Seam structure with reversed filter function and construction method

A construction method and functional technology, applied in the direction of basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of high cost, inability to have both drainage and soil protection functions, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

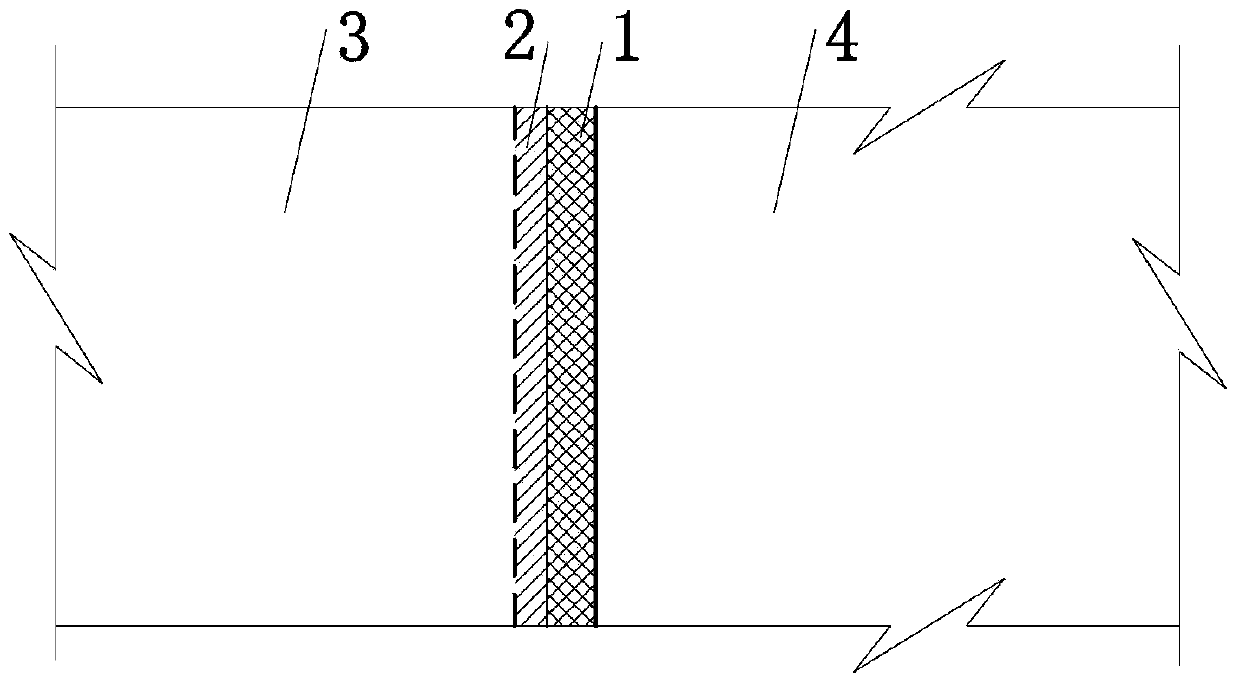

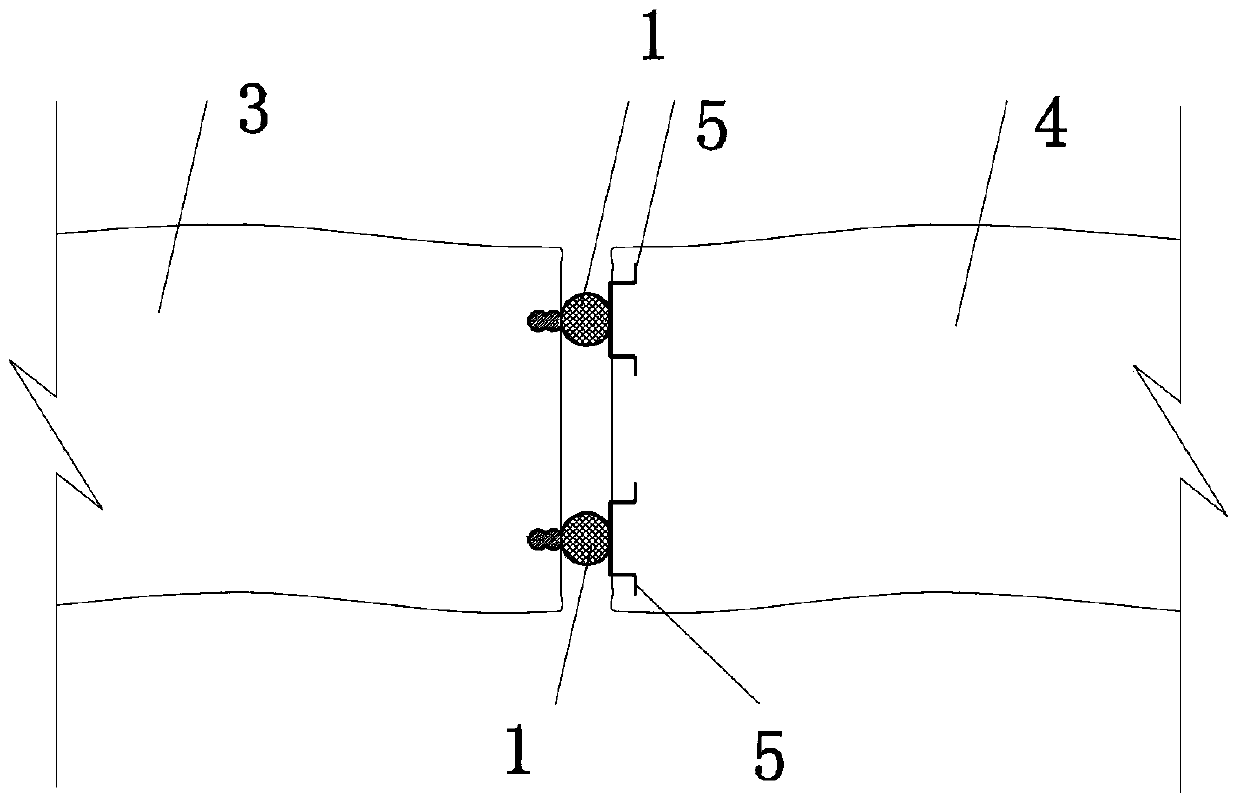

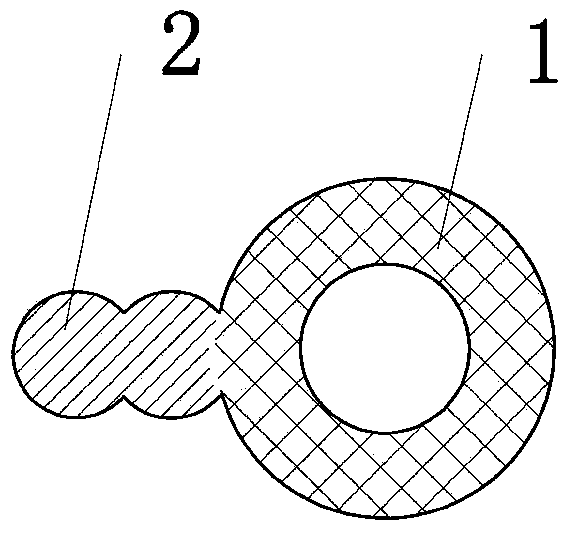

[0036] refer to Figure 1 to Figure 6 , a seam structure with anti-filtering function, including a seam assembly, the seam assembly includes an anti-filter part 1 and a connecting part 2, one side of the connecting part 2 is fixedly connected with a structural member 3 on one side, the The other side of the connecting part 2 is connected to one side of the reverse filter part 1, one side of the reverse filter part 1 is close to the structural member 3 on the one side, and the other side of the reverse filter part 1 is close to Lean on the other side structural member 4;

[0037] The reverse filter part 1 adopts a compressible and rebound reverse filter material, and fine pores are distributed on the reverse filter part. The relationship between the characteristic particle size of the protected soil is in line with the filter criterion, namely:

[0038] o 95 ≤Bd 85

[0039] In the formula, O 95 is the equivalent pore diameter of the reverse filter part, d 85 is the chara...

Embodiment 2

[0049] refer to Figure 1 to Figure 6 , a construction method of a seam structure, said construction method comprising the following steps:

[0050] (1) One end of the reverse filter part 1 is fixedly connected with the structural member 3 on one side through the connecting part 2;

[0051] The reverse filter part 1 adopts a compressible and rebound reverse filter material, and fine pores are distributed on the reverse filter part. The relationship between the characteristic particle size of the protected soil is in line with the filter criterion, namely:

[0052] o 95 ≤Bd 85

[0053] In the formula, O 95 is the equivalent pore diameter of the reverse filter part, d85 is the characteristic particle size of the protected soil, B is the coefficient, determined according to engineering experience, and takes 0.5~3;

[0054] (2) Install the one side structural member 3 fixed with the reverse filter part 1 in place, and then install the other side structural member 4, one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com