Double-end jaw-type wheel pair withdrawal machine

A claw-type, unloading machine technology, applied in the direction of wheels, tire installation, tire parts, etc., can solve the problems of insufficient rigidity, poor accuracy, and high requirements for press-fitting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

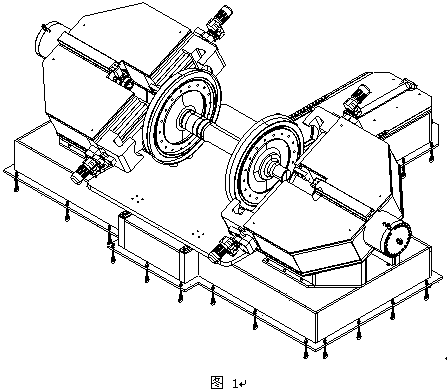

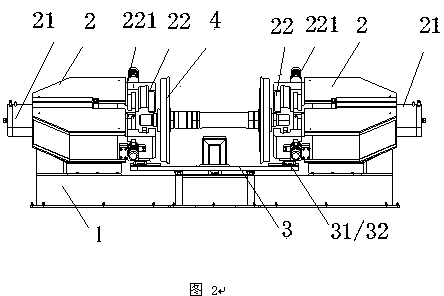

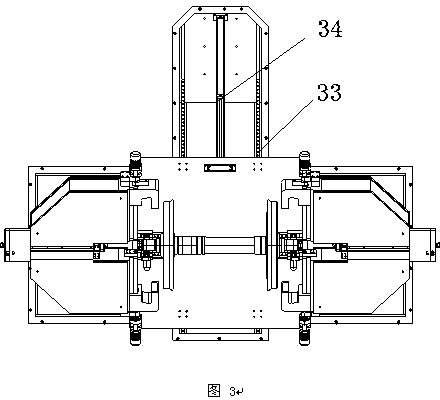

[0014] Such as Figure 1 to Figure 4 As shown, the present invention discloses a double-head jaw type wheel set unloading machine, which includes a base 1, left and right heads 2, left and right main oil cylinders 21, a workbench 3, a detection system, a hydraulic system, an electrical Control system, the two ends of the base are respectively equipped with U-shaped machine heads 2, and they are inclined at a certain angle to facilitate the entry and exit of workpieces; the main oil cylinder is installed in the middle of the U-shape, and claw mechanisms are provided at both ends of the U-shape, and the two sides of the U-shape are respectively An opening and closing drive device 221 is provided. During work, the wheels are held by the claws, and the main oil cylinder withstands the wheel shaft, and the wheels can be retracted; the base is provided with a workbench 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com