Control method used for spinning cake dewaterer

A control method and dehydrator technology, applied in electrical program control, program control in sequence/logic controller, liquid/gas/vapor removal by centrifugal force, etc., can solve the problem of poor reliability of travel switch, high equipment failure rate, maintenance The cost increase and other problems, to achieve the effect of accurate and reliable positioning, reduce the failure rate, and reduce the maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

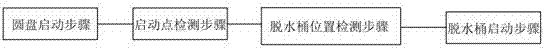

[0021] A control method for a silk cake dehydrator, comprising a disc starting step and a dehydration barrel starting step, and further comprising: a starting point detection step and a dehydration barrel position detection step performed before the dehydration barrel starting step, the starting point detection step In order to use the proximity switch I to detect the position of the starting point on the indexing plate, the position detection step of the dehydration bucket is to use the proximity switch II to detect the detection point corresponding to the dehydration barrel on the indexing plate after the proximity switch I detects the starting point. position; the starting step of the dehydration barrel is that after the detection point is detected by the proximity switch II, the controller starts the rotation of the dehydration barrel corresponding to the position of the detection point for dehydration.

[0022] In the present invention, the indexing plate is only provided ...

Embodiment 2

[0025] A control method for a silk cake dehydrator, comprising a disc starting step and a dehydration barrel starting step, and further comprising: a starting point detection step and a dehydration barrel position detection step performed before the dehydration barrel starting step, the starting point detection step In order to use the proximity switch I to detect the position of the starting point on the indexing plate, the position detection step of the dehydration bucket is to use the proximity switch II to detect the detection point corresponding to the dehydration barrel on the indexing plate after the proximity switch I detects the starting point. position; the starting step of the dehydration barrel is that after the detection point is detected by the proximity switch II, the controller starts the rotation of the dehydration barrel corresponding to the position of the detection point for dehydration.

[0026] In the present invention, the starting step of the disk is to ...

Embodiment 3

[0029] A control method for a silk cake dehydrator, comprising a disc starting step and a dehydration barrel starting step, and further comprising: a starting point detection step and a dehydration barrel position detection step performed before the dehydration barrel starting step, the starting point detection step In order to use the proximity switch I to detect the position of the starting point on the indexing plate, the position detection step of the dehydration bucket is to use the proximity switch II to detect the detection point corresponding to the dehydration barrel on the indexing plate after the proximity switch I detects the starting point. position; the starting step of the dehydration barrel is that after the detection point is detected by the proximity switch II, the controller starts the rotation of the dehydration barrel corresponding to the position of the detection point for dehydration.

[0030] In the present invention, the starting step of the disk is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com