Button-start mixed-flow pump station

A mixed-flow pump and mixed-flow technology, applied in the direction of driving pumps, pumps, pump control, etc., can solve the problems of complex start-up procedures, high labor costs, and difficult start-up of mixed-flow pump stations, and achieve convenient use and maintenance, low labor costs, and start-up procedures simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings, and the embodiments of the present invention include but are not limited to the following examples.

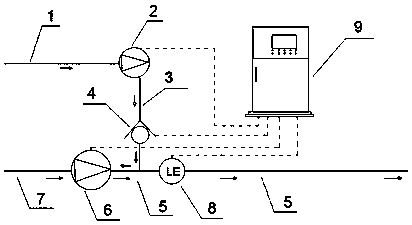

[0015] like figure 1 As shown, this embodiment includes a water suction pipe 1, a self-priming pump 2, an irrigation pipe 3, an irrigation valve 4, an outlet pipe 5, a mixed flow pump 6, an inlet pipe 7, a liquid level sensor 8 and a control system 9; one end of the water suction pipe 1 Connected to the water inlet end of the self-priming pump 2, the water outlet end of the self-priming pump 2 communicates with one end of the irrigation valve 4 through the irrigation pipe 3, and the other end of the irrigation valve 4 communicates with the side of the outlet pipe 5 connected to the outlet end of the mixed-flow pump 6, and its communication The port of the port is preferably located directly above the water outlet of the mixed flow pump 6. The liquid level sensor 8 is ins...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap