Anti-ultraviolet fabric and its preparation method, anti-ultraviolet coating and its preparation method

An anti-ultraviolet and coating technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of poor anti-ultraviolet effect and long-lasting anti-ultraviolet effect, and achieve good anti-ultraviolet effect, long-lasting effect of anti-ultraviolet, good anti-ultraviolet effect and lasting effect. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

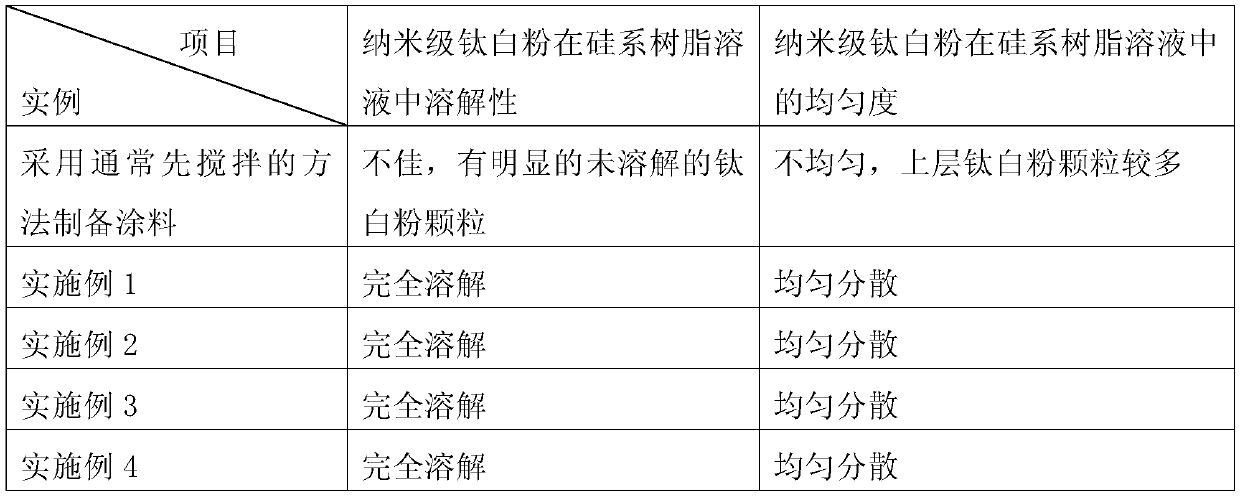

preparation Embodiment 1

[0027] In terms of parts by mass, weigh 50 parts of silicon-based resin, then add 10 parts of toluene, and finally add 40 parts of nano-sized titanium dioxide particles. After standing for 1-2 minutes, the nano-sized titanium dioxide particles After being completely dissolved in the solvent, start stirring again and stir evenly to obtain an anti-ultraviolet coating with a viscosity of 25000cps.

preparation Embodiment 2

[0029] In terms of parts by mass, weigh 65 parts of silicon-based resin, then add 10 parts of toluene, and finally add 15 parts of nano-scale titanium dioxide particles. After standing for 1-2 minutes, wait until the nano-scale titanium dioxide particles are completely After being dissolved in the solvent, start stirring again and stir evenly to obtain an anti-ultraviolet coating with a viscosity of 21000cps.

preparation Embodiment 3

[0031] In terms of parts by mass, weigh 55 parts of silicon-based resin, then add 15 parts of toluene, and finally add 25 parts of nano-scale titanium dioxide particles. After standing for 1-2 minutes, wait until the nano-scale titanium dioxide particles are completely After being dissolved in the solvent, start stirring again and stir evenly to obtain an anti-ultraviolet coating with a viscosity of 17000cps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com