Intelligent submersible pump control box

A submersible pump and control box technology, applied in the field of intelligent submersible pump control system, can solve problems such as submersible pump control problems, and achieve the effect of prolonging the service life of equipment, reducing labor intensity of employees, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

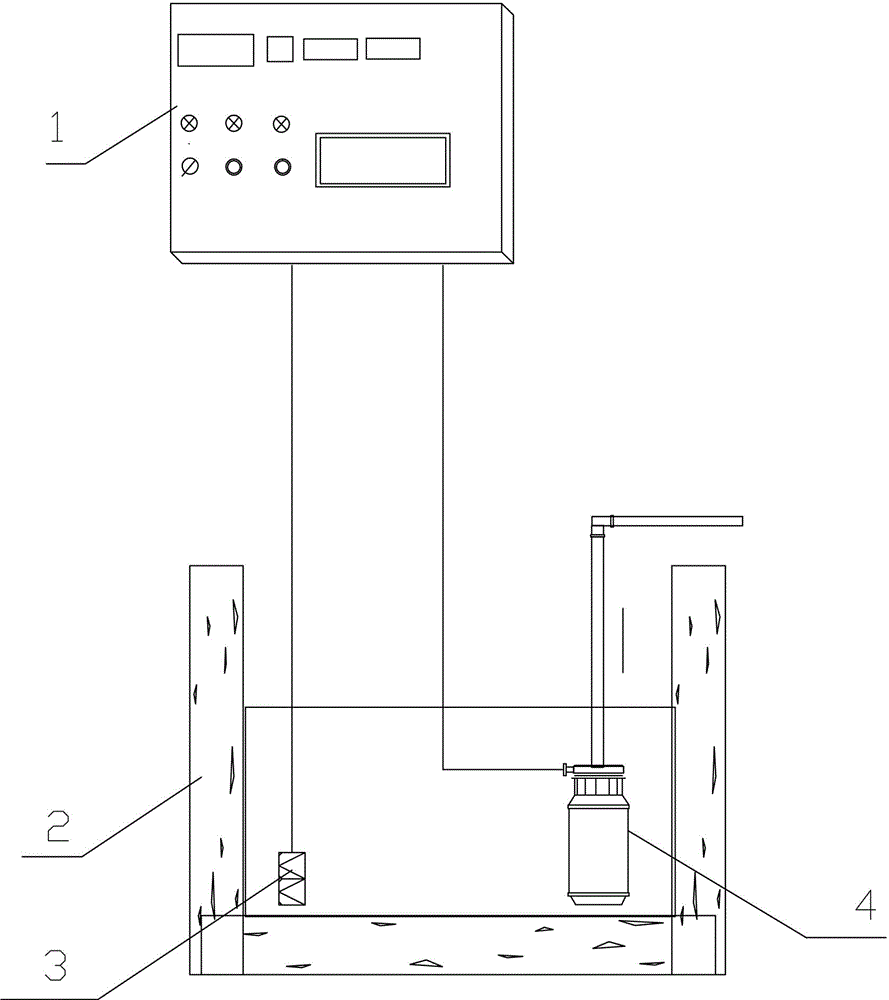

[0020] figure 1 It is a general diagram of the intelligent submersible pump control system of the present invention. exist figure 1 The middle liquid level control box 1 is connected to the submersible liquid level transmitter 3 through a special shielded cable, and the submersible pump 4 extracts the liquid inside the on-site pump pit 2 for drainage.

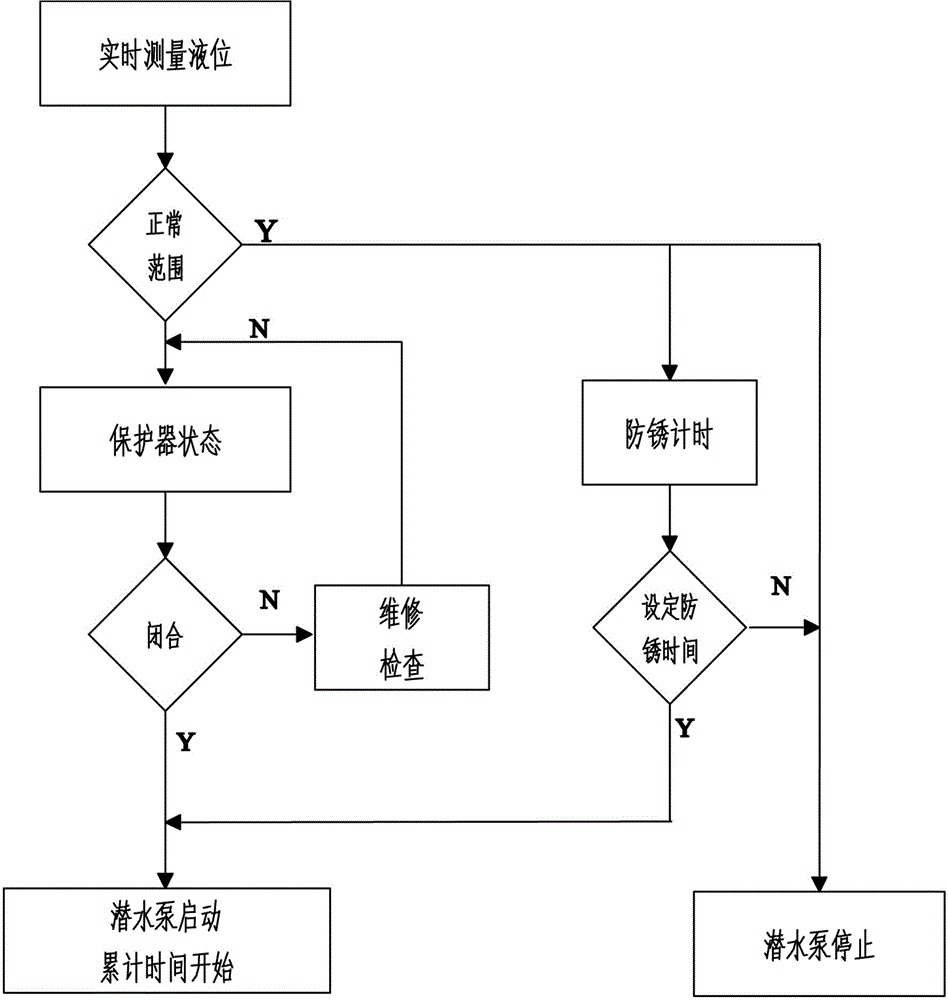

[0021] figure 2 It is the flow chart of the intelligent submersible pump control system of the present invention. The liquid level transmitter 3 measures the liquid level value in real time. If it is within the normal range, the anti-rust timing circuit starts to work, and the set time can be adjusted. After the set time is exceeded, the submersible pump will stop after 2 seconds for rust removal. The liquid level transmitter 3 measures the liquid level in real time. After the value exceeds the normal range, if the state of the motor protector 1RJ is within the normal range, the contactor is closed, the submersible pump 4 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap