A heat-sensitive color-changing rope and its manufacturing method

A production method and a heat-sensitive discoloration technology, which are applied in the rope field, can solve the problem that a thermometer should not be used to measure temperature, and achieve the effects of low cost, convenient and fast operation, and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

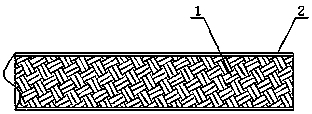

Image

Examples

Embodiment 1

[0026] 1) Preparation of temperature-indicating pigments: prepare temperature-indicating pigments with lead complex acid, filler, and nickel sulfate at a molar ratio of 1:1:0.1;

[0027] 2) Prepare the temperature-indicating paint: prepare the temperature-indicating paint with the temperature-indicating pigment and filler prepared in step 1), and 7% polyvinyl alcohol at a mass ratio of 1:0.5:6;

[0028] 3) Coating finishing: use the temperature-indicating paint prepared in step 2) to coat and finish the rope substrate, and finally dry it.

Embodiment 2

[0030] 1) Preparation of temperature-indicating pigments: prepare temperature-indicating pigments with lead complex acid, filler, and nickel sulfate at a molar ratio of 1:4:0.1;

[0031] 2) Prepare the temperature-indicating paint: prepare the temperature-indicating paint with the temperature-indicating pigment, filler, and 7% polyvinyl alcohol prepared in step 1) at a mass ratio of 1:1:6;

[0032] 3) Coating finishing: use the temperature-indicating paint prepared in step 2) to coat and finish the rope substrate, and finally dry it.

Embodiment 3

[0034] 1) Preparation of temperature-indicating pigments: prepare temperature-indicating pigments with lead complex acid, filler, and nickel sulfate at a molar ratio of 1:3:0.1;

[0035] 2) Prepare the temperature-indicating paint: prepare the temperature-indicating paint with the temperature-indicating pigment, filler, and 7% polyvinyl alcohol prepared in step 1) at a mass ratio of 1:0.8:6:;

[0036] 3) Coating finishing: use the temperature-indicating paint prepared in step 2) to coat and finish the rope substrate, and finally dry it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com