A kind of preparation method of fiber structure molybdenum copper composite material

A fiber structure and composite material technology, applied in the field of metallurgy, can solve the problems of reducing thermal conductivity and electrical conductivity of alloys, uneven pore distribution, small difference in specific gravity, etc., and achieves a high degree of densification, a large composition range, and a dense and uniform structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

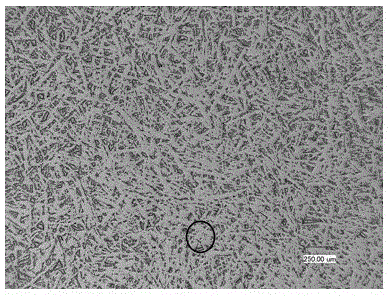

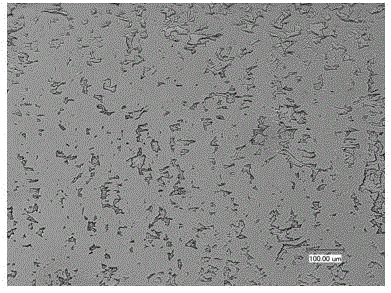

[0028] Take a fiber-structured molybdenum-copper composite material as an example, the composition and content of which are 80wt% molybdenum and 20wt% copper. The diameter of the molybdenum fiber is 20 μm, the purity is ≥99.9%, and the copper is T2 copper.

[0029] The preparation process comprises the following steps:

[0030] (1) The molybdenum fiber is laid and stacked to make a moderately fluffy two-dimensional fiber mat, and the porosity of the fiber mat is 80%;

[0031] (2) The fiber mat is molded and pressed to obtain a three-dimensional fiber preform, and the pressing pressure is controlled within the range of 20-50MPa. At this time, the porosity of the fiber preform is 23%~34%;

[0032] (3) Place the copper ingot and the molybdenum fiber preform together on the ZrO 2 In the sintering boat, copper is placed on the molybdenum fiber preform;

[0033] (4) Place the sintered boat in a vacuum environment, and keep the vacuum at 1×10 -3 Above Pa, the heating rate is 3~11...

Embodiment 2

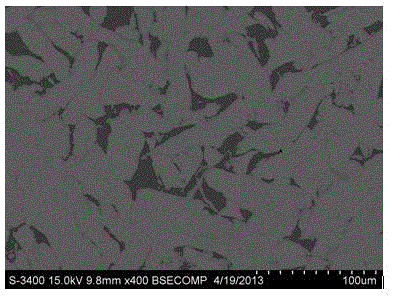

[0036] A fibrous structure molybdenum-copper composite material, taking the composition and content of molybdenum 85wt% and copper 15wt% as an example. The diameter of the molybdenum fiber is 30 μm, the purity is ≥99.9%, and the copper is T2 copper.

[0037] The preparation process comprises the following steps:

[0038] (1) The molybdenum fiber is laid and stacked to make a moderately fluffy two-dimensional fiber mat, and the porosity of the fiber mat is 75%;

[0039] (2) The fiber mat is molded and pressed to obtain a three-dimensional fiber preform, and the pressing pressure is controlled within the range of 50-80MPa. At this time, the porosity of the fiber preform is 15% to 22%;

[0040] (3) Place the copper ingot and the molybdenum fiber preform together on the ZrO 2 In the sintering boat, copper is placed on the molybdenum fiber preform;

[0041] (4) Place the sintered boat in a vacuum environment, and keep the vacuum at 1×10 -3 Above Pa, the heating rate is 3~11°C / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com