Vertical wind power generation blade

A wind power generation blade, vertical technology, applied in the field of vertical wind power generation blades, can solve problems such as difficulty in improving wind power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

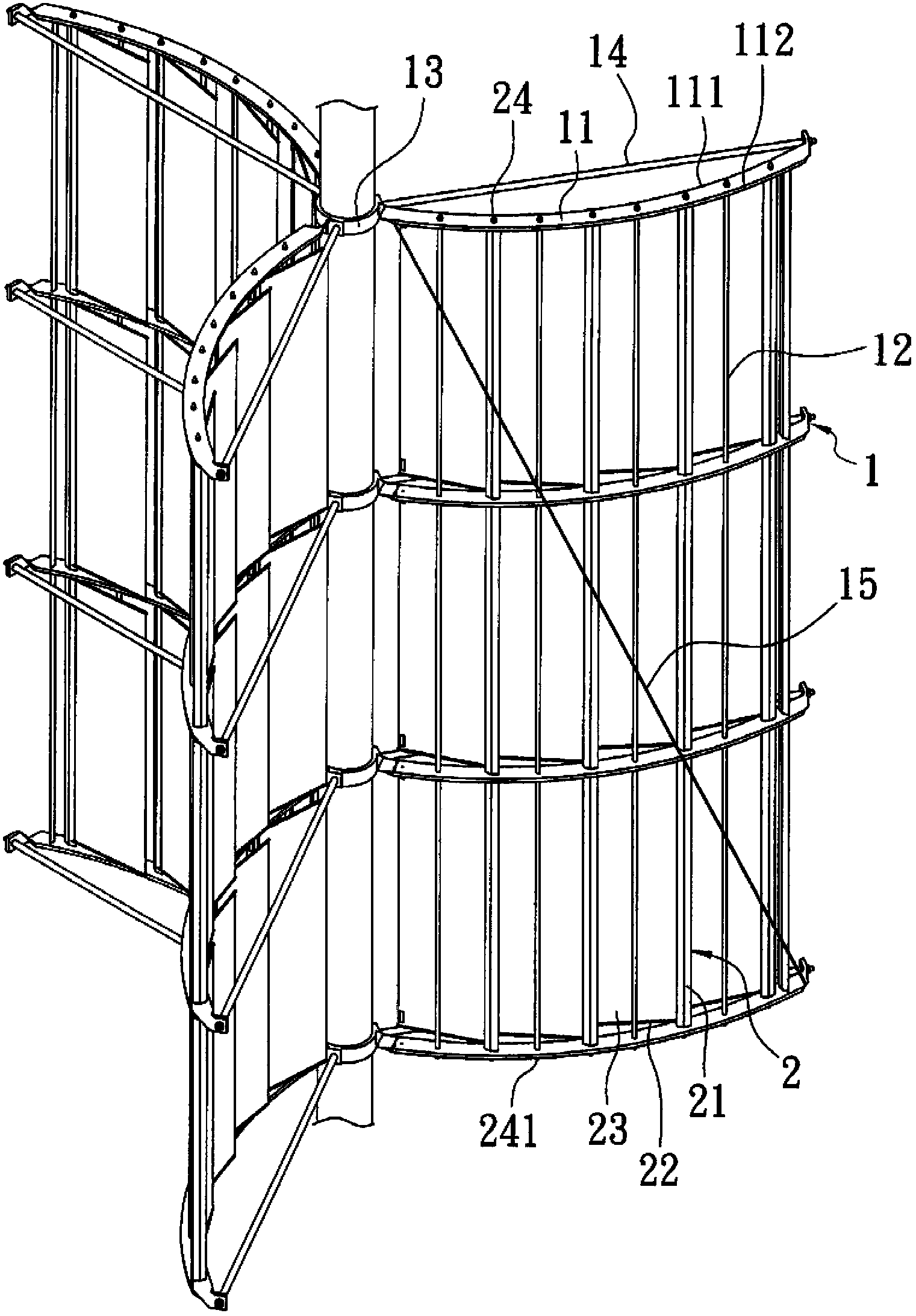

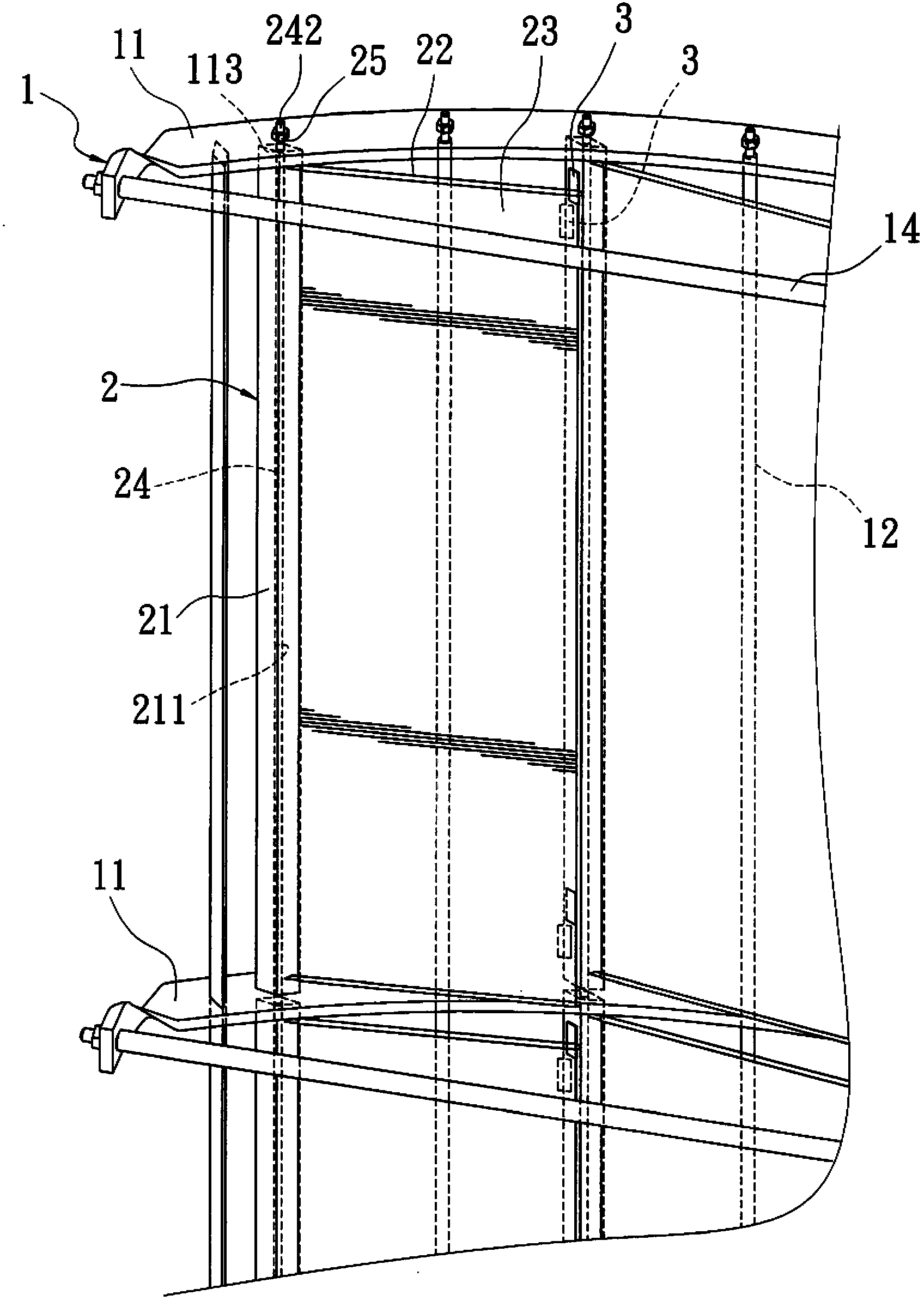

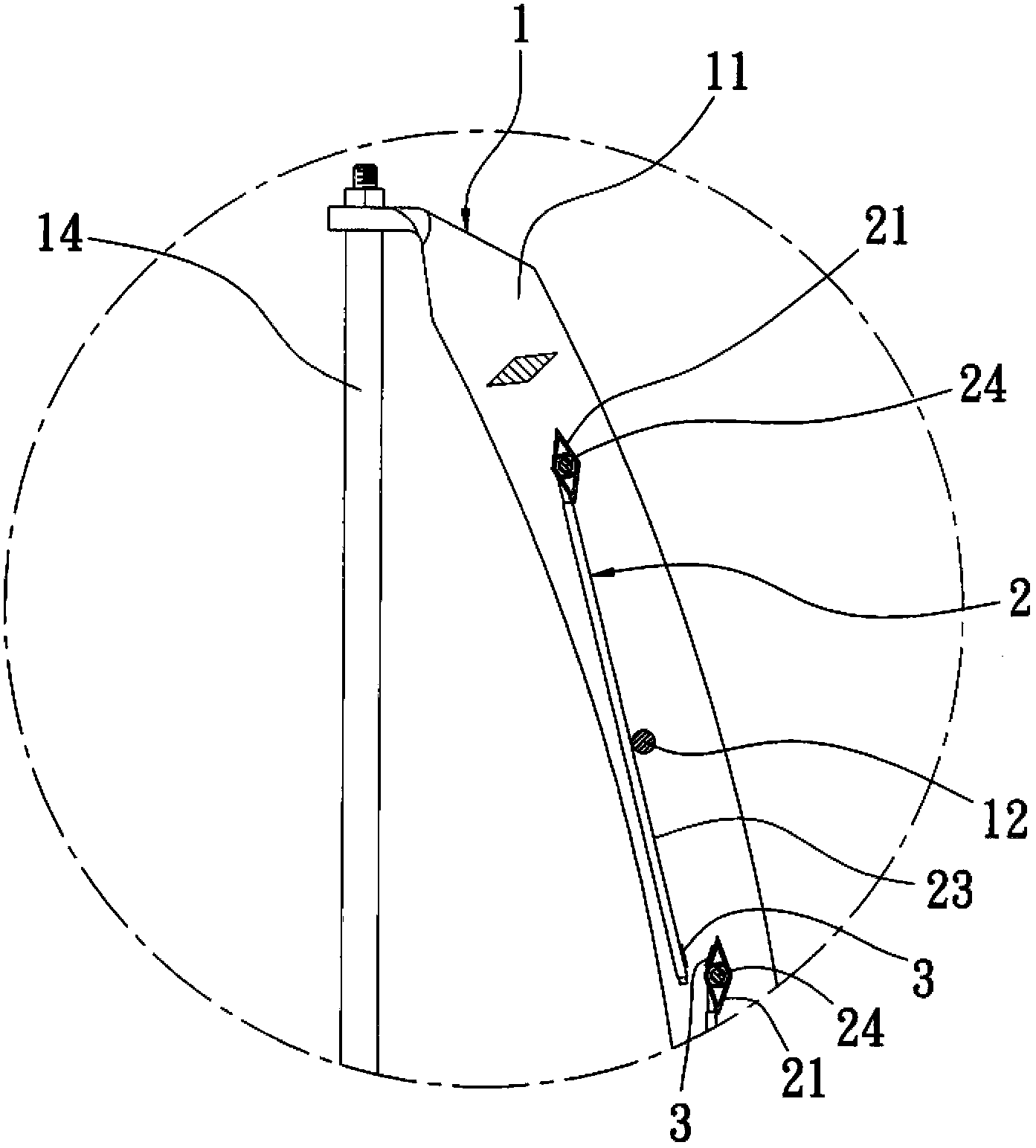

[0032] First, see figure 1 image 3 As shown, the vertical wind power generation blade of the present invention is mainly composed of a blade frame body 1, a blade main body 2 and a buffer member 3; wherein:

[0033] The blade frame body 1 includes a plurality of sets of vertical plates 11 set up separately from top to bottom, and the sets of vertical plates 11 are arc-shaped, and the two sides of the set of vertical plates 11 are formed with relatively arc-concave windward surfaces 111 and the arc-convex leeward surface 112, and a stopper 12 is set between the upper and lower set of vertical plates 11, and the set of vertical plates 11 is located between the two stoppers 12 to be provided with a pivot hole 113, and the set of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap