Automobile sliding door multi-lock-body transmission mechanism

A technology of transmission mechanism and sliding door, which is applied to locks, building locks, building structures and other directions operated by mechanical transmission, and can solve problems such as inconvenience in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

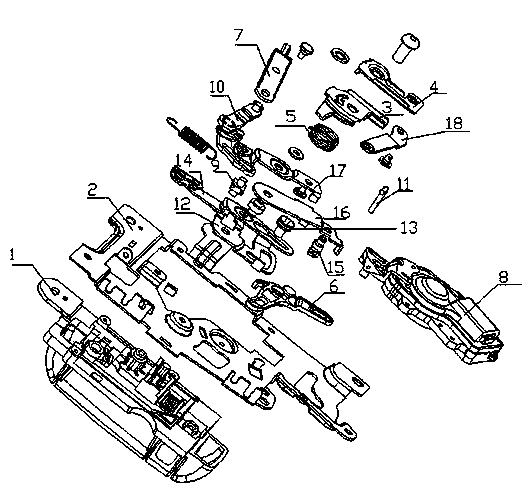

[0022] Such as figure 1 As shown, a multi-lock body transmission mechanism for an automobile sliding door is used for transmission when the front door lock is installed at the front end of the automobile sliding door, the rear door lock is installed at the rear end, and the guide rail lock is installed at the lower end. 1 and a base plate 2, the inward opening handle assembly is fixed on one side of the base plate, and the inward opening handle assembly is sequentially positioned with an inward opening rocker arm 3 and a limit opening rocker arm 4. A torsion spring 5 is set on the rocker arm; the other side of the bottom plate is riveted with a central control linkage arm 6, a child safety bar 7, a lock assembly 8 and a riveted shaft 9, and a child safety bar is fixedly connected to the child safety bar. The safety linkage arm 10, the child safety linkage arm snaps into the inner opening handle assembly; the locker assembly is fixedly connected with the button of the inner ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com