Method for determining optimum water content of emulsified asphalt cold-recycling mixture

A technology of cold recycled mixture and optimal water content, applied in the direction of material inspection products, etc., can solve the problems of no clear theory and indicators, unreachable, cold recycled mixture design without uniform specifications, etc., to achieve improved mixing Composite performance and compaction performance, the effect of simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

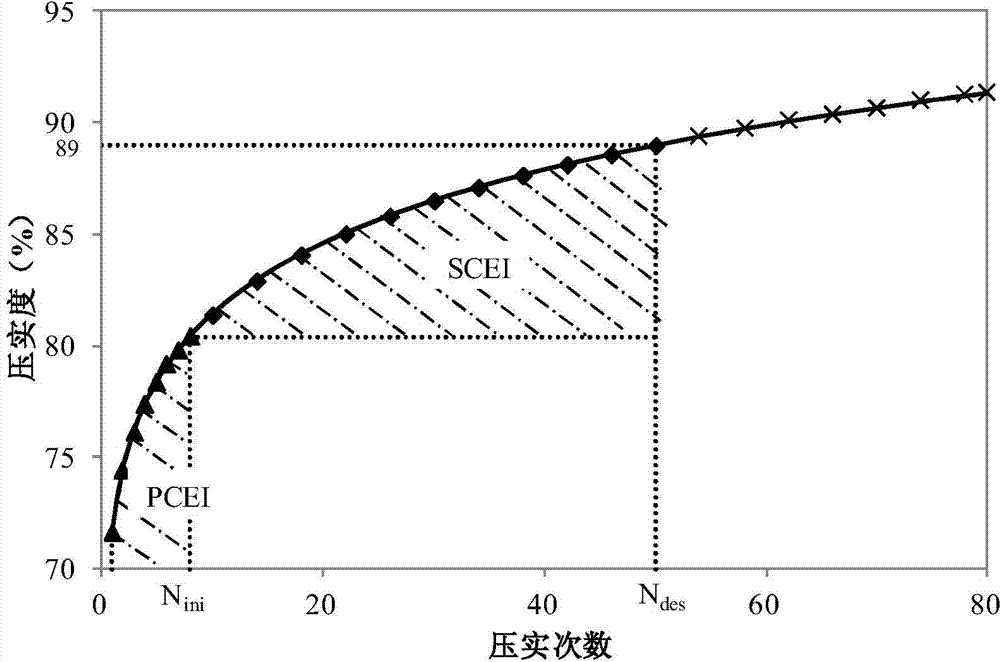

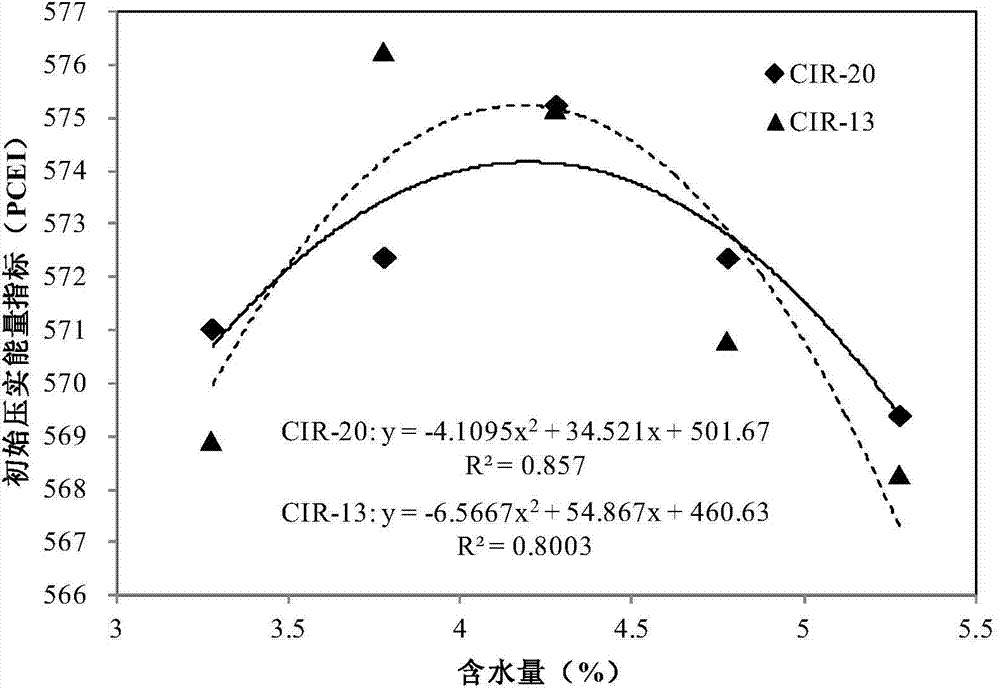

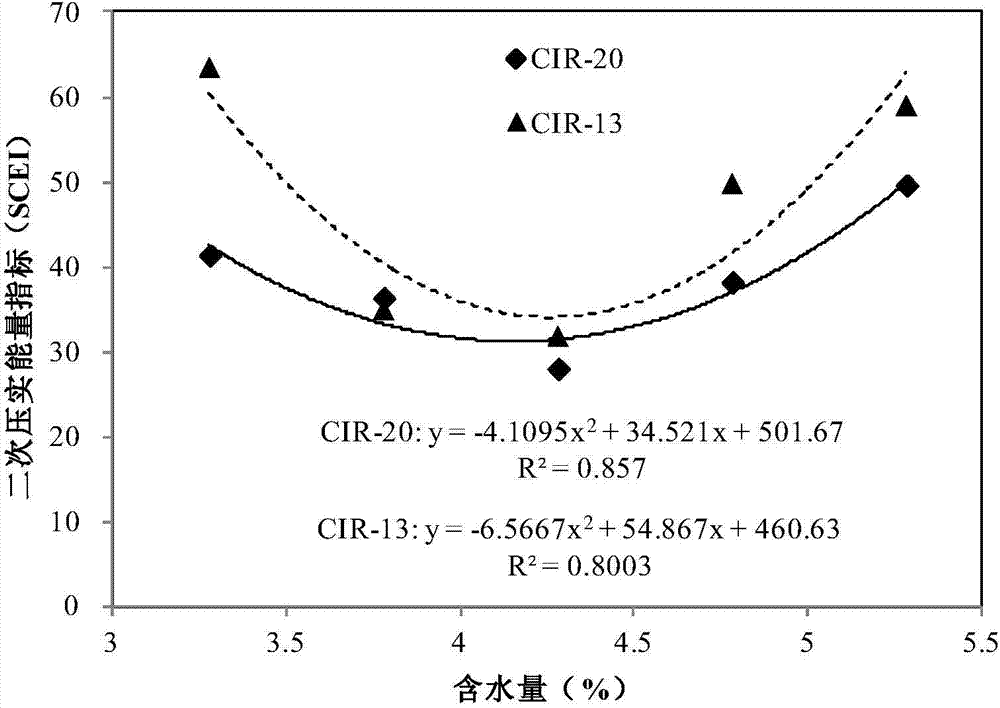

[0028] 1) Determine the water content range and draw the compaction curve

[0029] Two typical emulsified asphalt cold in-situ recycled mixture gradations CIR-20 and CIR-13 were selected for rotary compaction experiments. The total water content includes the added water, the water content in the emulsified asphalt and the water content in the old material. According to experience, 3% water is generally added to the in-situ cold recycled mixture. In order to evaluate the impact of water content on the pressure of the cold recycled mixture Influenced by the actual characteristics, a total of five sets of test pieces were made, and 2.0%, 2.5%, 3.0%, 3.5%, 4% (accounting for the percentage of the old asphalt mixture) were selected as the added water content, and the corresponding total water content was respectively 3.28%, 3.78%, 4.28%, 4.78%, 5.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com