Feeding system of dough mixer

A technology of feeding system and dough mixer, which is applied to the structural parts of mixing/kneading machinery, etc., which can solve the problems of poor dough uniformity, poor mixing effect of flour and water, and low efficiency, so as to achieve good uniformity and improve aging Effect, the effect of reducing the face-to-face time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

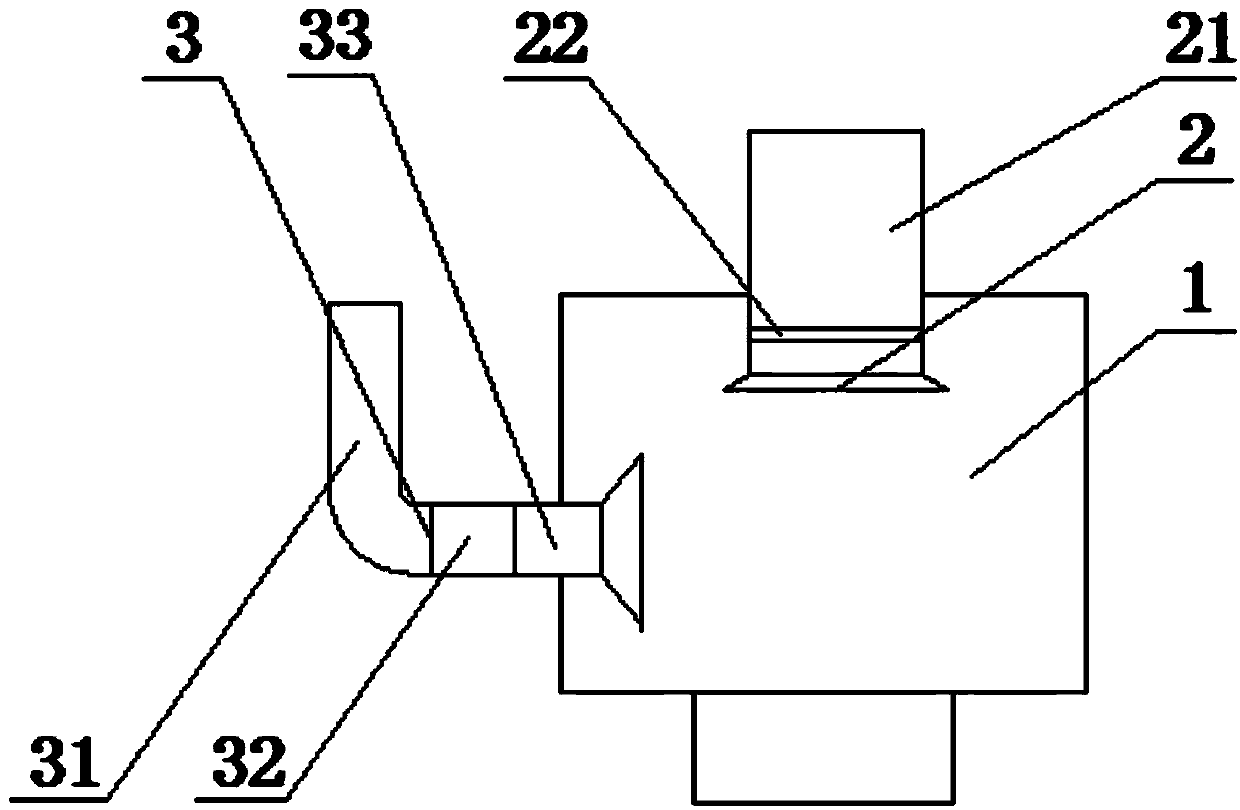

[0013] Such as figure 1 As shown, the present invention provides a feeding system for a dough mixer, comprising a box body 1, a flour delivery system 2 and a water delivery system 3, and the flour delivery system 2 and the water delivery system 3 are all arranged in the box body 1; the flour delivery system 2 includes flour pipeline 21 and vibrating sieve 22, and vibrating sieve 22 is arranged in flour pipeline 21; Later, the humidifier 32 and the water mist sprayer 33 are both arranged at the end of the water delivery pipeline 31 .

[0014] The working process of this example: before the fabric enters the dough mixer, the flour is conveyed into the flour pipeline 21, passes through the vibrating sieve 22, and the control system controls the vibrating sieve 22 to vibrate, so that the flour is distributed in a loose form and slowly falls into the box 1 At the same time, water is delivered to the water pipeline 31, first through the humidifier 32, the water is turned into a wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com