Material moisture content measuring device based on microwave cavity physical wave and measuring method thereof

A measuring device and technology for moisture content, applied in the field of microwave applications, can solve the problems of unmeasured sample detection, space microwave reflection, transmission and scattering, large volume, etc., and achieve the effect of good portability and fast non-destructive measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

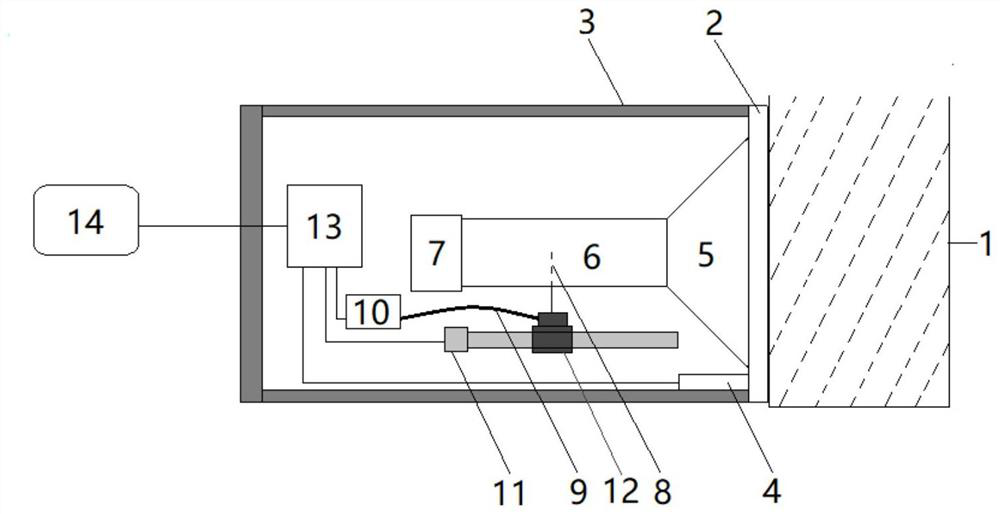

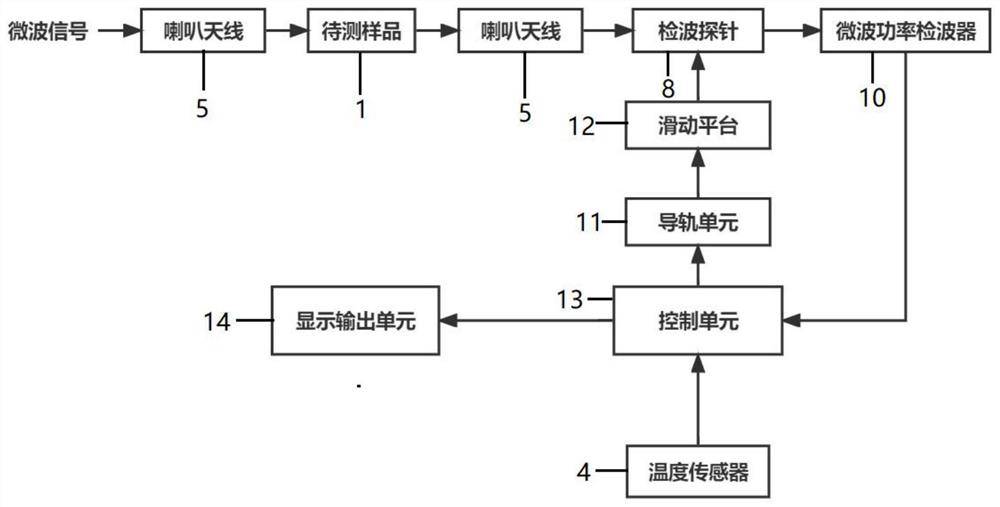

[0060] like figure 1 As shown, a material moisture content measurement device based on microwave cavity detection includes a sample to be tested 1, a front panel 2, a display output unit 14, a device casing 3, a temperature sensor 4 located inside the device casing 3, a horn antenna 5, Slotted waveguide 6, microwave resonant cavity 7, detection probe 8, coaxial line 9, microwave power detector 10, guide rail unit 11, sliding platform 12 and control unit 13; wherein, the front panel 2 is fixedly installed on the device casing A temperature sensor 4 is also provided on the front-end panel 2 inside the device casing 3; the horn antenna 5, the slotted waveguide 6 and the microwave resonant cavity 7 are connected end-to-end in sequence, and one end of the detection probe 8 Vertically fixed on the sliding platform 12, the sliding platform 12 is slidably connected to the guide rail unit 11, the guide rail unit 11 is composed of a sliding rail and a motor connection, the sliding platf...

