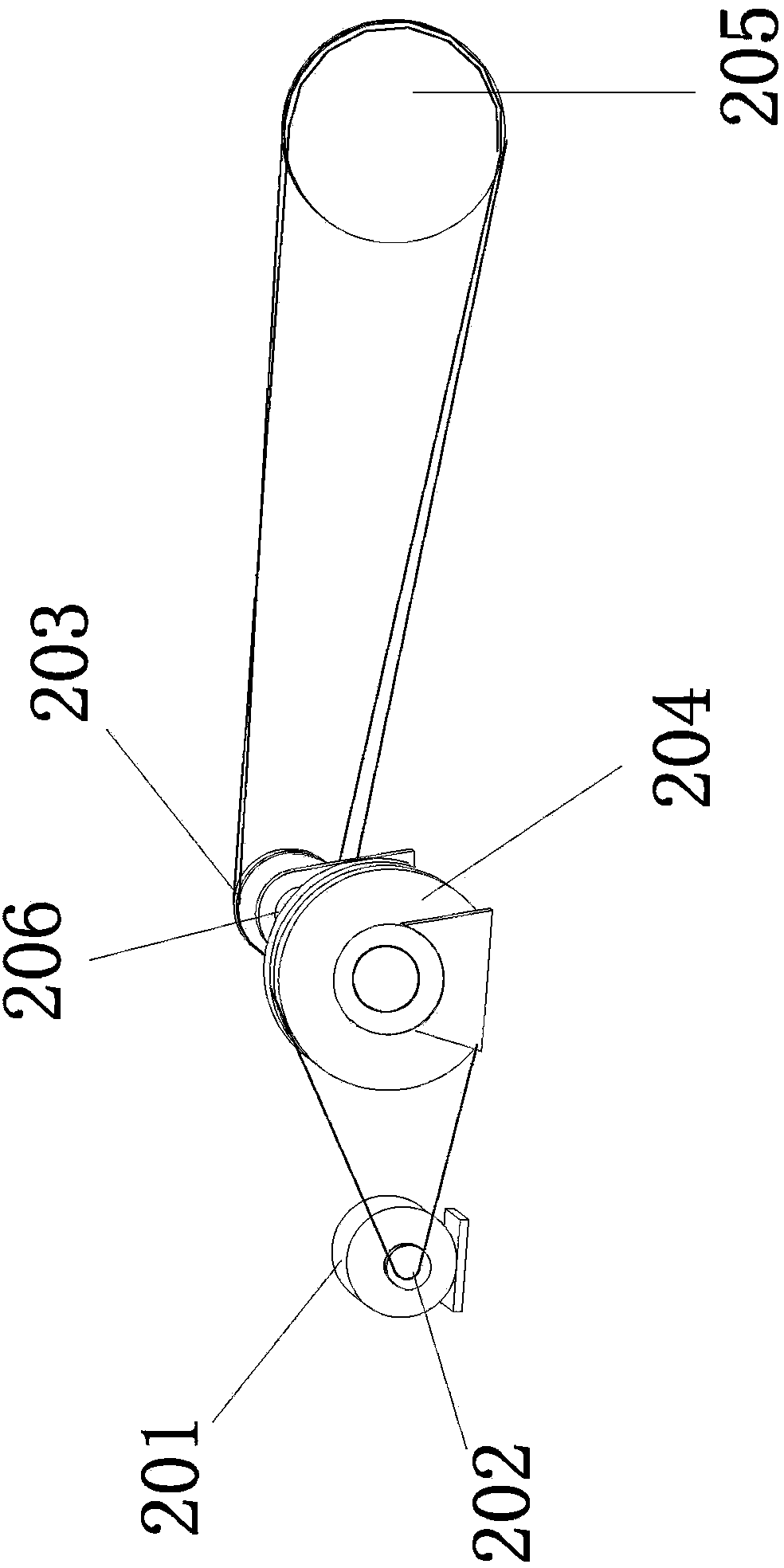

[0024] Such as Figure 1-3 As shown, a height-adjustable conveyor includes a conveyor frame 1 erected obliquely upward, a support frame 2 erected obliquely downward, a support frame 8, a conveyor belt 3, a power roller 4, a driven roller 5 and a support roller 6 , the support frame 8 includes a bottom cross bar 81, a support cross bar 82 and a vertical rod 83, the support cross bar 82 is rotatably connected with the vertical rod 83, the vertical rod 83 is rotatably connected with the bottom cross bar 81, and the support Supporting wheels 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com