PE (Poly Ethylene) preservative film and preparation method thereof

A fresh-keeping film and polyisobutylene technology, which is applied in the field of plastic packaging, can solve the problems of inability to penetrate the packaging contents well, low transparency, easy to disperse, etc. Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

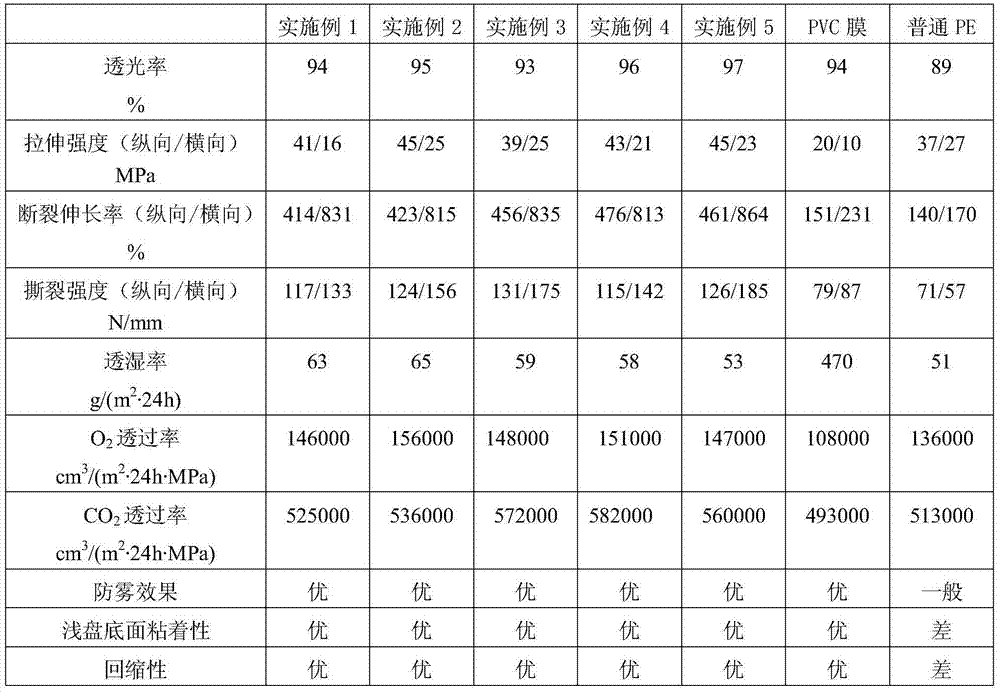

[0013] The used raw material formula of the PE cling film that embodiment 1 to 5 prepares

[0014]

[0015] Disperse LLDPE, polyisobutylene, TPEE elastomer, and ultra-low-density polyethylene in water first, then add talc powder, silicon dioxide, glycerol, sorbitol, Span40, and trimethylolpropane, and heat to 95°C. After stirring evenly, cool to 50-70°C to obtain a solution for casting film; cast the obtained solution on the steel belt of the casting production line through the die head, and then pass through the drying tunnel at 130-180°C for drying film forming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com