Plastic heat discoloration coating and preparation method and application thereof

A temperature-sensitive color-changing and coating technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, coatings, etc., to achieve good solvent resistance and dispersion, excellent adhesion, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with examples, which are only preferred implementations of the present invention, and are not limitations of the present invention.

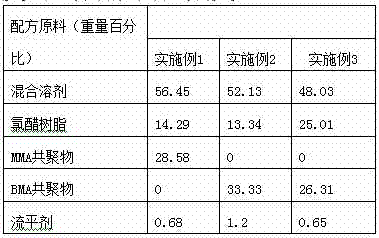

[0022] Prepare the semi-finished product dispersion according to the following formula.

[0023]

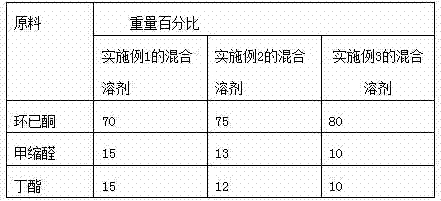

[0024] The mixed solvent formula is:

[0025]

[0026] Then make the plastic temperature-sensitive paint finished paint of direct construction according to the following formula.

[0027]

[0028] The plastic temperature-sensitive color-changing coating product detection and index that make by above-mentioned steps are as follows:

[0029]

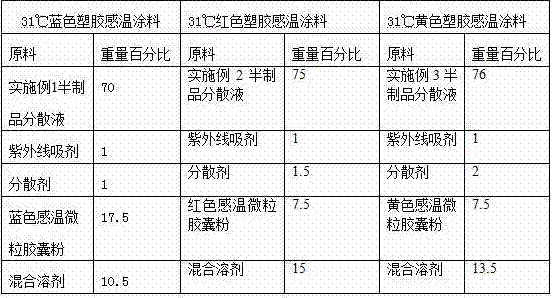

[0030] The temperature change effect of the above three examples of plastic temperature-sensitive color-changing oil (choose three of their natural colors)

[0031] The 31°C blue plastic temperature-sensitive paint is applied behind the plastic parts. When the temperature is lower than 31°C, the color of the paint is blu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com