Method and device for measuring elastic probe array multi-channel resistance

An elastic probe and resistance measurement technology, applied in the direction of measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve problems such as not being able to save time, achieve fast non-destructive measurement, shorten measurement time, and improve spatial resolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

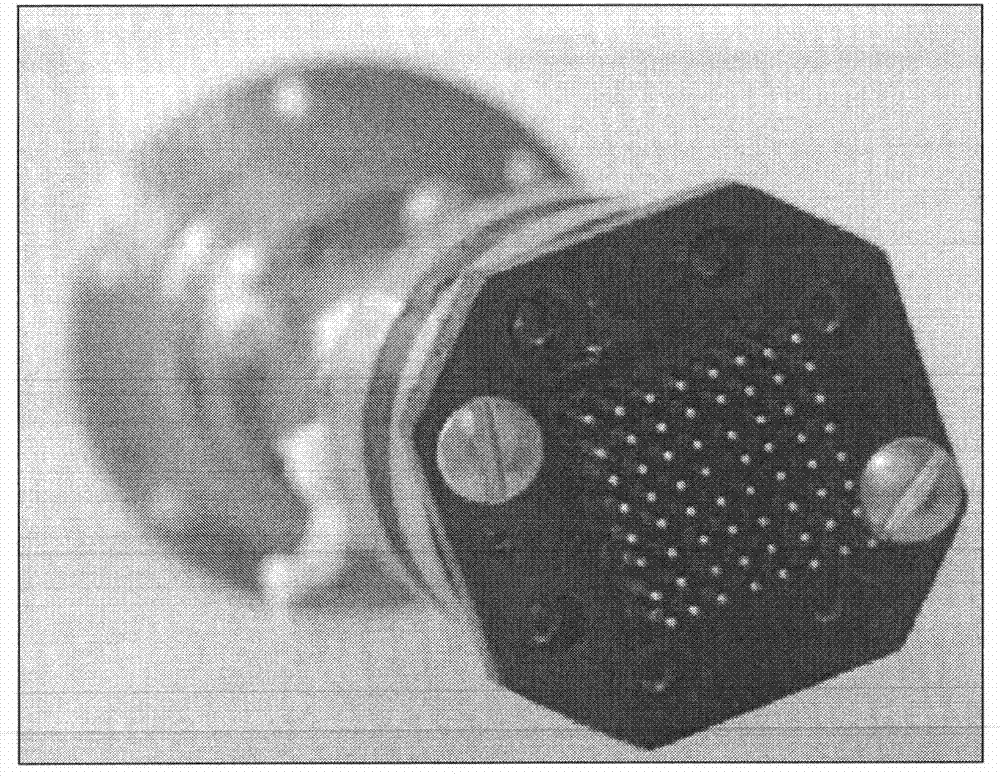

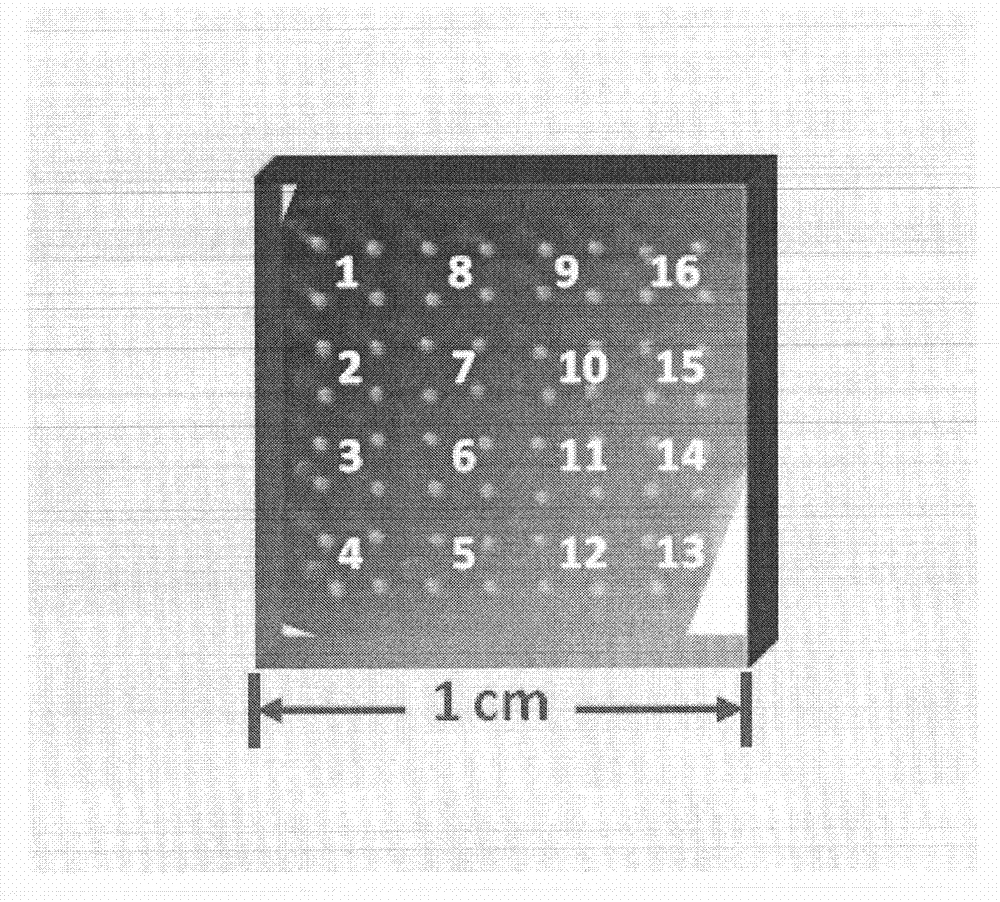

[0016] will be measured as figure 1 The elastic probe assembly shown in , is pressed directly against the sample and placed into a temperature or magnetic field measurement platform. The elastic probe device has a square measurement area of 1 cm × 1 cm, the above-mentioned measurement area includes an elastic probe array, and the elastic probe array is an n × n microspring probe array, where n=4 × k, k is greater than An integer equal to 2.

[0017] figure 1 The elastic probe arrays shown in include but are not limited to 8×8 microspring probe arrays, that is, 64 probes are integrated in the above-mentioned 1cm×1cm square measurement area, and between every two nearest neighbor measurement points The spacing is less than 1mm.

[0018] Corresponding to the above-mentioned elastic probe device, for example, the binary composite film prepared by the co-magnetron sputtering method is cut into small pieces of 1 cm×1 cm, and the distance between every two nearest neighbor measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com