Reactivity control method of pebble-bed high-temperature gas cooled reactor and telescopiform control rod

一种高温气冷堆、控制棒的技术,应用在核反应的控制、反应堆、减少温室气体等方向,能够解决反应堆操纵人员大操作难度、运行可靠性要求高、易于发生事故等问题,达到简化启动及运行控制操作、提高反应性价值、降低设计复杂性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation manner of the present invention will be further described below in conjunction with the drawings and embodiments. The following examples are only used to illustrate the present invention, but not to limit the scope of the present invention.

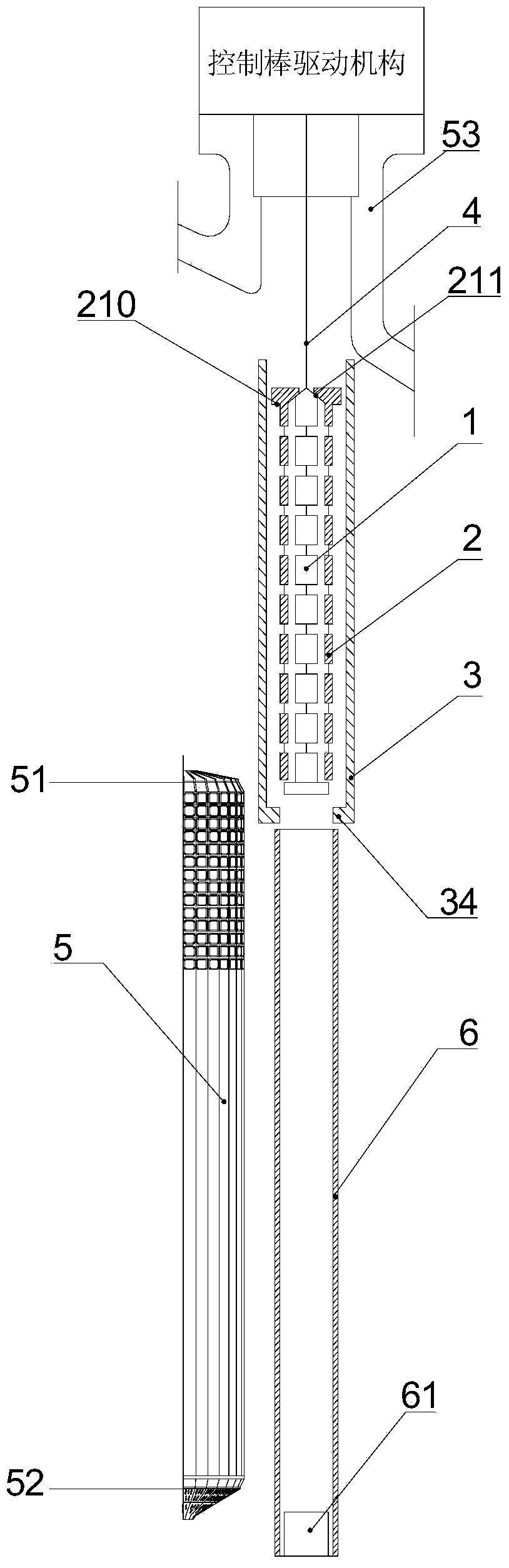

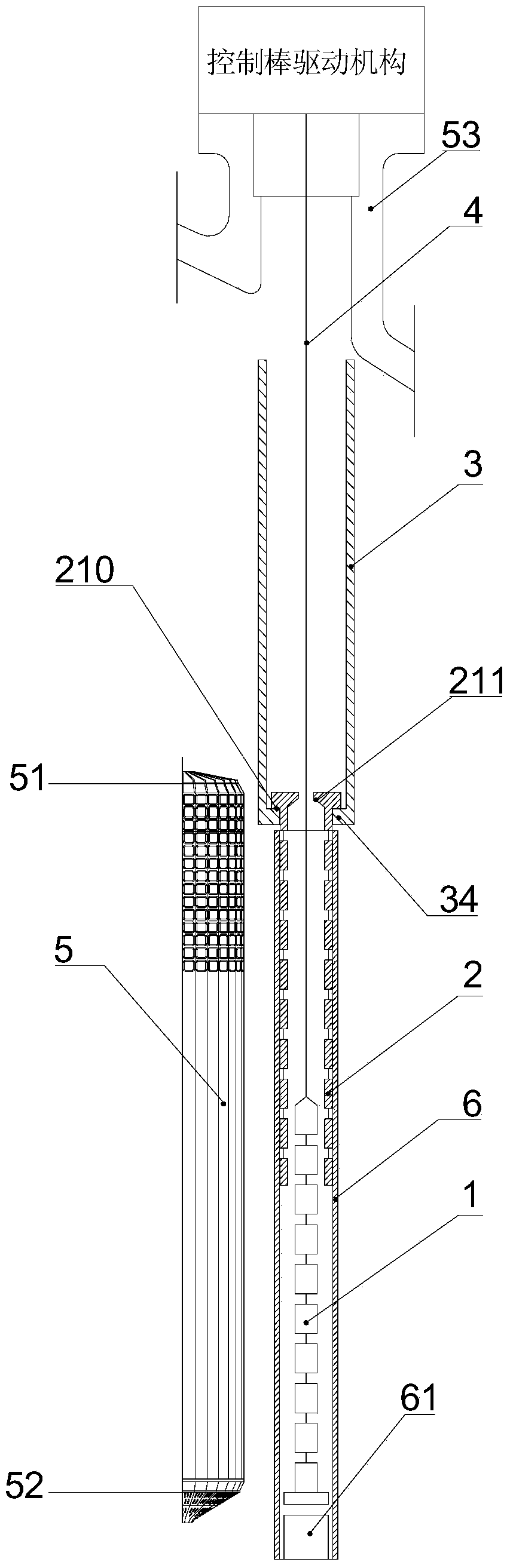

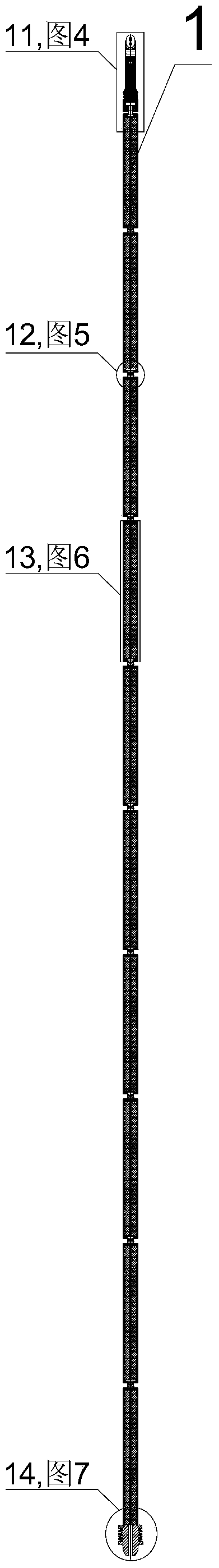

[0048] Such as figure 1 and figure 2 As shown, it is a schematic diagram of the operation of the telescopic control rod according to the embodiment of the present invention. The telescopic control rod includes: an inner rod 1 , an outer rod 2 and a guide cylinder assembly 3 . The inner rod 1 is connected with the chain 4 of the control rod driving mechanism through the joint head assembly, and moves up and down in the guide cylinder assembly 3 and the graphite channel 6 of the control rod under the drag of the driving mechanism. The lower limit of its movement is limited by the maximum length of the chain 4, Reaching the lower edge 52 of the reactor active area, the upper limit of its movement is limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com