Thermostatic heat management power machine cooling system

A cooling system and power machine technology, applied in the direction of engine cooling, engine components, combustion engines, etc., can solve the problems of inability to control temperature and achieve excellent performance and good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

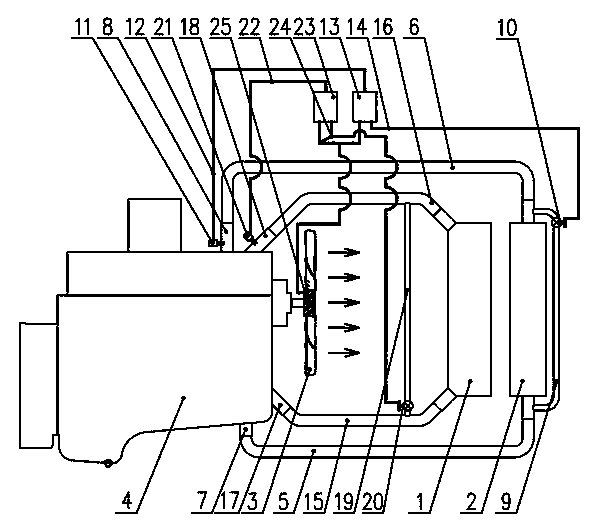

[0014] like figure 1 As shown, the supercharged air intake intercooler 1 of the present invention and the coolant radiator 2 are installed together in series, and the cooling fan 3 is installed on the engineering power machine 4 near the supercharged air intake intercooler 1 side.

[0015] The coolant radiator 2 is connected to the power machine water inlet 7 and water outlet 8 through the water inlet pipe 5 and the water outlet pipe 6, and the water inlet pipe 5 and the water outlet pipe 6 are connected through a bypass water pipe 9, and the coolant temperature control is installed in the bypass water pipe 9 An electronic proportional valve 10; a coolant temperature sensor 11 is installed at the water outlet 8 of the power machine, the coolant temperature sensor 11 is connected to the coolant temperature controller 13 through the wire harness 12, and the coolant temperature controller 13 is connected to the coolant temperature through the control wire harness 2 14 Temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com