Thermoplastic non-woven fabric

A technology of non-woven fabrics and thermoplastic fibers, which is applied in the direction of non-woven fabrics, textiles, papermaking, bandages, etc., which can solve the problems of non-woven fabrics, such as the difficulty of dimensional changes in softness and width, poor softness, etc., and reduce the insufficient coating width , low size change, and small width size change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

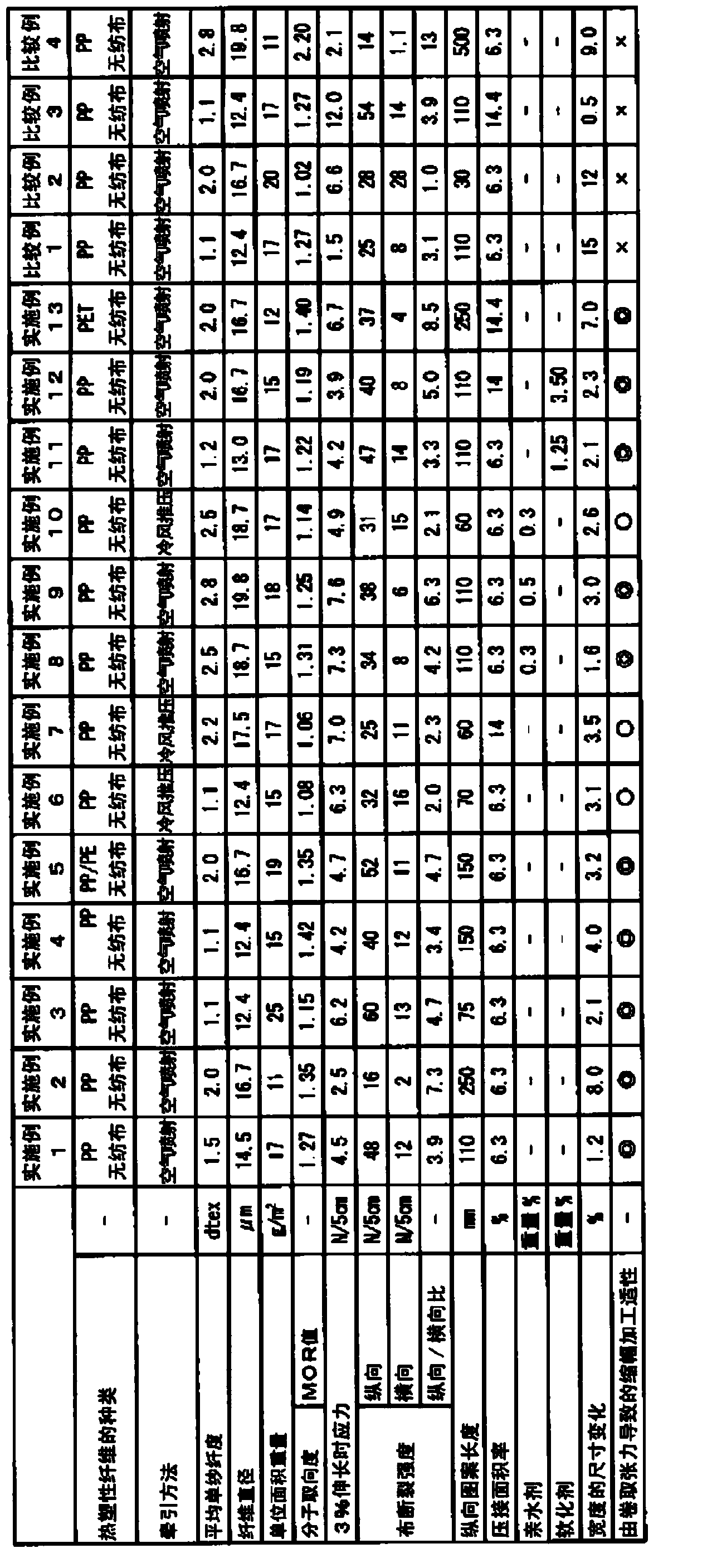

Examples

Embodiment 1

[0081] A polypropylene resin with an MFR of 60g / 10min (measured according to JIS-K7210 at a temperature of 230°C and a load of 2.16kg) is spunbonded through a nozzle diameter of φ0.4mm and a single hole discharge amount of 0.56g / min·Hole 1. Extruded under the condition of spinning temperature of 215°C, the filament group was drawn by a high-speed airflow traction device based on air jets, and extruded towards the moving collection surface in a manner with a longitudinal pattern length of 110 mm, to prepare an average single yarn denier of 1.5 Long fiber web of dtex.

[0082] Then, make the obtained fiber web pass between the flat roller and the embossing roller (pattern specification: diameter 0.425mm circle, staggered arrangement, horizontal spacing 2.1mm, vertical spacing 1.1mm, crimping area ratio 6.3%), at temperature The fibers are bonded to each other at 135°C and a linear load of 35kgf / cm to obtain a weight per unit area of 17g / m 2 long-fiber nonwovens.

Embodiment 2

[0084] Set the single-hole ejection amount as 0.90g / min·Hole, and the length of the longitudinal pattern as 250mm, and operate in the same manner as in Example 1 to obtain an average single yarn fineness of 2.0dtex and a weight per unit area of 11g / m 2 long-fiber nonwovens.

Embodiment 3

[0086] The length of the longitudinal pattern is set to 75mm, and the same operation as in Example 1 is obtained to obtain an average single yarn fineness of 1.1dtex and a weight per unit area of 25g / m 2 long-fiber nonwovens.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap