Thermochromic water-based ink for paper material and preparation method of thermochromic water-based ink

A temperature-sensitive discoloration and water-based ink technology, applied in the field of ink, can solve the problem of low adhesion, achieve excellent adhesion, extended application, and good effect of temperature-sensitive discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

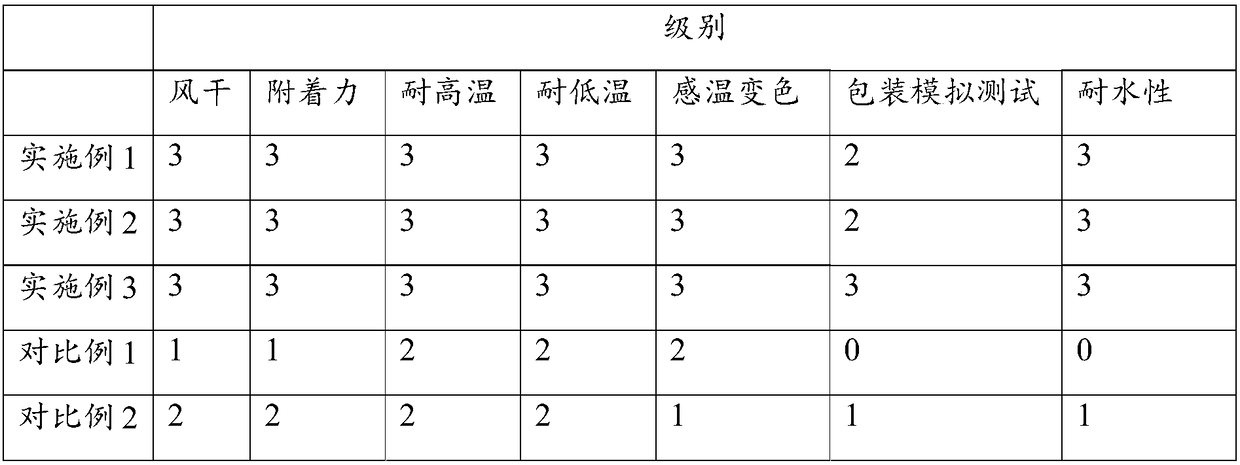

Examples

preparation example Construction

[0015] Embodiments of the present invention provide a method for preparing a thermochromic water-based ink for paper materials, comprising the following steps:

[0016] S1, 10-20 parts by weight of binder, 2-5 parts by weight of crosslinking agent, 50-70 parts by weight of solvent, 1-2 parts by weight of leveling agent, 0.5-1.5 parts by weight of wetting agent in Stir at 80-95°C for 20-30 minutes, then let stand for 10-20 minutes to form a mixture;

[0017] S2, adding 8-13 parts by weight of an antifoaming agent into the mixture, stirring and mixing for 5-10 minutes, then adding 2-6 parts by weight of temperature-sensitive reversible color powder and 1-3 parts by weight of additives, Stir for 3-8 minutes.

[0018] Furthermore, in a preferred embodiment of the present invention, the temperature-sensitive reversible color powder is pretreated before use: the temperature-sensitive reversible color powder is placed in a dopamine solution, and the pH is adjusted to 8-9 , add lign...

Embodiment 1

[0035] A kind of temperature-sensitive color-changing water-based ink for paper materials provided by the present embodiment:

[0036] Formula: 19 parts of polyvinyl alcohol, 2 parts of modified rosin resin, 2.44 parts of urea, 63.41 parts of deionized water, 9.76 parts of tributyl phosphate, 0.73 parts of wetting agent (PE-100), 1.66 parts of BYK-333 leveling agent 2.5 parts, temperature-sensitive reversible color powder 2.5 parts, auxiliary agent (silica sol and chitosan quaternary ammonium salt with a mass ratio of 4:1) 2.5 parts.

[0037] Preparation steps:

[0038] (1) Put the temperature-sensitive reversible color powder in 0.7g / L dopamine solution, adjust the pH to 8, add 0.14g lignosulfonate, stir for 4 hours, separate and dry.

[0039] (2) Stir the binder, crosslinking agent, solvent, leveling agent and wetting agent at a constant temperature of 90°C at 160r / min for 25min, and after standing for 20min, a milky white sol system mixture is formed;

[0040] (3) Add the...

Embodiment 2

[0042] A kind of temperature-sensitive color-changing water-based ink for paper materials provided by the present embodiment:

[0043] Formula: 15 parts of polyvinyl alcohol, 1.5 parts of modified rosin resin, 3 parts of urea, 65 parts of deionized water, 11 parts of tributyl phosphate, 1.05 parts of wetting agent (PE-100), 1.86 parts of BYK-333 leveling agent 2.5 parts, temperature-sensitive reversible color powder 2.5 parts, auxiliary agent (silica sol and chitosan quaternary ammonium salt with a mass ratio of 4:1) 2.5 parts.

[0044] Preparation steps:

[0045] (1) Put the temperature-sensitive reversible color powder in 0.7g / L dopamine solution, adjust the pH to 8, add 0.14g lignosulfonate, stir for 4 hours, separate and dry.

[0046] (2) Stir the binder, crosslinking agent, solvent, leveling agent and wetting agent at a constant temperature of 90°C at 160r / min for 25min, and after standing for 20min, a milky white sol system mixture is formed;

[0047] (3) Add the defoame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com