Hydrocolloid stabilized dehydrated food foam

A hydrocolloid, food technology, applied in the field of food combination food, to achieve the effect of shortening the dehydration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

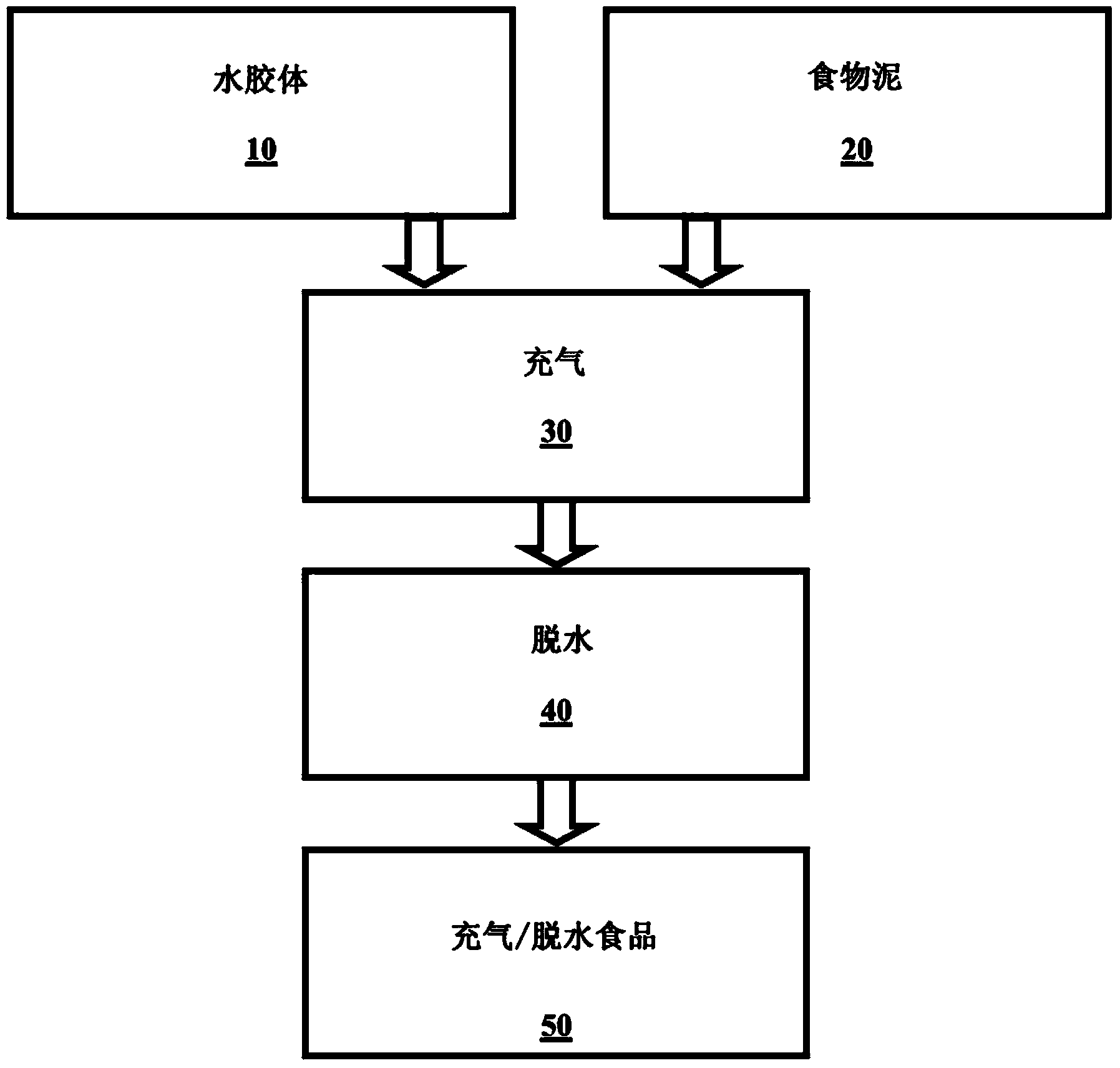

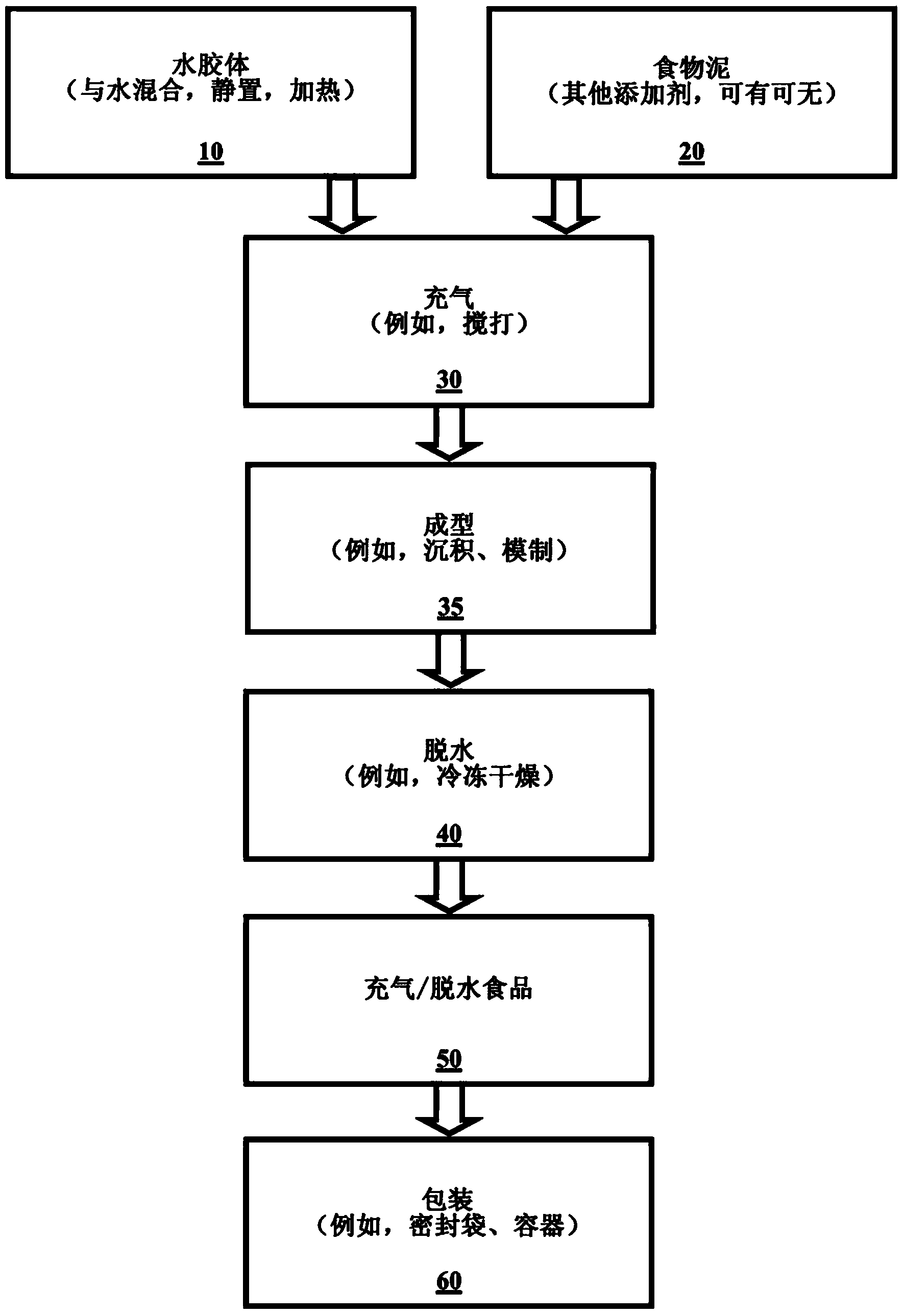

Method used

Image

Examples

Embodiment 1

[0103] Example 1 - Preparation of Vegetable or Fruit Puree Foam

[0104] A method for preparing the vegetable (such as broccoli, carrot, etc.) or fruit (such as tomato, strawberry, etc.) puree foam of the present invention will be described below.

[0105] Weighing: Each component is taken out from the warehouse and weighed accurately to ensure that the deviation from the target weight specified in the formula is not greater than 1%.

[0106] Mixing / Aerating: This operation consists of three steps:

[0107] (1) First gently mix the gelatin with cold water (municipal tap water, <10°C) for 1 minute and keep for 5 minutes to fully absorb the water. The mixture was then heated to 60°C to completely dissolve the gelatin in solution.

[0108](2) Mix the remaining ingredients (each pureed vegetable or fruit, seasoning and cheese powder) with a mixer to form a uniform slurry.

[0109] (3) After adding the gelatin solution to the puree mixture, aerate the mixture with a mixer at hig...

Embodiment 2

[0113] Example 2 – Sweet Potato Recipe (Whipping Cream)

[0114] The sweet potato foam food of the present invention is prepared using the following ingredients, materials and steps:

[0115] Ingredients: 3 / 4 cup Heavy Cream; 1 / 4 cup mashed sweet potato; 1 / 2 cup (50 grams) caster sugar and 1 / 8 teaspoon vanilla extract.

[0116] Materials: electronic scale; KitchenAid stand mixer w / whisk attachment; refrigerator.

[0117] Operation steps: (1) Weigh out all ingredients. (2) Combine and place in the bowl of a KitchenAid mixer. (3) Beat at high speed until soft peaks form (~5 minutes). (4) Refrigerate for later use.

[0118] Notes: (1) Once freeze-dried, the resulting food tissue melts well in the mouth. (2) Refrigerate the bowl of the whisk for faster frothing.

Embodiment 3

[0119] Example 3 - Sweet Potato Formulation (Nitrous Gelatin)

[0120] The sweet potato foam food of the present invention is prepared using the following ingredients, materials and steps:

[0121] Ingredients: 2 tsp / 9 g Knox Original Gelatin (powdered gelatin); 1 / 2 cup water; 1 / 4 cup mashed sweet potato; and 1 / 4 tsp McCormick Pumpkin Pie Spice.

[0122] Materials: electronic scale; medium bowl; small saucepan; stovetop; refrigerator; iSi pint-sized stainless steel cream whisk;

[0123] Steps: (1) Combine sweet potato mash and pumpkin spice in a medium bowl. (2) In a small saucepan combine the gelatin and water. (3) Heat the pan under medium-high heating conditions and keep stirring. (4) Simmer the mixture for a while or until all the gelatin is incorporated. (5) Add the hot homogeneous gelatin / water mixture to the puree and spices. (6) Whip / stir the contents of the bowl until blended. (7) Add the contents of the bowl to the container of the iSi Whisk and screw on the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com