Sealing structure of wooden door

A technology of sealing structure and wooden door, which is applied in the direction of sealing device, etc., can solve the problems of wooden door deformation, influence of humid environment, and failure to close the door, so as to avoid loss, prevent dust from entering the room, and speed up cooling or heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

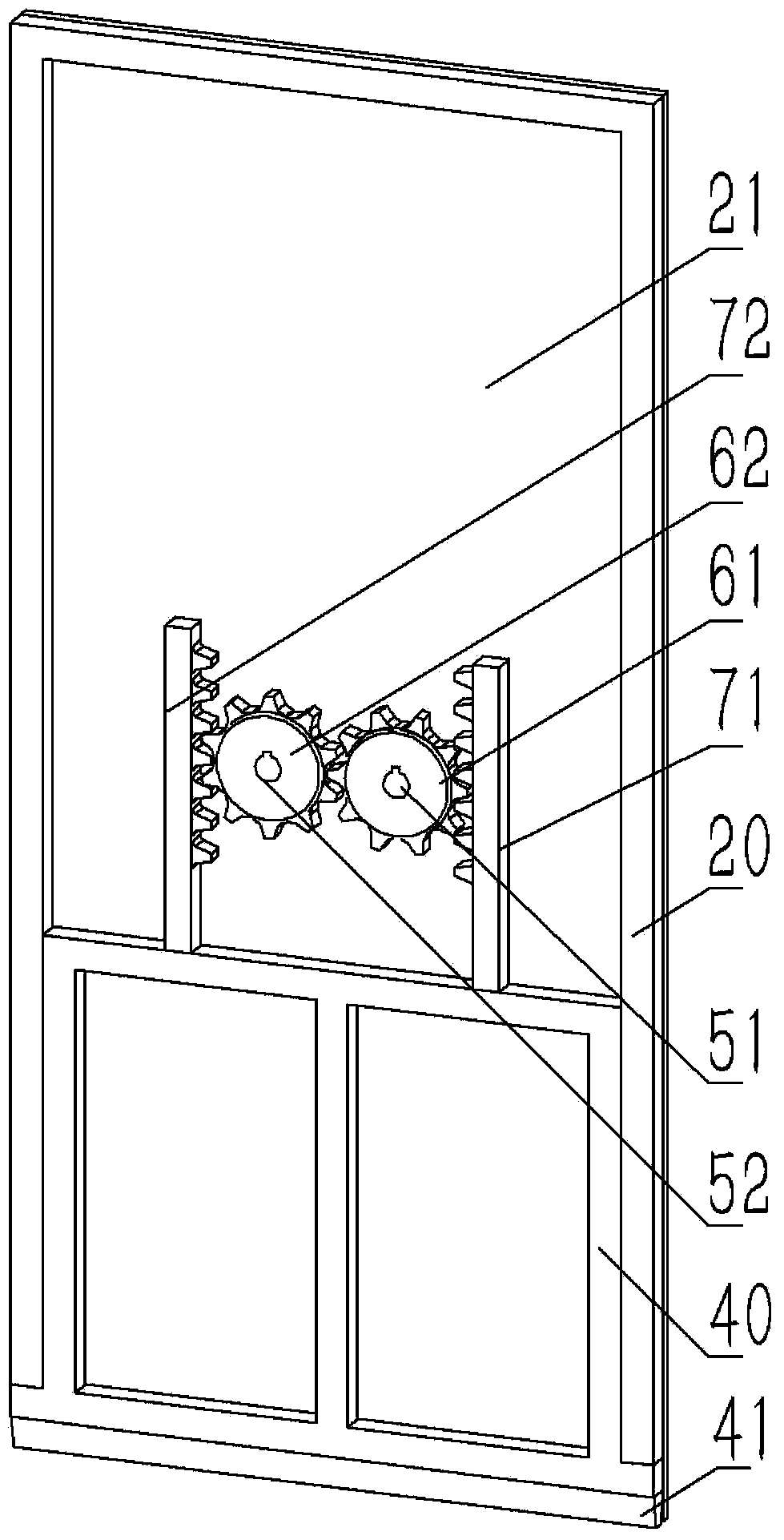

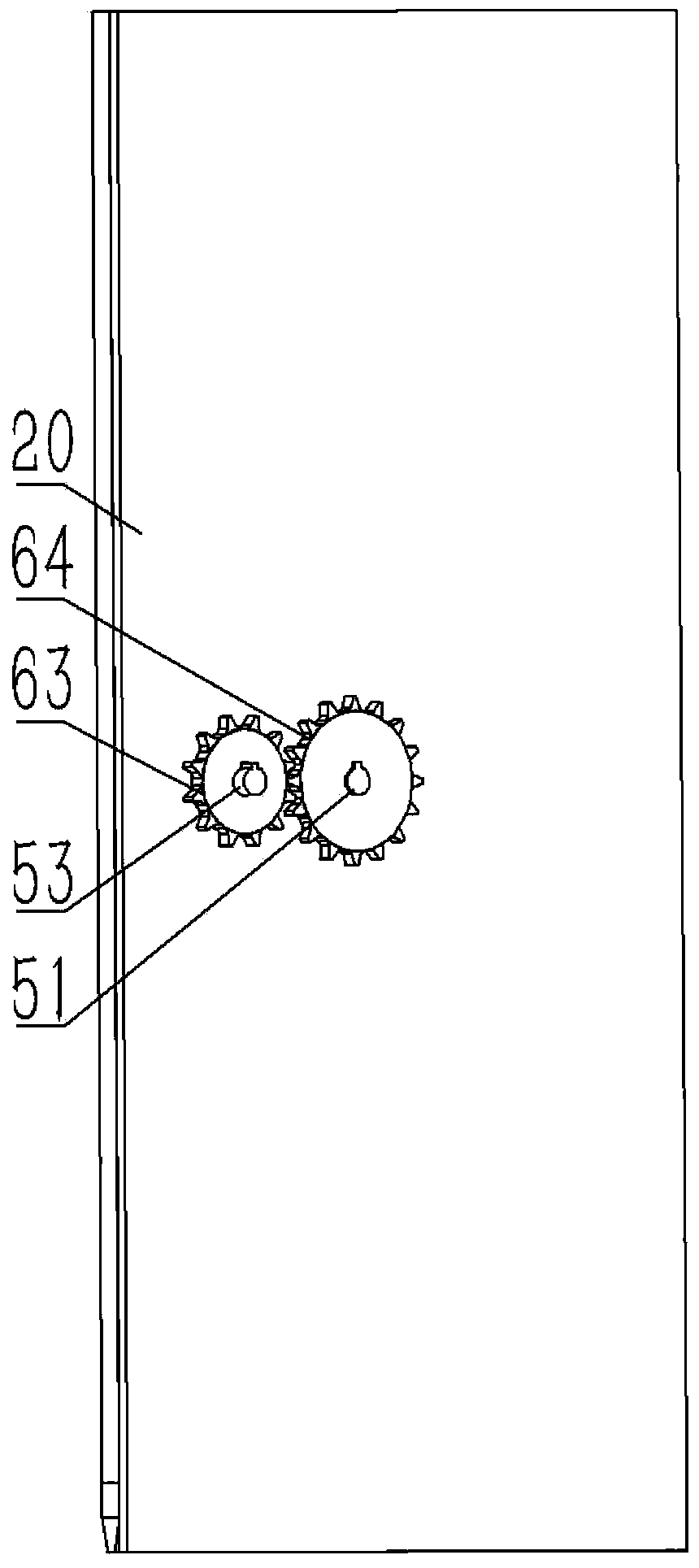

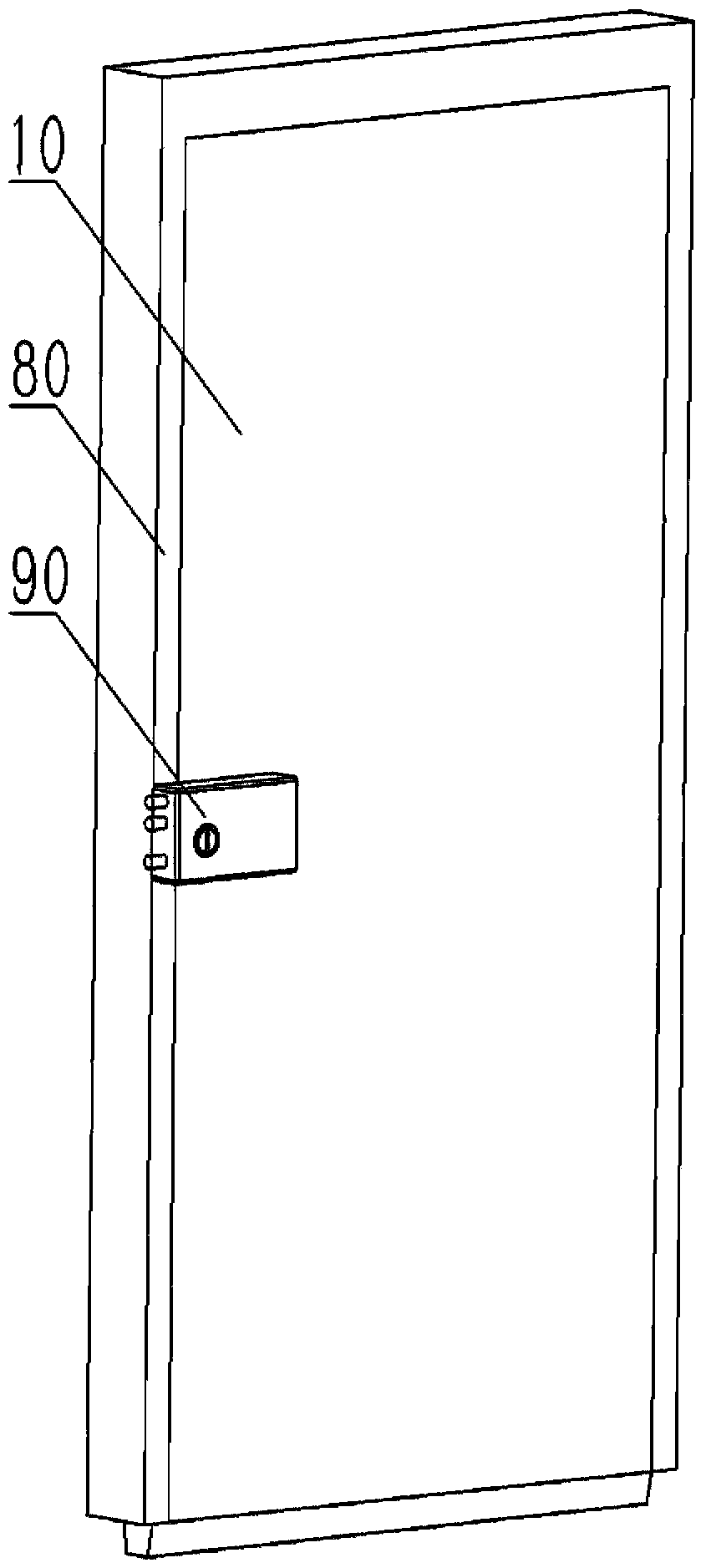

[0017] Example: see Figures 1 to 4 As shown, a wooden door sealing structure includes two sets of panels 10 and a door frame 80, a set of panels 10 is fixed with a door lock 90, a core plate 20 is arranged between the two panels 10, and a groove cavity 21 is formed in the core plate 20. , the groove cavity 21 is inserted with a bracket 40, the lower end of the bracket 40 is fixed with a rubber strip 41, the upper end of the bracket 40 is respectively fixed with a first rack 71 and a second rack 72, the first rack 71 and the second rack The first gear 61 and the second gear 62 are meshed sequentially on the 72, and the first gear 61 and the second gear 62 are meshed together. The first gear 61 and the second gear 62 are sequentially hinged on the first shaft 51 and the second gear On the two rotating shafts 52, both ends of the first rotating shaft 51 and the second rotating shaft 52 are hinged on both sides of the cavity 41; one end of the first rotating shaft 51 passing thro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap