Pipe receiving arm

A technology of the main arm and the rear section, which is applied in the field of the takeover arm, can solve the problems of low production efficiency and inability to complete the transmission of large-diameter pipe fittings, and achieve the effect of safe and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

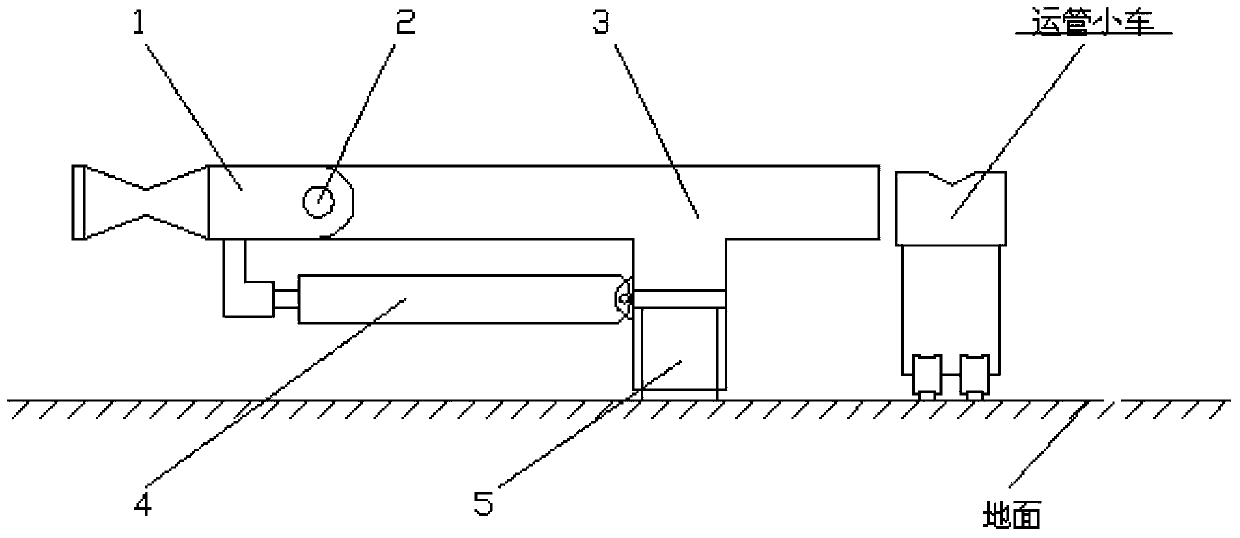

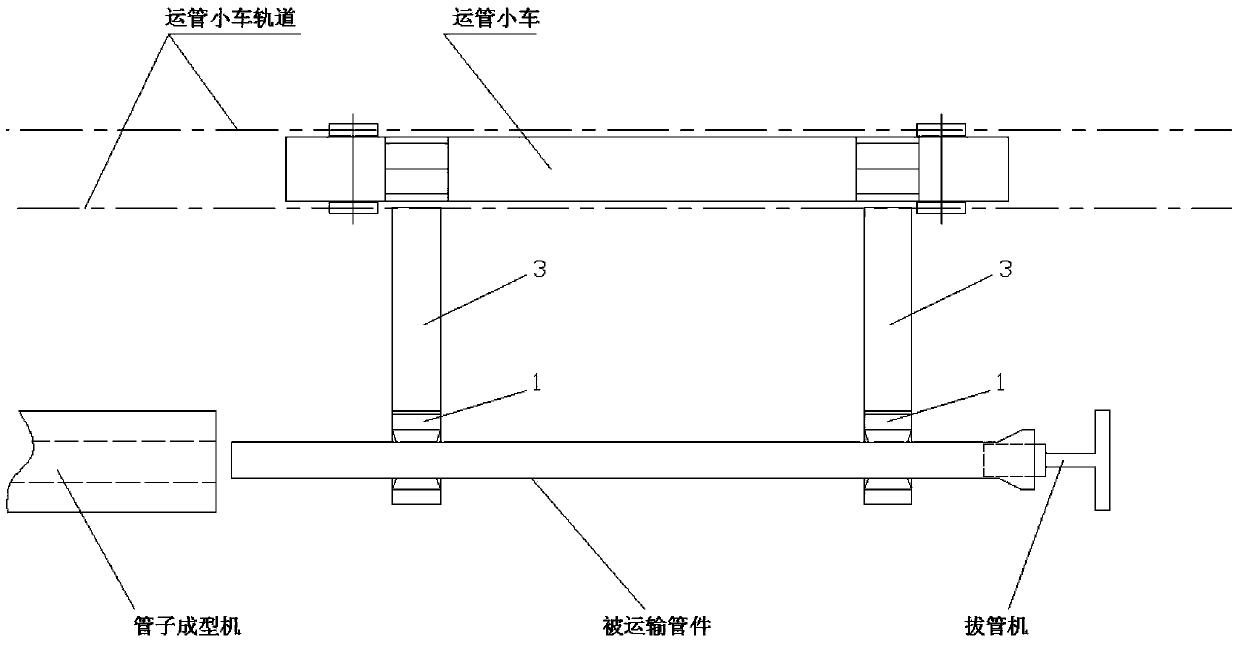

[0013] Introduce detailed technical scheme of the present invention below in conjunction with accompanying drawing:

[0014] Such as figure 1 As shown, the takeover arm includes a main arm front section 1, a main arm rear section 3, a pin shaft 2, an oil cylinder 4, a rotating base 5 and a hydraulic control system.

[0015] The front part of the front section of the main arm is a V-shaped structure, the rear section of the main arm is T-shaped, and the lower part of the T-shape is a hollow quadrangular prism, and the front section of the main arm is connected with the upper part of the rear section of the main arm through a pin shaft. The bottom of the rotating base is a bearing, and the bearing is fixed in a fixed groove on the ground. The lower part of the rear section of the main arm is sleeved on the rotating base. The cylinder body of the oil cylinder is connected with the lower part of the rear end of the main arm through a hinge, the outer end of the piston rod of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com