Method for mixing myopia-preventing spot-color ink

An anti-myopia, ink technology, applied in ink, home appliances, applications, etc., can solve problems such as low precision and inability to meet the quality requirements of printed matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Taking 500nm light yellow-green as an example, the preparation method and process of the anti-myopia yellow-green color of the present invention will be described in detail.

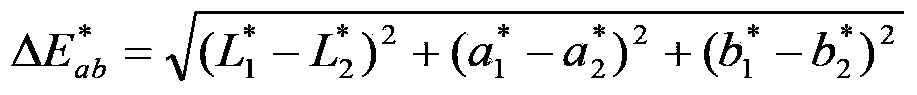

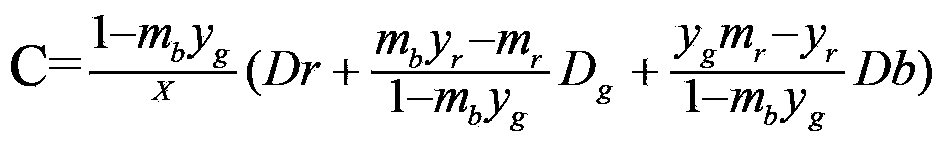

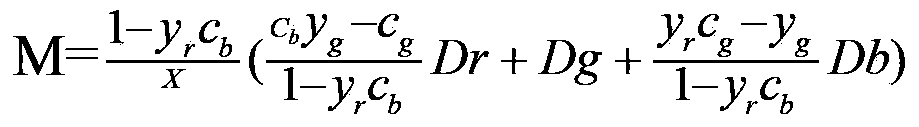

[0052] Step 1, through the CIEXYZ chromaticity coordinates, search for the spectral tristimulus value of the anti-myopia color block corresponding to 500nm X=0.0049, Y=0.3230, Z=0.2720 and chromaticity coordinates x=0.0082, y=0.5384, z=0.4534, use CIE1976Lab horseshoe-shaped curve, find the yellow-green color block to prevent myopia in the horseshoe-shaped curve;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com