High-precision anhydrous micro-leakage detection device

A leak detection device, high-precision technology, applied in the direction of liquid tightness measurement using liquid/vacuum degree, by measuring the increase and deceleration rate of fluid, etc., can solve the impact of air tightness detection, affect the mental state of work, and cumbersome operation and other problems, to achieve the effect of accurate and precise air tightness detection, improve detection accuracy, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

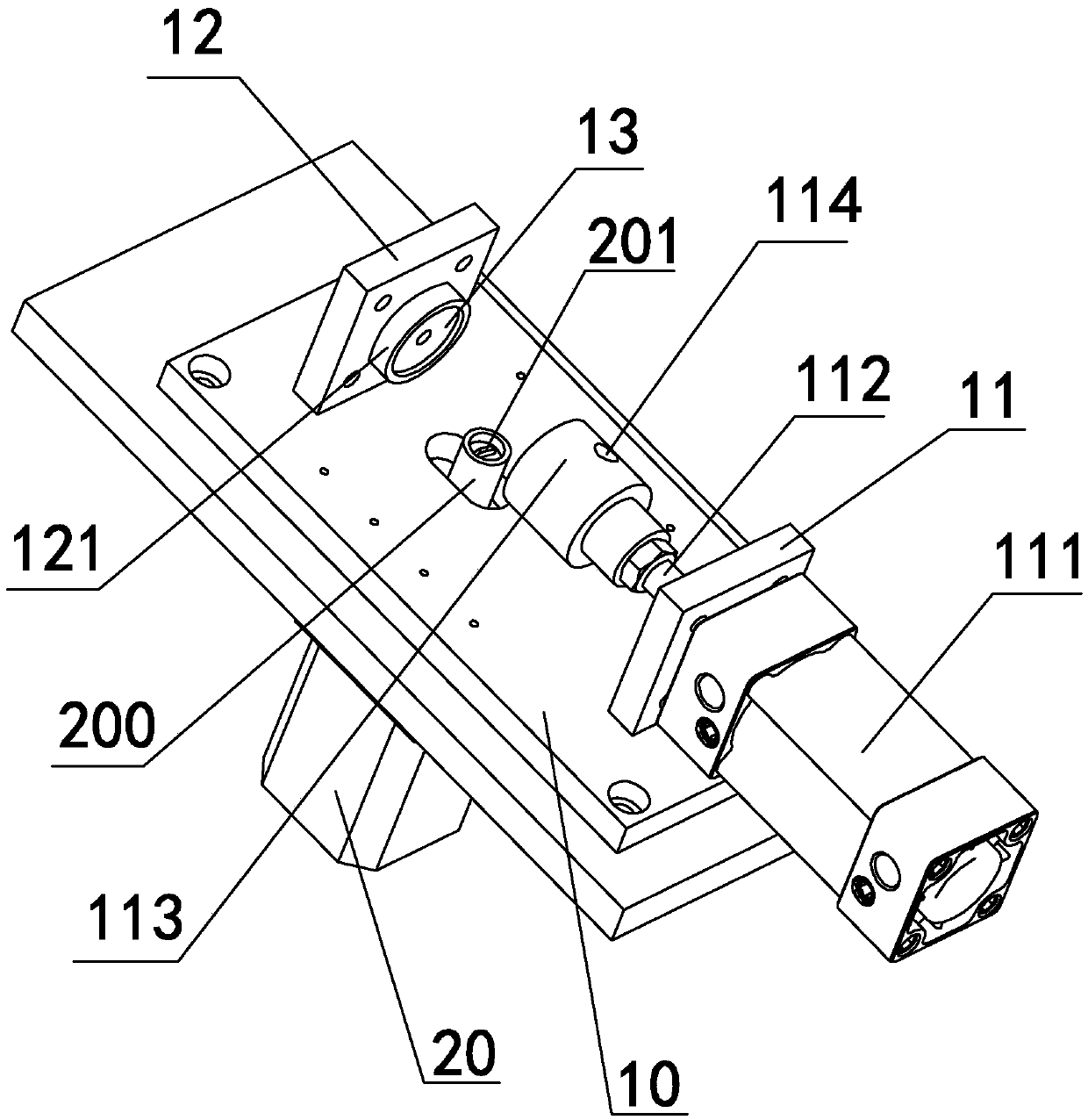

