A High Stiffness Composite Reflective Film

A technology of composite reflection and reflective film, which is applied in the field of reflective film, can solve the problems of film bending, film stiffness reduction, and reflective film density decrease, and achieve the effect of not easy film bending and good stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

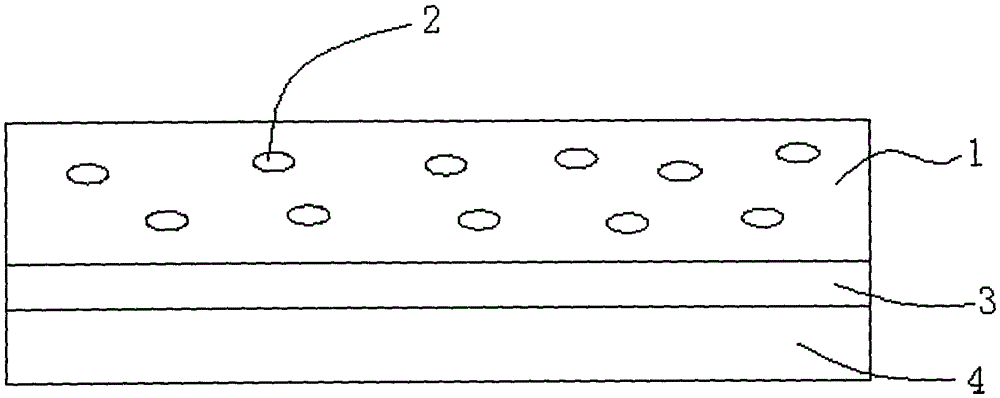

[0015] Reference figure 1 , A high-stiffness composite reflective film, comprising a reflective film base layer 1, said reflective film base layer 1 has microbubbles 2 inside, and an adhesive layer 3 is provided on the back of said reflective film base layer 1, said adhesive layer 3 is pasted with a reinforcement layer 4. The adhesive layer 3 can be an acrylate adhesive, a polyurethane adhesive, an epoxy adhesive, or a phenolic resin adhesive.

[0016] In this embodiment, the material of the reflective film base layer 1 is PET; during molding, the PET of the reflective film base layer is mixed with nucleating particles that are incompatible with PET, and the PET masterbatch mixed with the nucleating particles is melted and plasticized After casting and biaxial stretching, microbubbles are formed in the PET film with nucleated particles as the center. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com