Embodiment 2

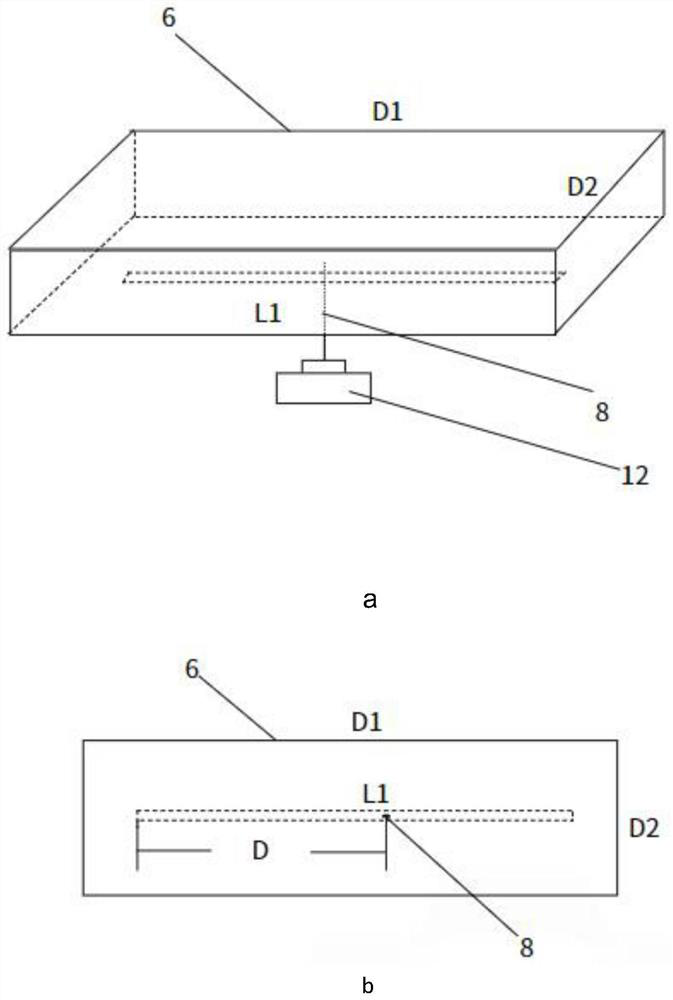

[0075] This embodiment describes the specific structures of the slotted waveguide and the detection probe. like figure 2 As shown, a specific combined structure of the slotted waveguide 6 and the detection probe 8 has a narrow long slot in the middle of the lower surface of the waveguide cavity, the slot length L1 is 50mm, and the slot width is 1mm. The detection probe 8 penetrates deep into the slot to measure the microwave signal inside the slotted waveguide 6 . The detection probe 8 realizes the movement measurement inside the waveguide cavity through the movement of the sliding platform 12 . The distance between the detection probe 8 and the initial position of the left slot is D. When the voltage measured at a certain point is the minimum value of the traveling standing wave, the corresponding moving distance D is D. m .

Embodiment 3

[0077] In this example, wheat is used as the measurement object to illustrate the specific measurement method of the measuring device. The initial moisture content of the wheat after natural drying is 9%, and 6 wheat samples with different moisture contents are finally obtained by adding water to the samples and stirring continuously. , the moisture content varies from 9% to 28.4%.

[0078] A measurement method of a material moisture content measurement device based on microwave cavity detection, the specific steps are as follows:

[0079] S1, microwave space wave signal continuous measurement;

[0080] The control unit 13 controls the motor in the guide rail unit 11 to rotate, so that the detection probe 8 is gradually moved closer to the wheat. Acquisition, comparison by the control unit 13, recording the maximum voltage V max , the minimum value V min and the moving distance D of the detection probe 8 corresponding to the minimum value m , calculate the voltage standing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com