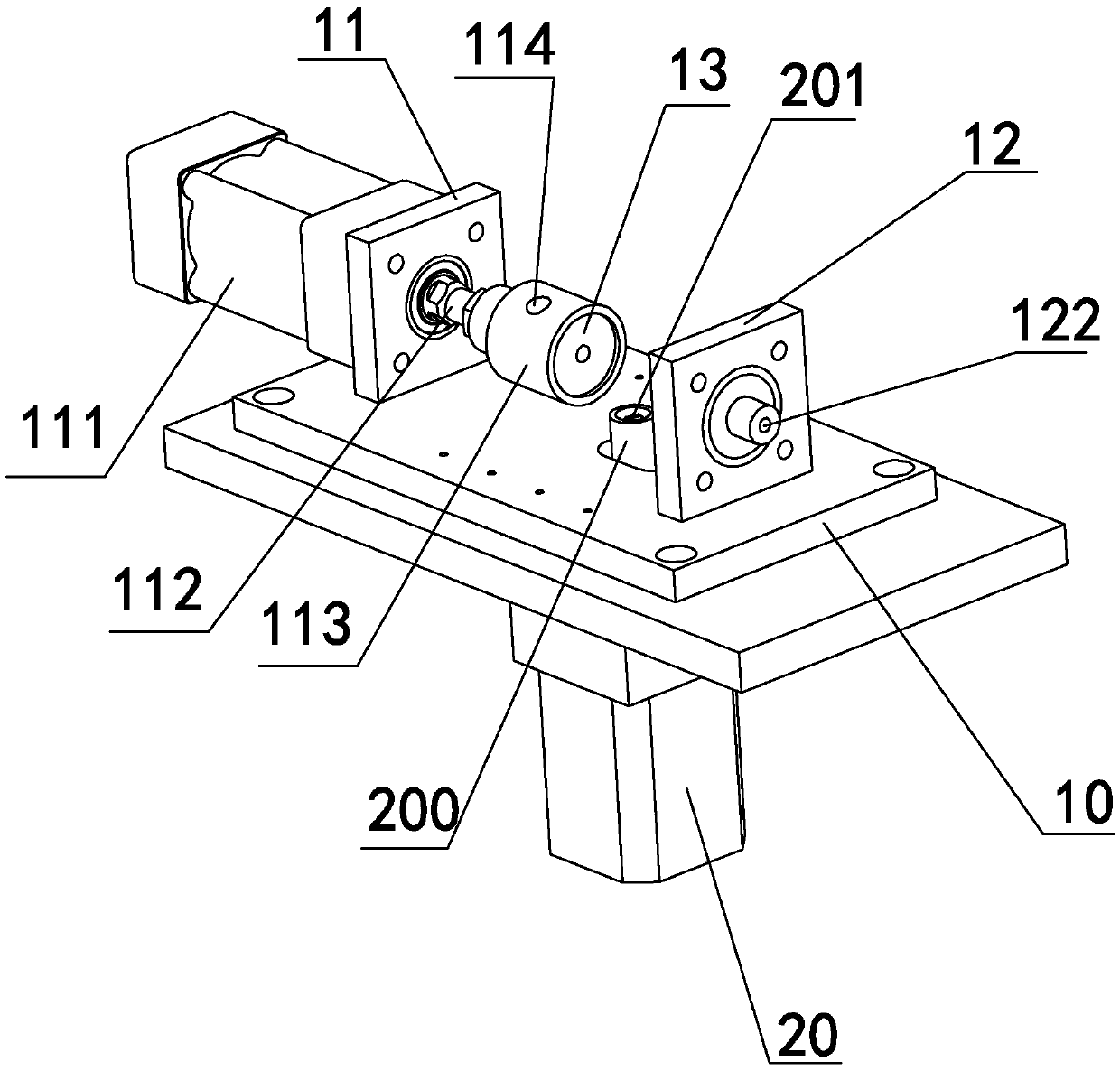

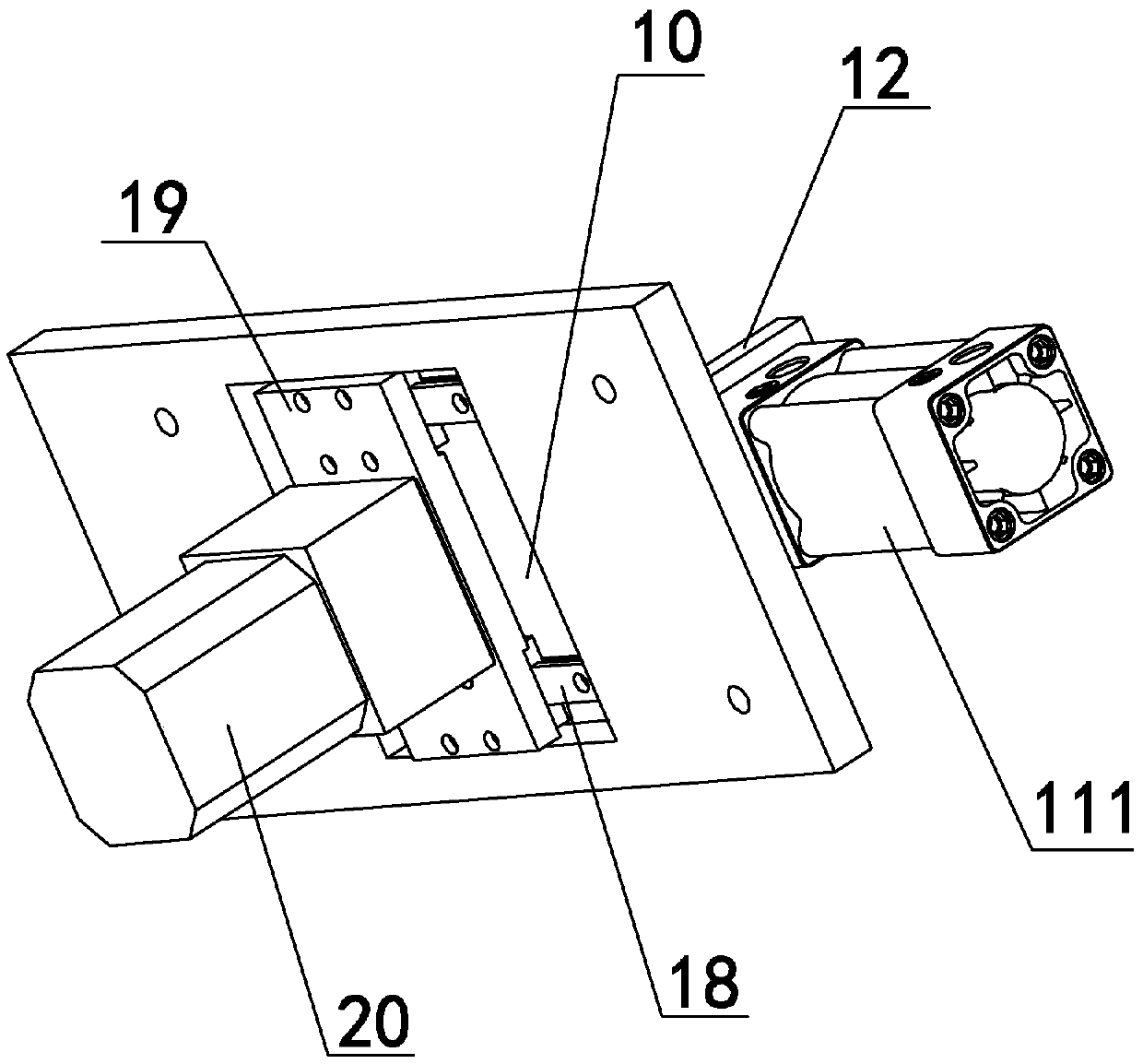

[0025] Such as Figure 1-4 As shown, it is a high-precision anhydrous micro-leakage detection device disclosed in the present invention. The substrate 10 is provided with a clamping mechanism, and the clamping mechanism is provided with an inflation hole 114 and a vent hole 122 that can be used to inflate and exhaust the object to be detected. The inflation hole 114 and the deflation hole 122 are respectively connected with an air path detection and control mechanism for controlling inflation, deflation and detection of air pressure difference, and an auxiliary knob mechanism is provided on one side of the clamping mechanism.

[0026] Such as Figure 1-3 As shown, the specific structure of the clamping mechanism is: one side on the front of the substrate 10 is fixed with a main vertical board 11, and the other side is fixed with a secondary vertical board 12, and the main vertical board 11 and the secondary vertical board 12 are arranged oppositely, and There is a certain int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com