Manufacturing method for three-component regular-triangular platy body

A technology of equilateral triangle and production method, which is applied in the direction of cardboard items, can solve the problems of easy falling off and infirmity of the combination method, and achieve the effect of increasing aesthetic feeling and appreciation, not easy to fall off, and easy to plug and connect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

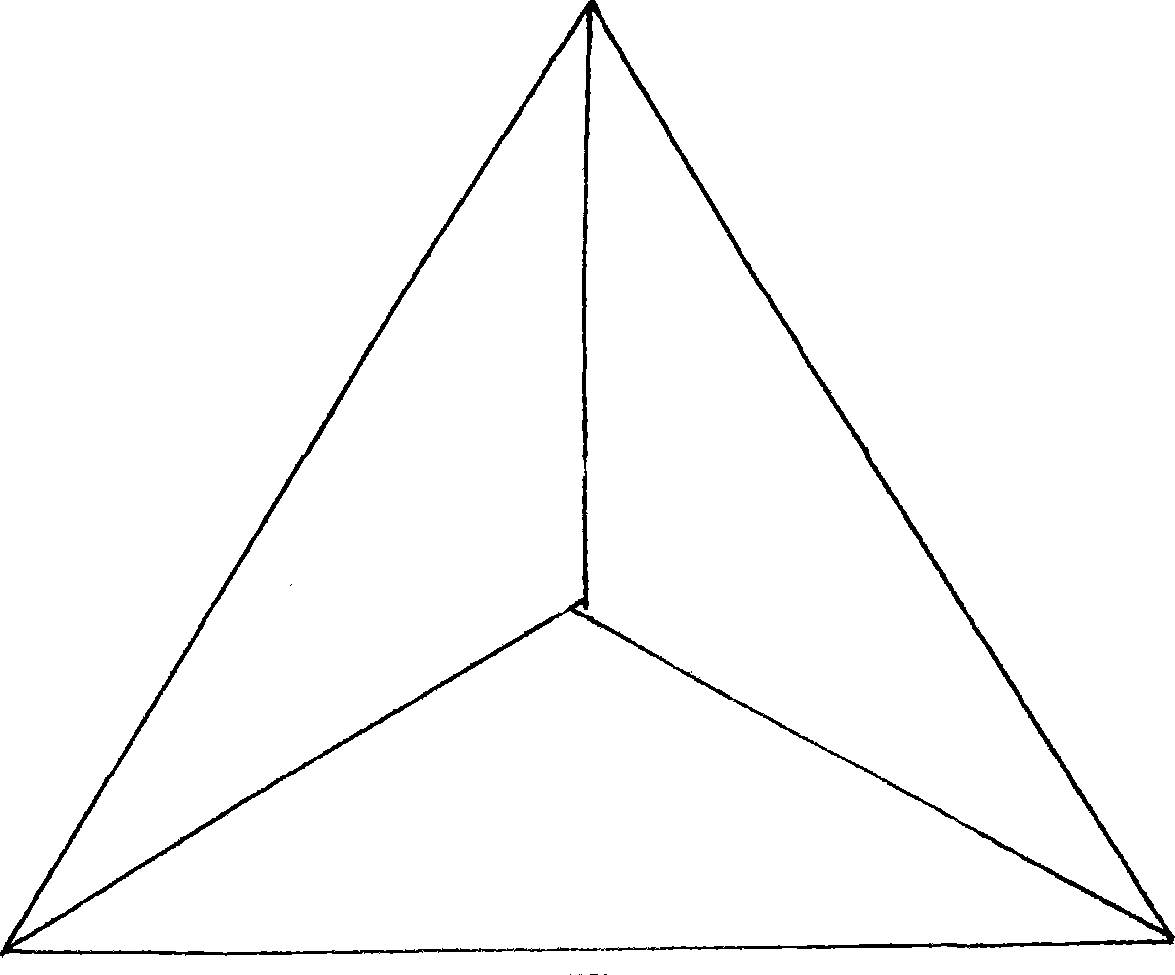

[0018] The three-component regular triangular plate is completed by three identical components, namely the first component, the second component and the third component;

