Artificial fish reef concrete and its preparation method

An artificial fish reef and concrete technology, which is applied in the cross field of building materials and marine engineering, can solve problems such as unfavorable algae attachment and growth, artificial fish reef life reduction, concrete expansion and deterioration, etc., to achieve seawater conservation and save transportation costs , the effect of delaying corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

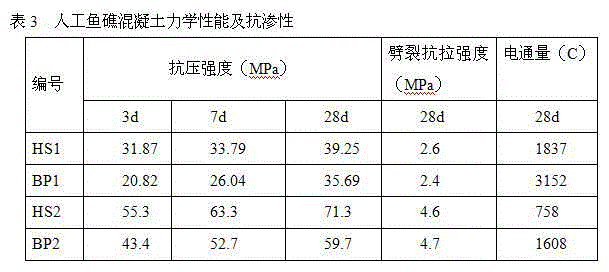

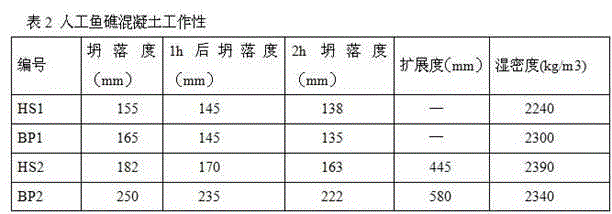

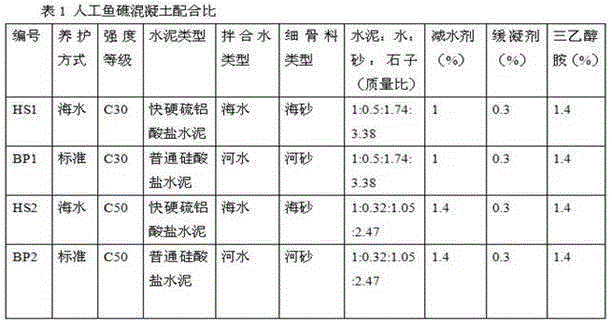

[0025] In order to make the object, technical solution and advantages of the invention clearer, the present invention will be further described in detail through specific examples below.

[0026] An artificial fish reef concrete, which is prepared from cement, mixing water, fine aggregate, stones and admixtures, wherein the mass ratio of cement: mixing water: fine bones: stones is 1: (0.3~ 0.5): (1 ~ 1.8): (2.4 ~ 3.4); the preparation method is as follows: first dry mix the mixture of cement, fine aggregate and stones in the mixer, then dissolve the admixture in the mixing water and pour it into Stir in the dry-mixed mixture; pour the artificial reef concrete after mixing; remove the formwork after 12 to 24 hours of artificial reef concrete pouring, and perform seawater curing for 7 to 28 days.

[0027] In this embodiment, the artificial fish reef concrete pouring time is preferably 24 hours, and the artificial fish reef concrete pouring seawater curing is preferably 28 days. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com