Non-contact space cross transmission magnetic gear and its manufacturing method and applicaiton

A magnetic gear and cross-drive technology, applied in the directions of transmission boxes, magnetic materials, magnetic objects, etc., can solve the problems of complex production process, inability to realize non-contact space cross-shaft transmission, etc., and achieve low noise, simple structure, and low vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

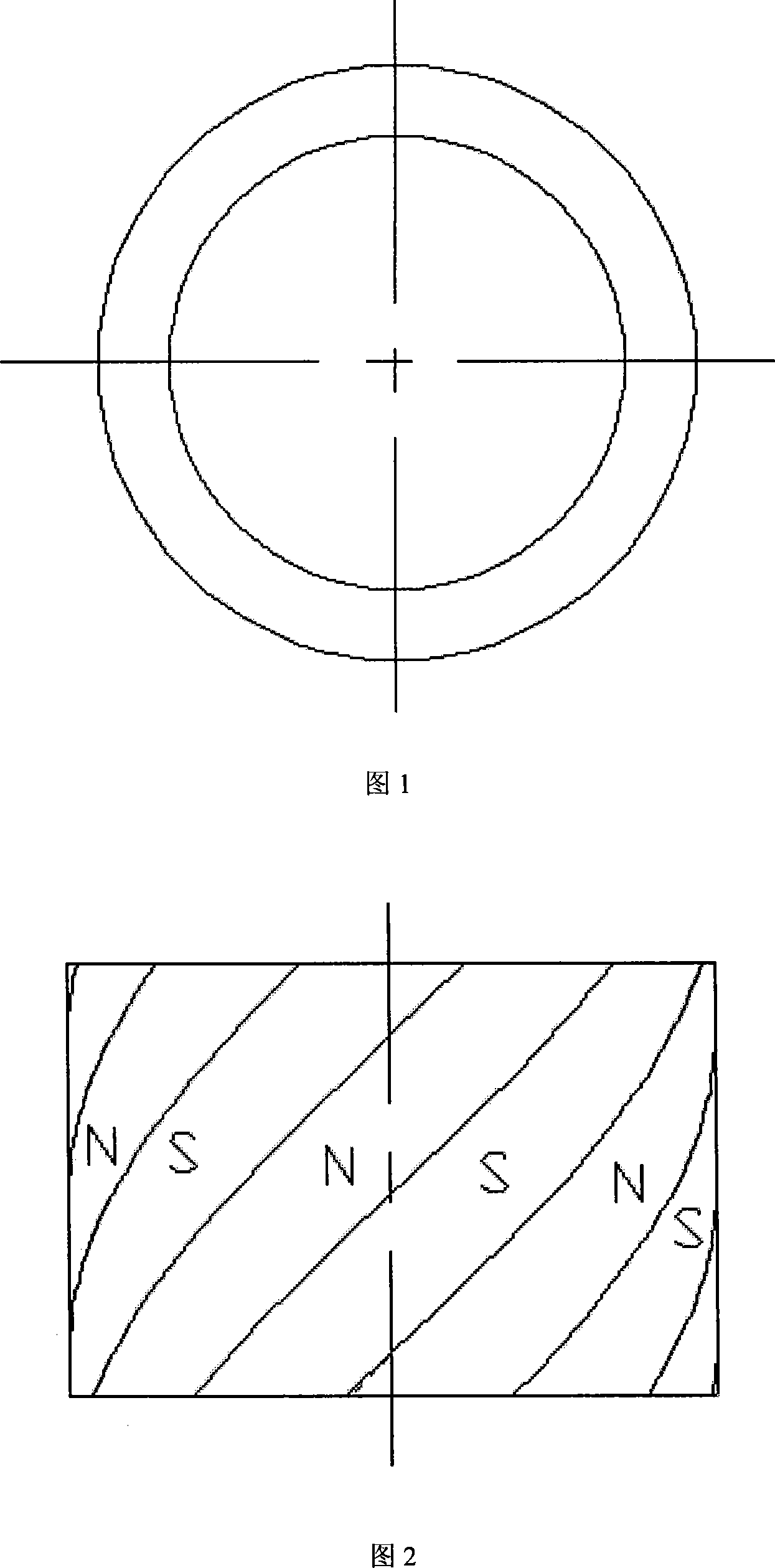

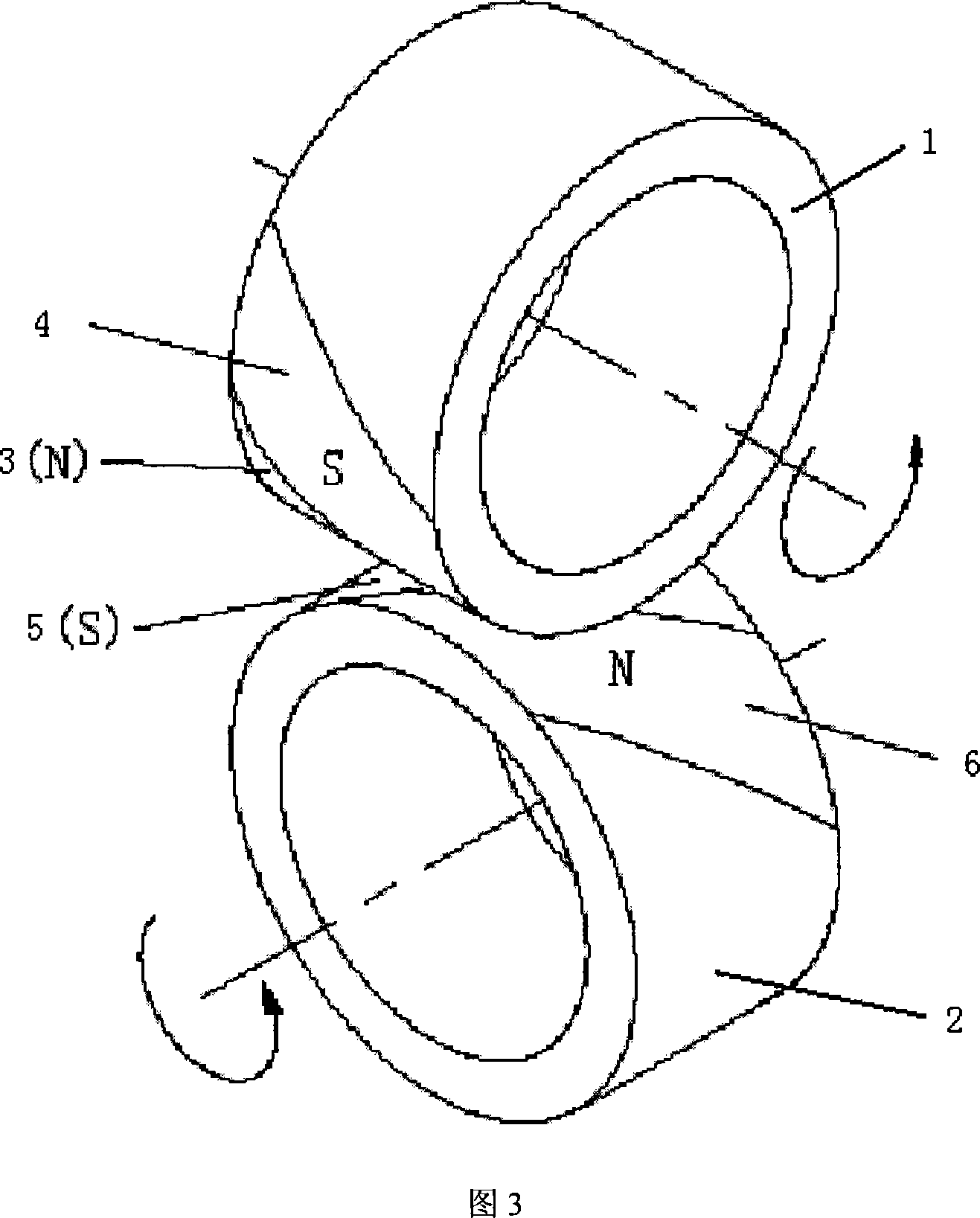

[0016] A preferred embodiment of the present invention is: see Fig. 1 and Fig. 2. The magnetic gear for non-contact space cross transmission is made of NdFeB permanent magnet material through bonding and pressing. Its outer surface is smooth and complete. Heteropolar multi-pole magnetic gears. Figure 1 shows that the non-contact space cross transmission magnetic gear is a complete cylinder, and Figure 2 shows that the magnetic pole inclination angle is 45° helix angle. As shown in Figure 3, the two above-mentioned magnetic gears are installed according to the space cross axis, the two magnetic gears are non-contact, and there is an effective gap between them, and the 45° magnetic poles of the two magnetic gears are exactly matched to realize the transmission. The gear transmission of the present invention is not a tooth meshing transmission, but relies on the attraction and repulsion between the positive and negative poles of the magnetic gears to generate torque to realize t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com