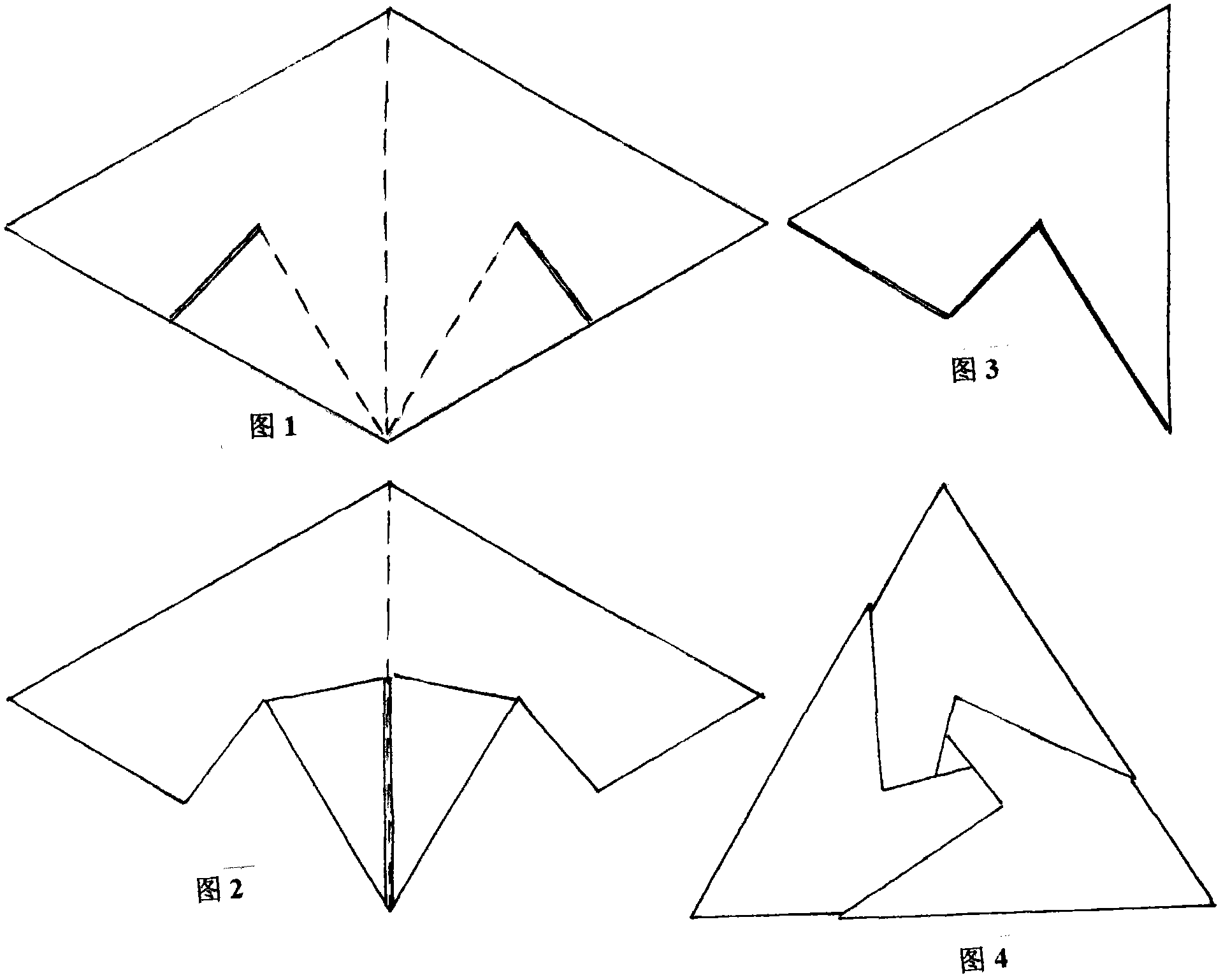

[0019] The production method of the components: take the diamond-shaped paper, the two obtuse angles are up and down, and the two acute angles are on the left and right, use a dotted line to represent the positive fold line of the front half; make a obtuse diagonal line positive fold line, divide the diamond-shaped paper into two congruent equilateral triangles on the left and right; Make an oblique positive fold line between the midpoint of the equilateral triangle and the vertex of the lower obtuse angle of the rhombus paper; make an incision line to cut the paper from the midpoint of the equilateral triangle to the midpoint of the lower side of the equilateral triangle toward the acute angle of the rhombus paper, To the lower edge of the equilateral triangle; the angle formed by the incision line and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com